Multifunctional sludge formation slitting machine

A technology of sludge forming and strip cutting machine, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., which can solve the problems of low production efficiency and limited application range, and achieve the effect of improving efficiency and expanding application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

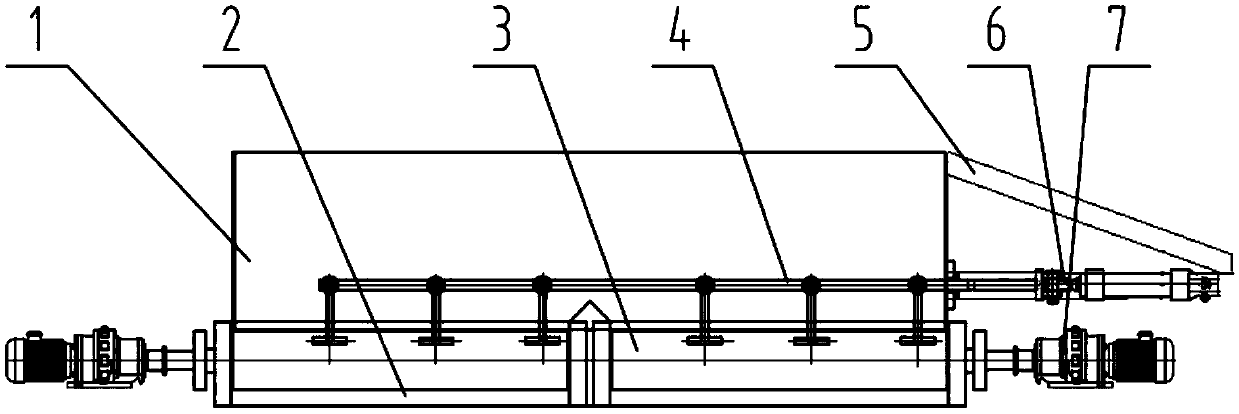

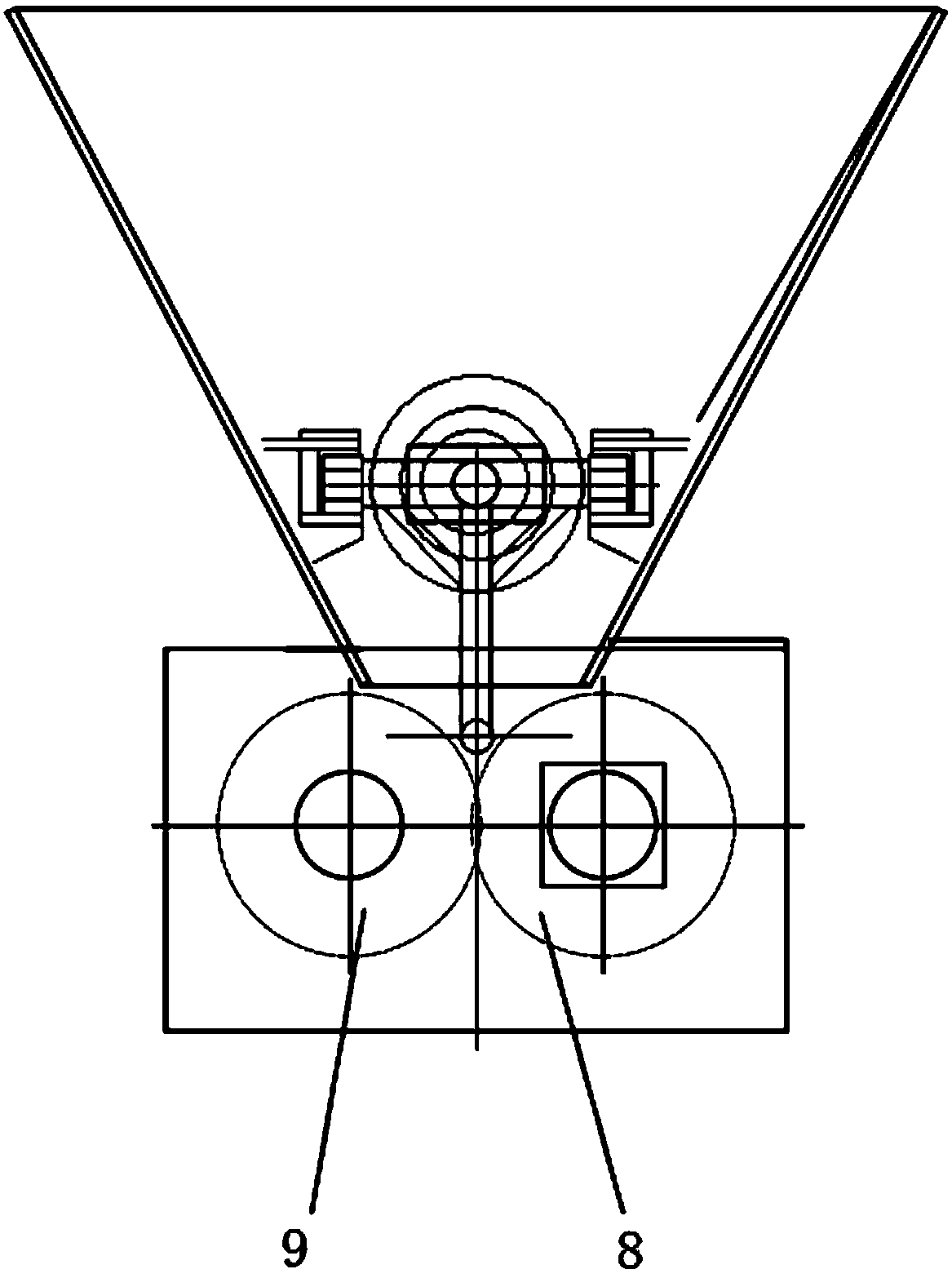

[0016] like figure 1 As shown, a multi-purpose sludge forming and cutting machine can process three types of sludge: municipal sludge, chemical sludge, and electroplating sludge. The forming cavity 2 is connected to the feeding device 1, and the forming cavity 2 is used as a supporting structure and an operating space. There is a forming nip roller 3 inside it. The forming nip roller 3 is composed of two groups, and each group is passed by a driving wheel 8 and a driven wheel 9. The gears are occluded and connected side by side. The forming nip roller 3 is connected to the electrical control device 7 used to make it rotate and control its number of revolutions. The upper part of the forming nip roller 3 is connected to the telescopic device 4. The drooping flat scraper on the top drives the drooping flat scraper to reciprocate through the telescopic rod, thereby offsetting the viscosity of the material, so that the material can be supplied continuously. connect.

[0017] The...

Embodiment 2

