Microfluid chip and spinning method thereof

A technology of microfluidic chips and microfluidic channels, which is applied in the fields of bionics, textile fibers, material science, and microfluidics, can solve the problem that spider silk cannot be obtained in large quantities, and achieve the effect of improving the degree of bionics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] With the mass percent concentration of 30% regenerated silk fibroin aqueous solution as the spinning solution, the spinning solution was injected into the microfluidic chip at a flow rate of 0.5 μL / min at a temperature of 30 ° C, and the microfluidic channel of the microfluidic chip After exit extrusion, the dry spinning process is adopted, solidified into filaments in the air and wound on the upper roller; the air gap from the spinneret to the winding roller is 1cm, and the winding speed is 1cm / s.

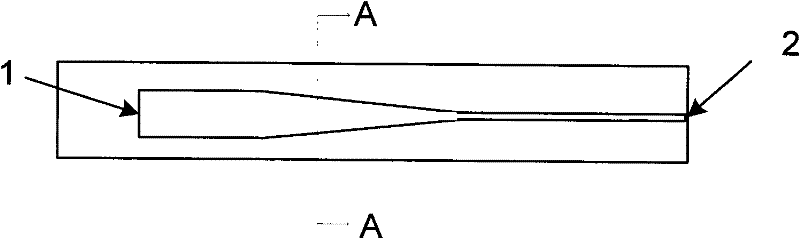

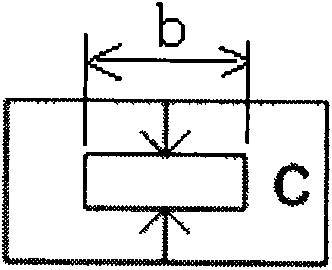

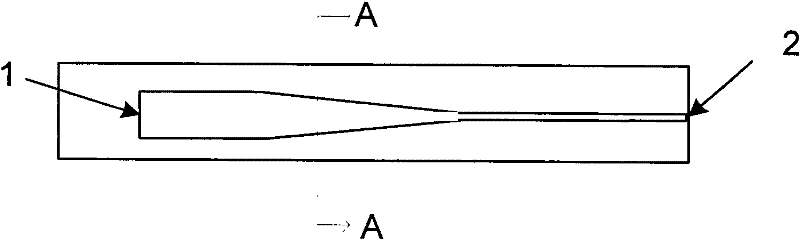

[0032] The microfluidic chip includes a substrate and a diaphragm, the diaphragm has a groove, and the surface of the diaphragm with the groove is bonded to the substrate to form a microfluidic channel; the depth c of the whole process of the microfluidic channel is equal to 10 μm, the width b of the microfluidic channel gradually and continuously decreases from the inlet to the outlet, the inlet width is 2 mm, and the outlet width is 10 μm. In the microfluidic channel, the...

Embodiment 2

[0034] With the mass percent concentration of 60% regenerated silk fibroin aqueous solution as the spinning solution, the spinning solution was injected into the microfluidic chip at a flow rate of 10 μL / min under the temperature condition of 20 ° C, and the microfluidic channel outlet of the microfluidic chip After extrusion, the dry spinning process is used to solidify into filaments in the air and wind up on the roll; the air gap from the spinneret to the roll is 5 cm, and the winding speed is 5 cm / s.

[0035]The microfluidic chip includes a substrate and a diaphragm, the diaphragm has a groove, and the surface of the diaphragm with the groove is bonded to the substrate to form a microfluidic channel; the depth c of the whole process of the microfluidic channel is equal to 500 μm, the microfluidic channel width b gradually and continuously decreases from the inlet to the outlet, the inlet width is 1 mm, and the outlet width is 500 μm. Described microfluidic channel, the tra...

Embodiment 3

[0037] With the mass percent concentration of 45% regenerated silk fibroin aqueous solution as the spinning solution, the spinning solution was injected into the microfluidic chip at a flow rate of 5 μL / min at a temperature of 10 ° C, and the outlet of the microfluidic channel of the microfluidic chip After extrusion, the dry spinning process is used to solidify into filaments in the air and wind up on the roll; the air gap from the spinneret to the roll is 10 cm, and the winding speed is 3 cm / s.

[0038] The microfluidic chip includes a substrate and a diaphragm, the diaphragm has a groove, and the surface of the diaphragm with the groove is bonded to the substrate to form a microfluidic channel; the depth c of the whole process of the microfluidic channel is equal to 100 μm, the width b of the microfluidic channel gradually and continuously decreases from the inlet to the outlet, such as figure 1 and 2 As shown, the entrance width is 500 μm and the exit width is 250 μm. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com