Steel for anticorrosion sucker rods in oil field and production method thereof

A production method and sucker rod technology, which is applied in the direction of drill pipe, earthwork drilling, drilling equipment, etc., can solve the problems of high content, high production cost and high alloy cost, reduce production cost and alloy cost, and improve fatigue crack resistance Effects of Emerging and Expanding Capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

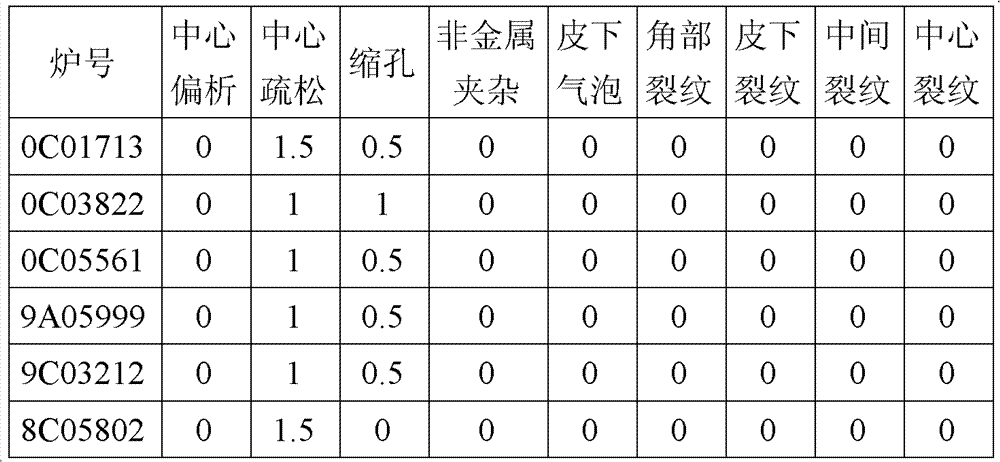

[0033] All indicators of the KD and H grade sucker rod steels in the present invention and the products produced by the technology in the present invention fully meet GB / T26075-2010. The quality of the sucker rod manufactured by using the product of the present invention has reached the international advanced level, and has been exported to the United States in batches.

[0034] The physical quality of the product, specific examples are as follows:

[0035] Table 1 Low magnification mass of cast slab

[0036]

[0037] Table 2 Sucker Rod Round Steel Chemical Composition Example (weight)%

[0038]

C

Si

mn

P

S

Ni

Cr

Mo

X012D30253

0.24

0.22

0.75

0.015

0.015

0.79

0.50

0.026

X012D30345

0.24

0.23

0.73

0.016

0.017

0.76

0.51

0.027

X012D30350

0.24

0.25

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com