Method for preventing surface of Ti-IF steel from forming crack defects

A technology of surface forming and defects, applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., to achieve the effect of great economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

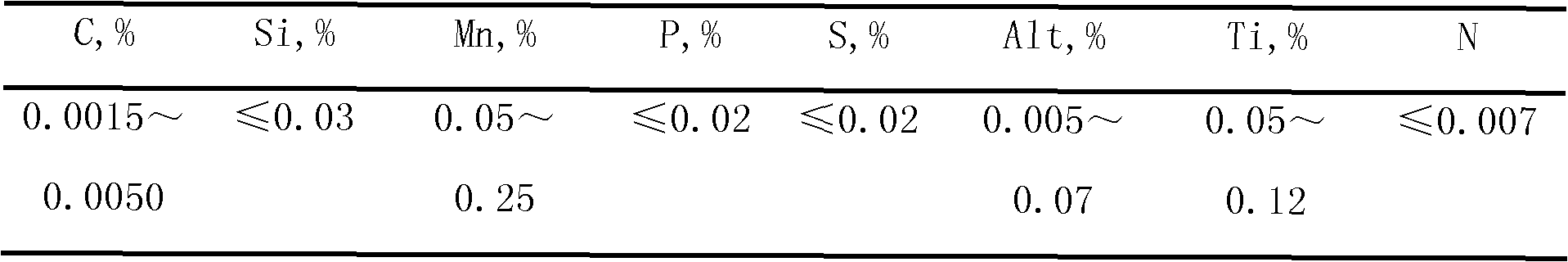

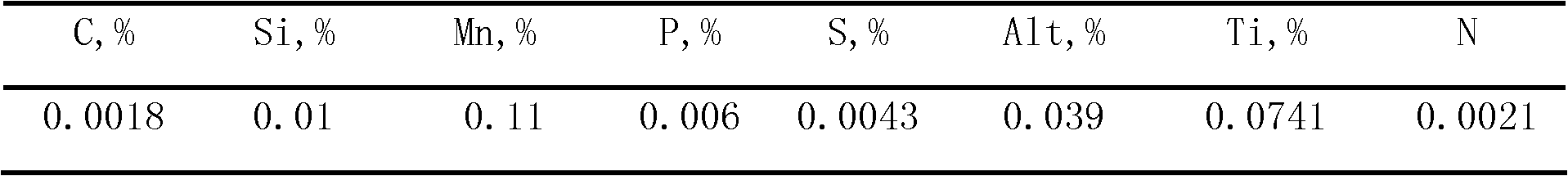

[0012] Embodiment 1, control chemical composition is as shown in table 2:

[0013] Table 2 embodiment 1 molten steel chemical composition

[0014]

[0015] The slab heating temperature is 1260°C, the final rolling temperature is 913°C, after rolling, it is cooled to 659°C for coiling, the reduction rate of acid rolling is 80%, the annealing temperature is 830°C, and the surface of the finished product has no forming grain defects after stamping.

Embodiment 2

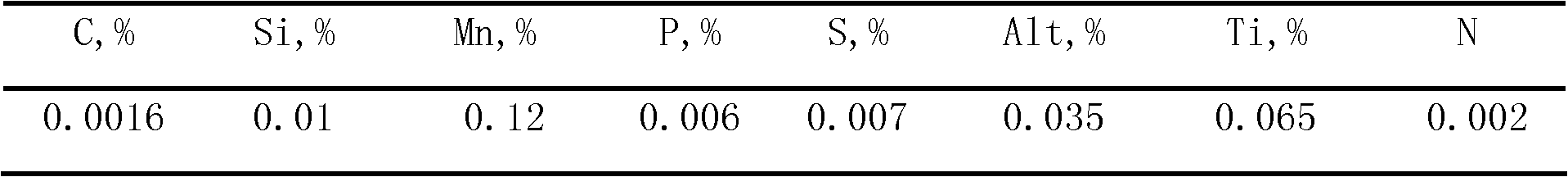

[0016] Embodiment 2, control chemical composition is as shown in table 3:

[0017] Table 3 embodiment 2 molten steel chemical composition

[0018]

[0019] The slab heating temperature is 1250°C, the final rolling temperature is 915°C, after rolling, it is cooled to 680°C for coiling, the reduction rate of acid rolling is 80%, the annealing temperature is 800°C, and the surface of the finished product has no forming grain defects after stamping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com