Adhesion promoter of optical fiber coating and preparation method thereof

An adhesion promoter and coating technology, which is used in the field of light coating adhesion promoter and its preparation, can solve the problem that the adhesion promoter cannot be dispersed in water, etc., achieve good water-based dispersion, improve adhesion, and promote polymerization speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

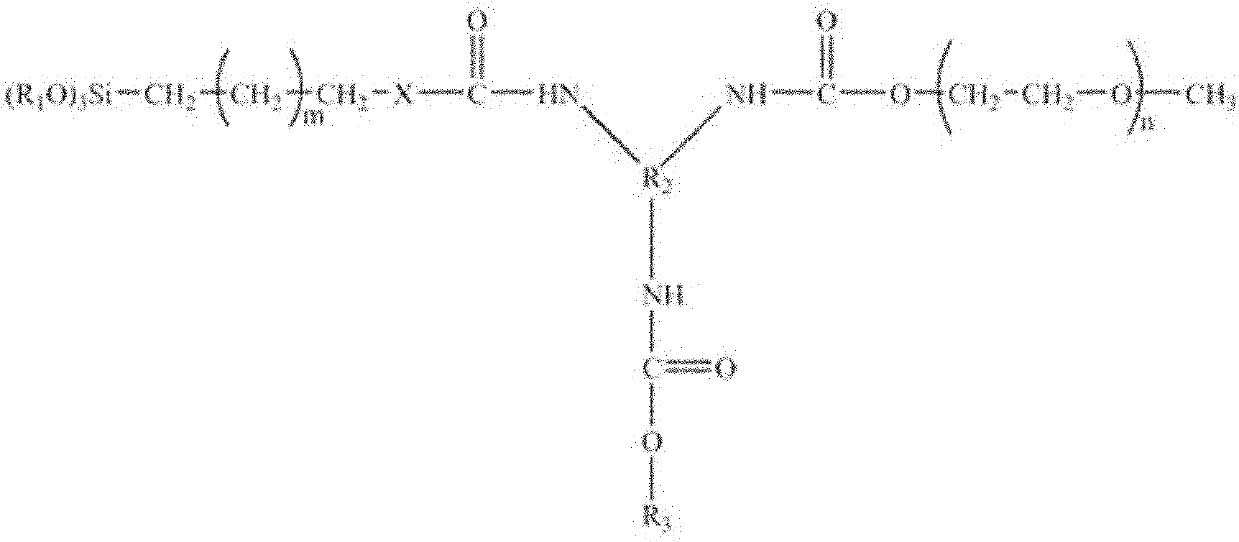

[0036] The present invention also provides a preparation method of an optical fiber coating adhesion promoter, comprising:

[0037] Under nitrogen protection, add 1 mol of polyethylene glycol monomethyl ether to 3 mol of diisocyanate cyclic trimer, control the reaction temperature at 80-90°C, and react for 2-3 hours to obtain the first intermediate product;

[0038] Cool down to 75-80°C, add a mixture of 1 mol of hydroxyacrylate and 0.0003 mol of p-hydroxyanisole to the first intermediate product, and react for 1.5-2.5 hours to obtain the second intermediate product;

[0039] Cool down to 50-65° C., add 0.0004 mol of dibutyltin dilaurate and 1.1-1.3 mol of siloxane compound to the second intermediate product, and react for 1-8 hours to obtain a water-based adhesion promoter.

