Metal-reinforced composite decorative glass plate

A technology of metal strengthening and composite glass, which is applied in the field of decorative materials, can solve problems such as high requirements and complicated manufacturing processes, and achieve the effects of high tensile strength, good applicability and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The metal-strengthened composite glass decorative panel of this embodiment has a three-layer structure, see figure 1 , the surface layer is a glass thin plate layer (1), the bottom layer is a metal strengthening layer (2), and the middle layer is bonded with an adhesive layer (3).

[0040] Wherein the vitreous thin plate layer (1) is a thin plate layer made of brittle vitreous materials such as glass plates, tempered glass plates, and glass-ceramic plates. The initial state of the thin plate layer is sheet-like, and the thickness is less than 3 mm. The glass thin plate layer (1) used here can undergo various beautification treatments, such as coating, baking varnish, printing, sandblasting, frosting, hand-painting, engraving and the like.

[0041] Among them, the metal strengthening layer (2) refers to the structural layer made of metal materials with higher strength and good processing performance. The metal mentioned here refers to copper, aluminum, iron and correspon...

Embodiment 2

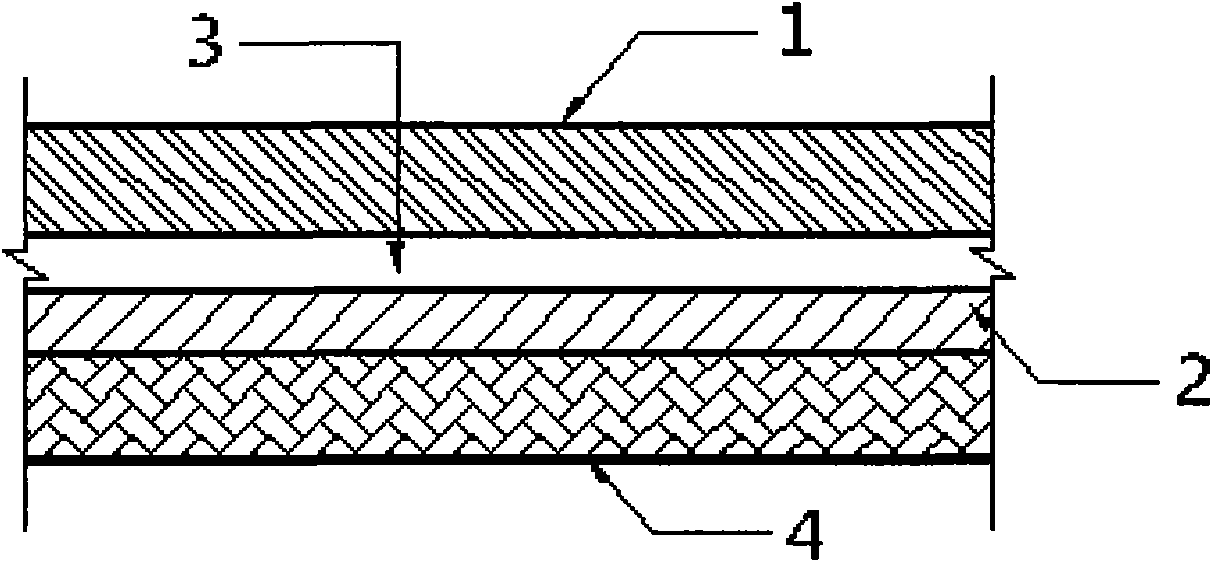

[0043] The metal-strengthened composite glass decorative panel of the present embodiment has a four-layer structure, see figure 2 , the surface layer is a glass thin plate layer (1), the middle is a metal reinforcement layer (2), bonded by the adhesive layer (3), and a functional material layer (4) is added at the bottom, which not only increases the overall rigidity of the plate , to protect the metal strengthening layer (2), and to increase its bonding strength with the surface to be decorated.

[0044] Wherein the vitreous thin plate layer (1) is a thin plate layer made of brittle vitreous materials such as glass plates, tempered glass plates, and glass-ceramic plates. The initial state of the thin plate layer is sheet-like, and the thickness is less than 3 mm. The glass thin plate layer (1) used here can undergo various beautification treatments, such as coating, baking varnish, printing, sandblasting, frosting, hand-painting, engraving and the like.

[0045] Among them,...

Embodiment 3

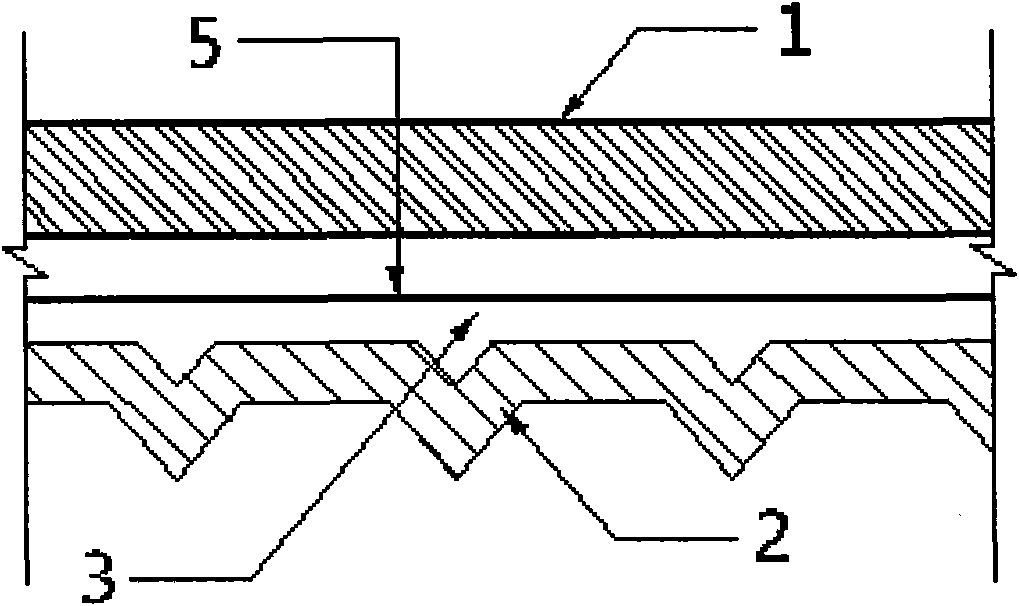

[0047] The metal-strengthened composite glass decorative panel of the present embodiment has a four-layer structure, see image 3 , the surface layer is a glassy thin plate layer (1), the bottom surface is a metal strengthening layer (2), bonded by an adhesive layer (3), and a pattern layer (5) is added to the adhesive layer (3), which can To increase the decoration of the board, it can be made of metal sheet, reflective film, fiber cloth and other materials.

[0048] Wherein the vitreous thin plate layer (1) is a thin plate layer made of brittle vitreous materials such as glass plates, tempered glass plates, and glass-ceramic plates. The initial state of the thin plate layer is sheet-like, and the thickness is less than 3 mm. The glass thin plate layer (1) used here can undergo various beautification treatments, such as coating, baking varnish, printing, sandblasting, frosting, hand-painting, engraving and the like.

[0049]Among them, the metal strengthening layer (2) refer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com