Rubber spring material for automobile braking double-cavity serial brake valve and preparation method thereof

A rubber spring and automobile braking technology, which is applied in the field of rubber spring materials for automobile brake double-chamber series brake valves and their preparation, can solve problems such as dependence on imports, save foreign exchange, prevent material shortage and flow marks, and achieve excellent performance. Effects of aging-resistant materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

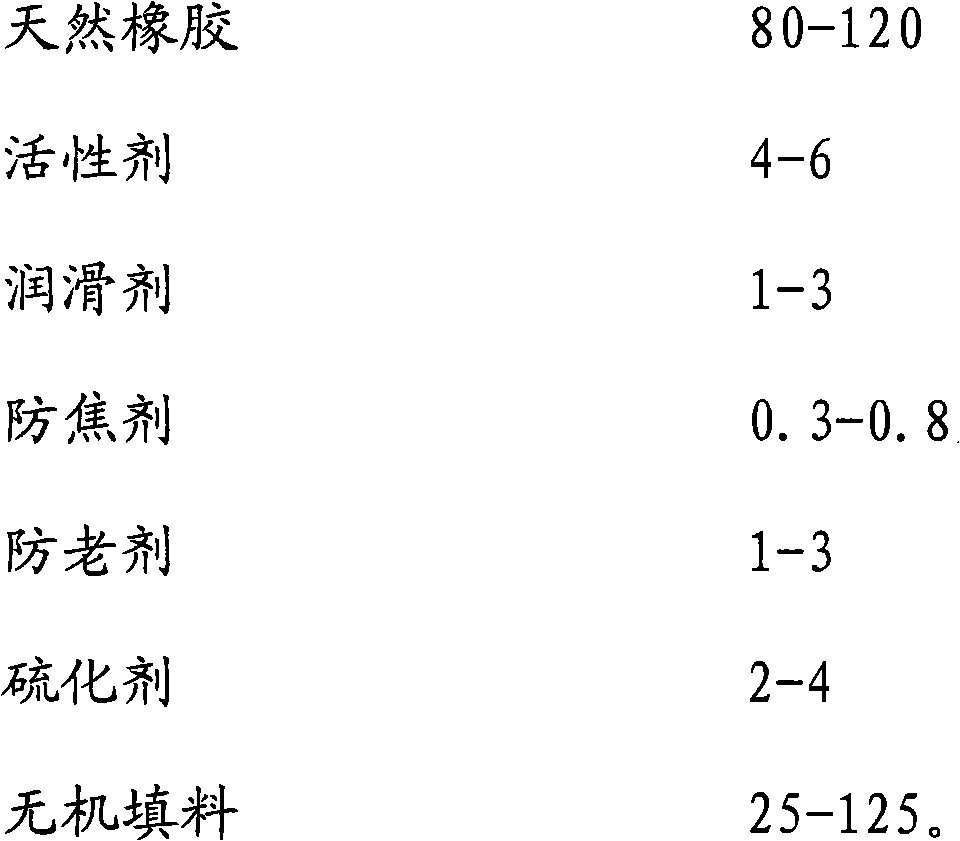

[0042] Each raw material component is by weight ratio:

[0043]

[0044] The active agent is imported zinc oxide; the lubricant is imported microcrystalline wax; Grind carbon black. Its preparation method is as follows:

[0045] (1), each raw material component is mixed according to the weight ratio, and the molded part is pressed;

[0046] (2) Open the mold, put in the molded parts, and vulcanize. The vulcanization temperature is 165-175°C, the time is 330s, and the pressure is 80-120kgf / cm 2 ;

[0047] (3), the vulcanized molded parts are punched and trimmed;

[0048] (4) The die-cut formed parts are inspected, packaged, and put into storage to obtain products.

Embodiment 2

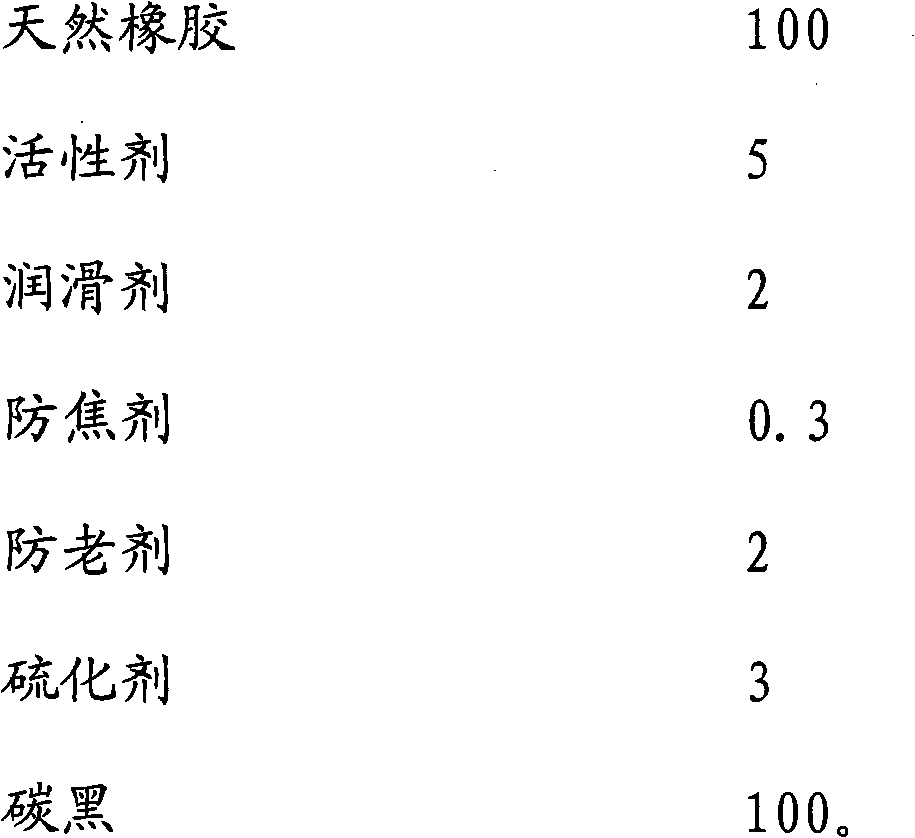

[0050] Each raw material component is by weight ratio:

[0051]

[0052] The preparation method is the same as in Example 1.

Embodiment 3

[0054] Each raw material component is by weight ratio:

[0055]

[0056] The preparation method is the same as in Example 1.

[0057] According to the above raw material ratio and preparation process, the rubber spring for automobile brake double chamber series brake valve has a strength of 20MPA, a tear strength of 31KN / m, and low compression deformation (70°C × 24h, 25% compression ) is 12%, brake fluid resistance (70°C×70h) and aging resistance (70°C×24h) are +1 and +3 respectively.

[0058] The acquisition of the above-mentioned excellent properties should be the result of the synergistic effect of the various components of the rubber raw material of the present invention, that is, the present invention achieves far more than Technical effects of prior art.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com