Micro LHP radiating system for integrated electrofluid power pump

A technology integrating current and heat dissipation systems, applied in the field of micro LHP systems, can solve the problems of difficult to achieve high heat flux density heat dissipation, the working medium cannot be directional and stable circulation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

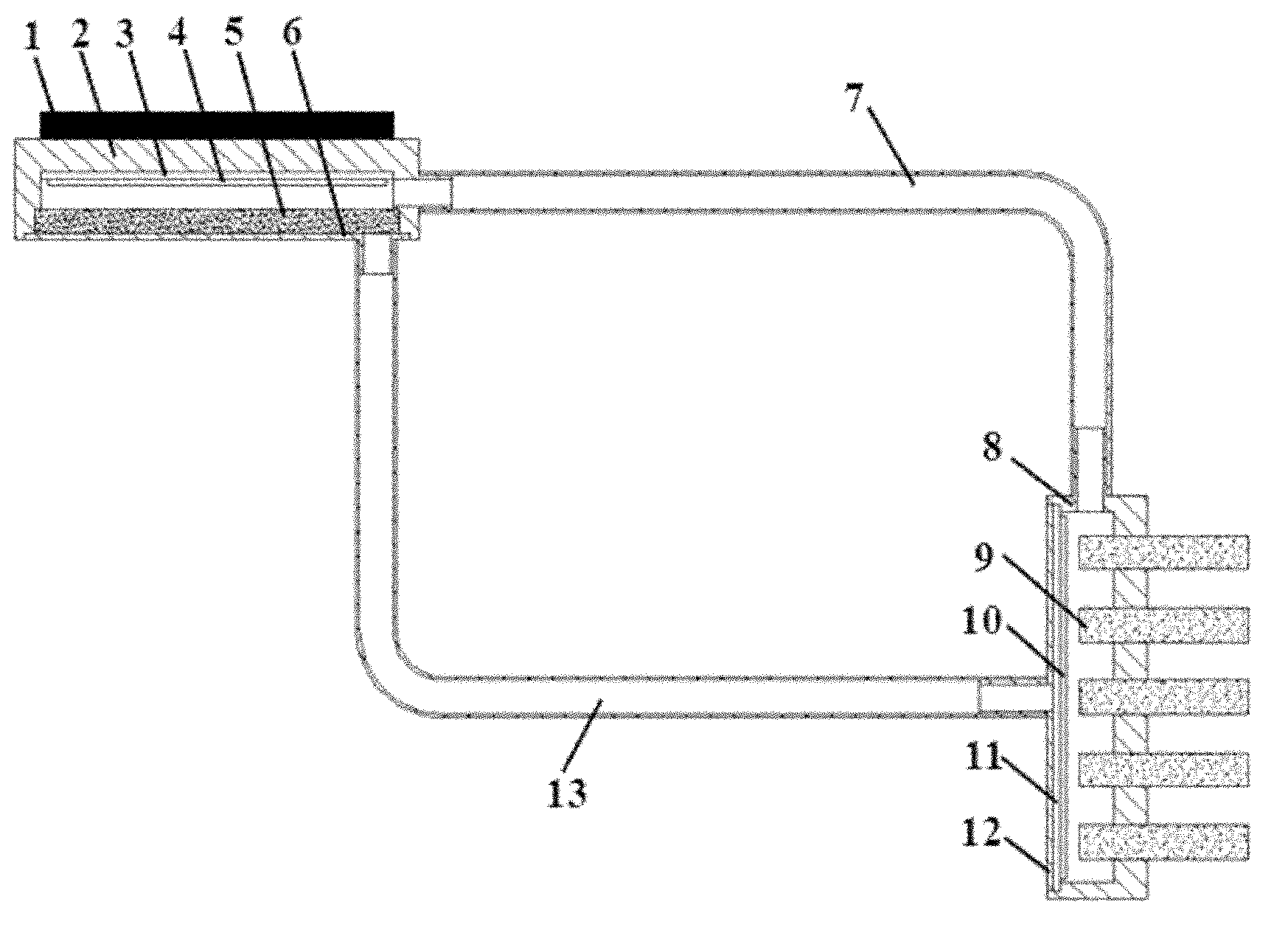

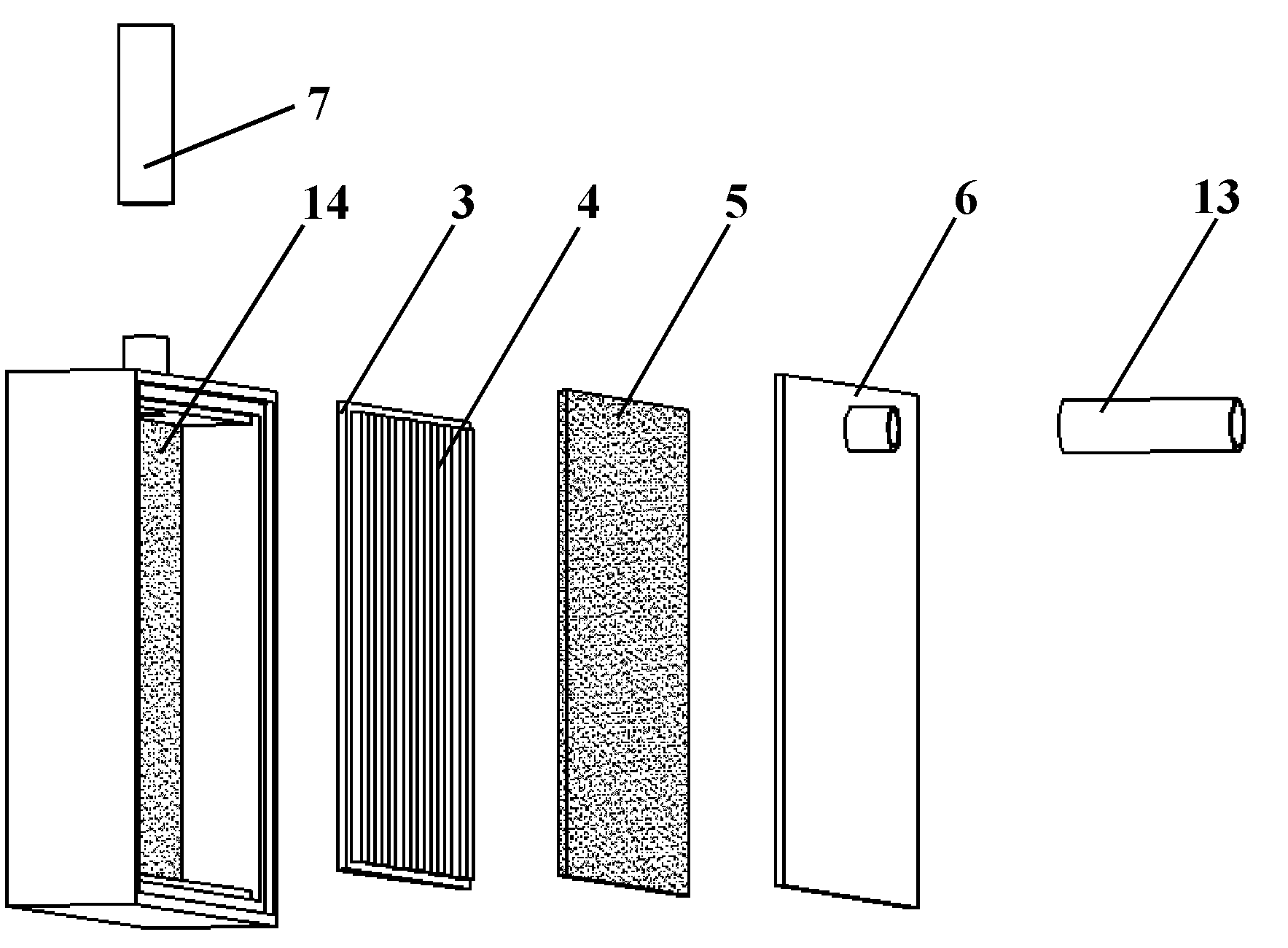

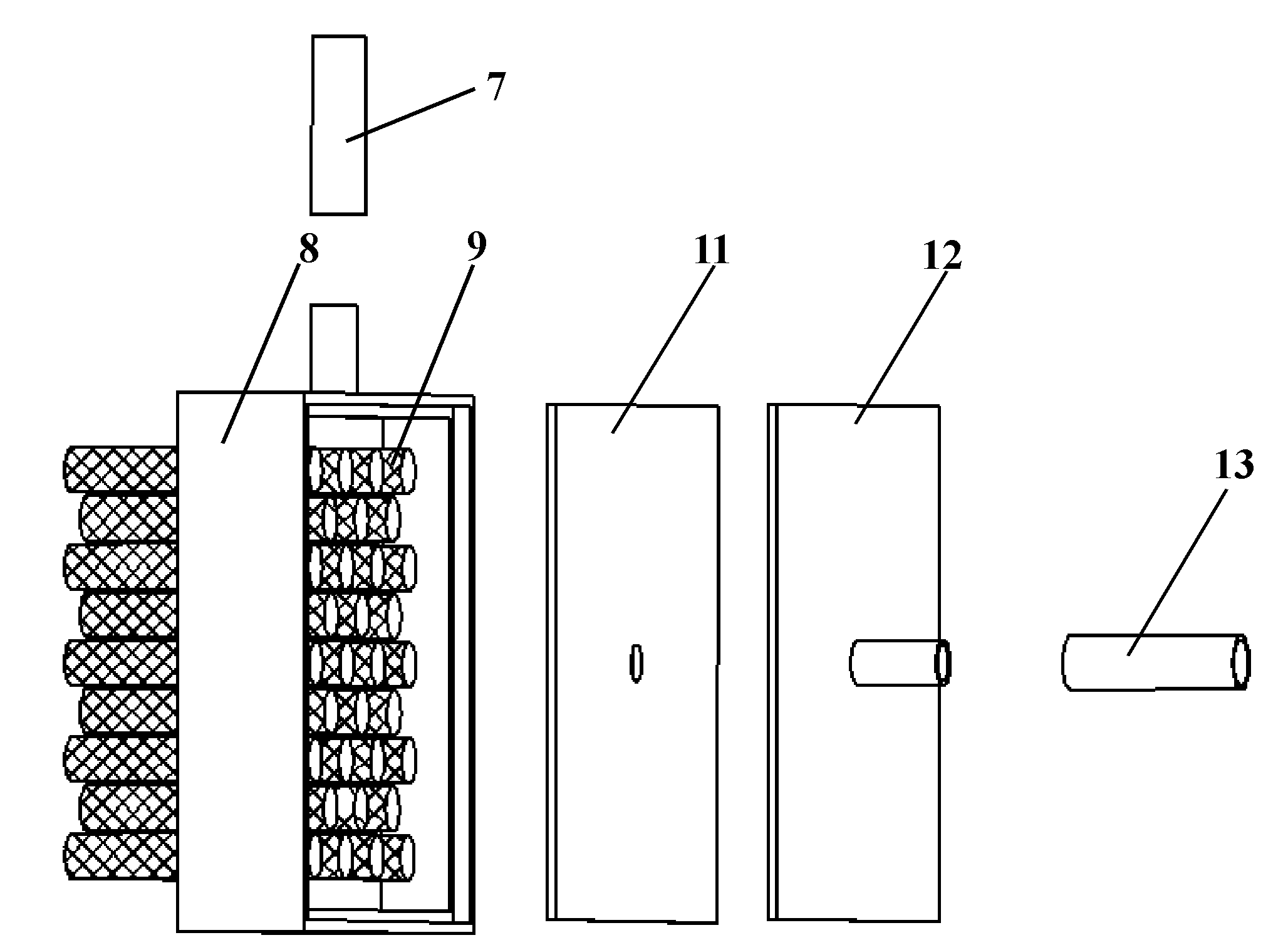

[0029] Such as figure 1 As shown, the miniature LHP heat dissipation system of the integrated electrohydrodynamic pump of the present invention includes an EHD evaporator 2 and an EHD condenser 8, and the EHD evaporator 2 and the EHD condenser 8 are connected through a steam pipeline 7 and a liquid pipeline 13; The EHD evaporator 2 is sequentially provided with a cover plate 6 with a liquid pipe interface, a capillary core 5, a high-voltage electrode 4, and an insulating partition 3, and the high-voltage electrode 4 and the insulating partition 3 are attached to each other and placed in the evaporator 2 The evaporating surface 14 (see figure 2 ), the capillary core 5 is attached to the inner surface of the cover plate 6; the capillary core 5 can be a porous metal sintered plate; the cover plate 6 is sealed with the EHD evaporator 2; the EHD condenser 8 is provided with A cover plate 12 with a liquid pipeline 13 interface, an insulating partition plate 11 with holes, a high-v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com