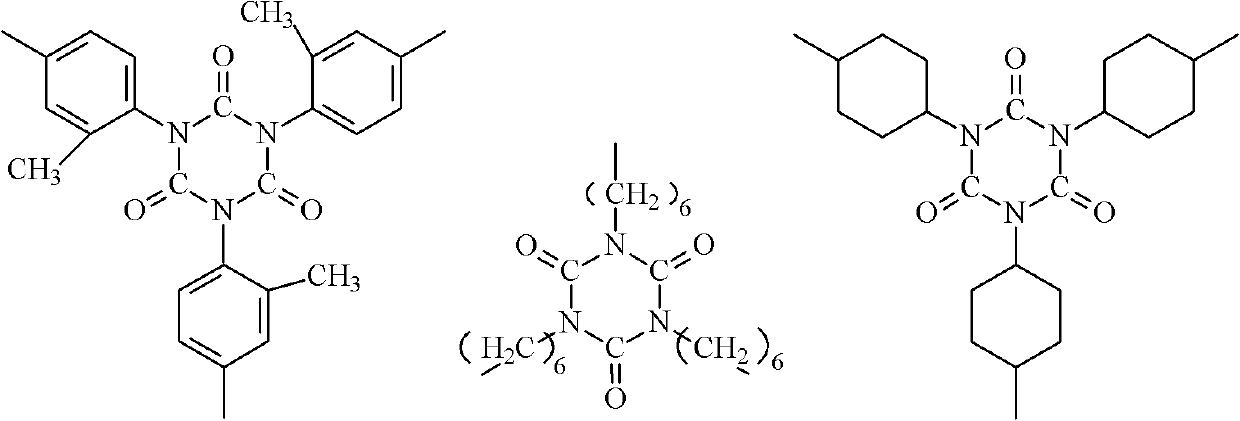

[0040] The diisocyanate cyclic trimer is preferably an aromatic or aliphatic cyclic trimer. Among them, the aromatic diisocyanate can be selected from 2,4-toluene diisocyanate cyclic trimer, 2,6-toluene...

Embodiment 1

[0049] Embodiment 1: water-based adhesion promoter

[0050] Under nitrogen protection, add 1 mol of polyethylene glycol monomethyl ether (number average molecular weight: 350 Daltons) into Desmodur N3390 with 3 mol of isocyanate content, control the reaction temperature at 90°C, and react for 2.5 hours; then, cool down to 85°C , add a mixture of 1mol hydroxyethyl acrylate and 0.0003mol p-hydroxyanisole, and react for 1.5 hours; cool down to 65°C, add 0.0004mol dibutyltin dilaurate and 1.3mol 3-mercaptopropyltrimethoxysilane, and react After 8 hours, the adhesion promoter WS 1 was obtained.