[0026] This embodiment is the application of the present invention in a heat pump drying system with a water content of chemical sludge from 65% to 25% and a treatment rate of 80 tons per day. The structure of each part of the device and the connection relationship are all the same as in Embodiment 1, and the difference is:

[0027] The driven wheel rotates at a speed of 40 rad / min. The bite groove of the forming nip roller is a strip block with a size of 10*10mm and a thickness of 8mm. The frequency of the telescopic device is 25 times / min. It is between 0 and 100mm. The fixing device is composed of Q235-B steel and plate, the steel is 40 channel steel, and the thickness of the plate is 10mm. Its parameters are selected within the design range and designed to ensure that the working conditions are met.

Embodiment 3

[0029] This example is the application of the present invention in a heat pump drying system where the water content of electroplating sludge is treated from 75% to 20%, and the treatment rate is 30 tons per day. The structure of each part of the device and the connection relationship are all the same as in Embodiment 1, and the difference is:

[0030] The driven wheel rotates at a speed of 30 rad / min. The nip groove of the forming nip roller is cake-shaped, with a diameter of 12 mm and a thickness of 6 mm. The frequency of the telescopic device is 20 times / min, and the telescopic range is between 0 and 50 mm. , The fixing device is composed of Q235-B shaped steel and plate, the shaped steel is 40 channel steel, and the thickness of the plate is 8mm. Its parameters are selected within the design range and designed to ensure that the working conditions are met.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com