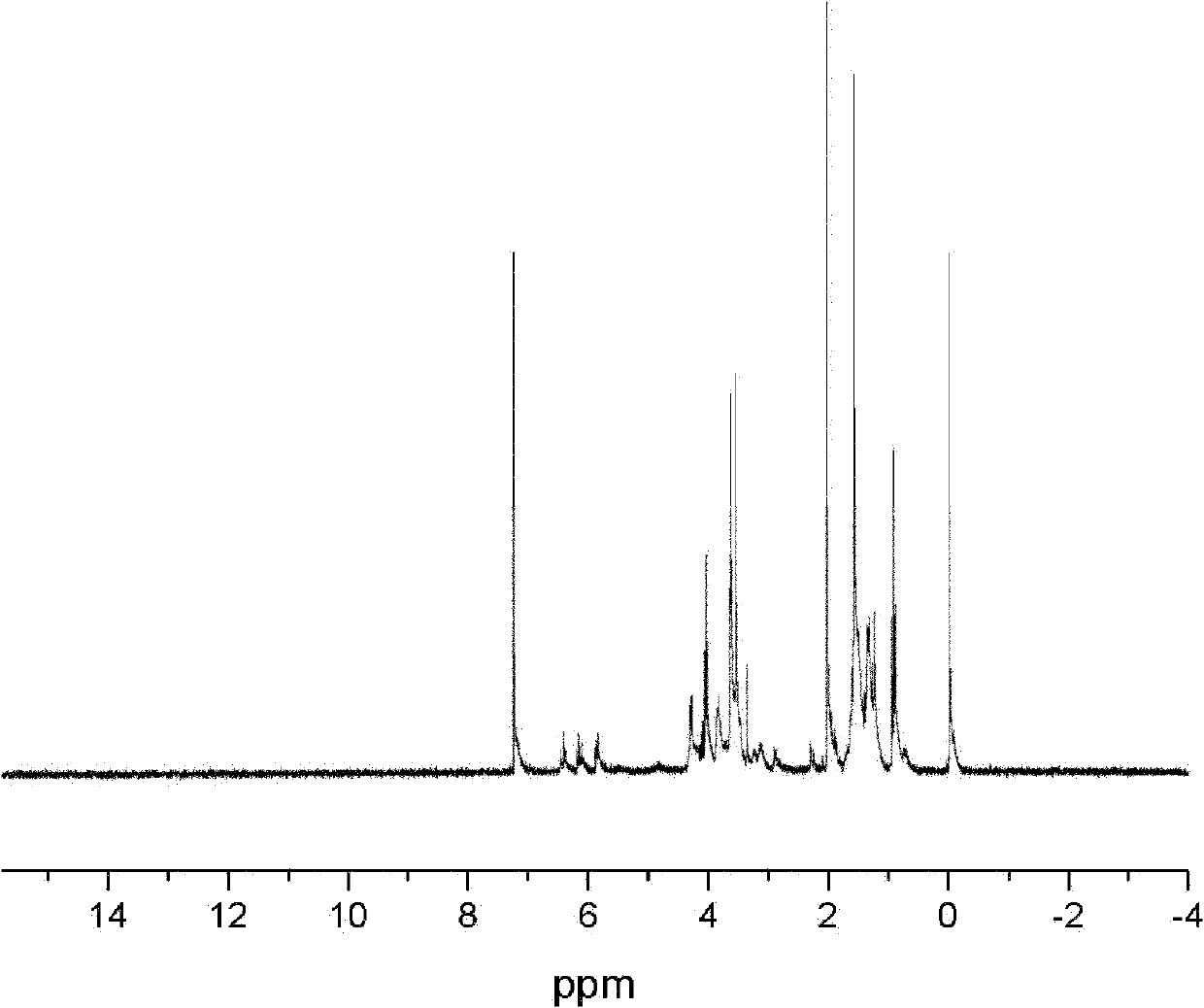

[0051] Carry out nuclear magnetic resonance to described modified polyurethane acrylate, the result sees figure 1 , figure 1 The proton nuclear magnetic resonance spectrum of the water-based adhesion promoter provided for the embodiments of the present invention, by figure 1 It can be seen that its hydrogen spectrum is as follows: 1 H NMR: 0.91ppm, 1.24ppm, 1.32ppm, 1.57ppm, 2.02ppm, 2...

Embodiment 2

[0052] Embodiment 2: water-based adhesion promoter

[0053] Under nitrogen protection, add 1 mol of polyethylene glycol monomethyl ether (number average molecular weight: 76 Daltons) into Desmodur Z4470 with 3 mol of isocyanate content, and control the reaction temperature at 100°C for 2 hours; then, cool down to 80°C , add a mixture of 1mol pentaerythritol triacrylate and 0.0003mol p-hydroxyanisole, and react for 2 hours; cool down to 50°C, add 0.0004mol dibutyltin dilaurate and 1.3mol 3-aminopropyltriethoxysilane, React for 1 hour to obtain the adhesion promoter WS2.

[0054] Carry out nuclear magnetic resonance to described aqueous adhesion promoter, its hydrogen spectrum is as follows: 1 H NMR: 0.59ppm, 1.13ppm, 1.45ppm, 1.71ppm, 2.95ppm, 3.16ppm, 3.20ppm, 3.24ppm, 3.55ppm, 3.65ppm, 3.98ppm, 4.07ppm, 4.25ppm, 5.80ppm, 6.05ppm, 6.43ppm . It can be seen that the modified polyurethane acrylate is a modified polyurethane acrylate with a structure of formula (I), wherein, R ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com