Method for preparing Al-Fe-V-Si heat-resistance aluminum alloy parts by using electron beam selective melting technology

An al-fe-v-si, selective melting technology, applied in additive manufacturing, process efficiency improvement, additive processing, etc., can solve the limitation of the wide application of Al-Fe-V-Si heat-resistant aluminum alloy The growth of matrix grains and the reduction of mechanical properties of alloys can achieve the effect of good protection effect, high material utilization rate and reduction of development cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

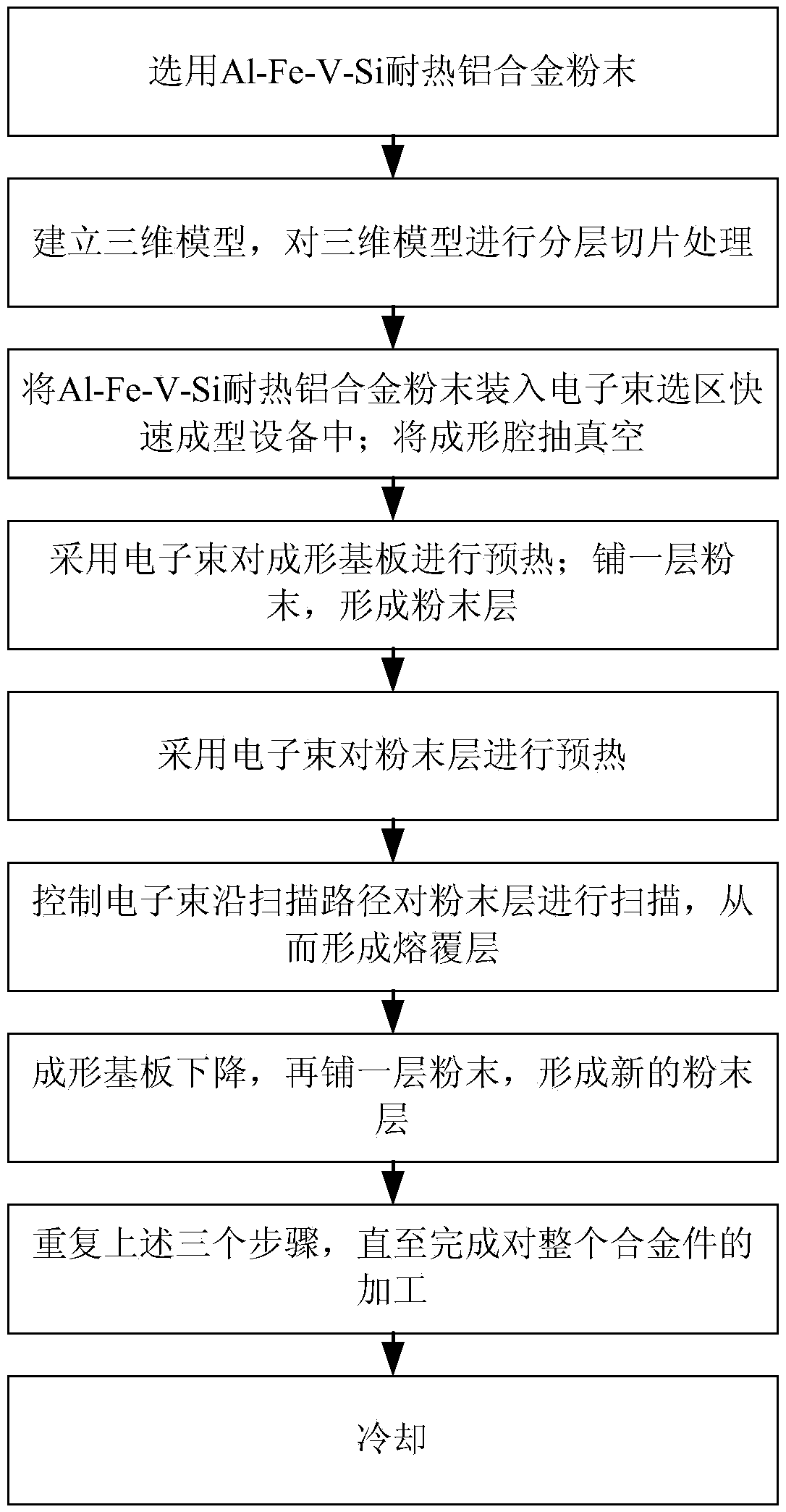

[0060] In this embodiment, the A2XX type electron beam selective melting system of Arcam AB, Sweden is used to prepare Al-11.5Fe-1.4V-2.3Si (wt.%, weight percentage) heat-resistant aluminum alloy parts. The preparation process is like figure 1 Shown, including:

[0061] (1). Select Al–11.5Fe–1.4V–2.3Si pre-alloyed powder prepared by argon atomization method, the powder is spherical or nearly spherical, and the diameter is between 45-160μm;

[0062] (2). First use the 3D drawing software (Magics) to establish the 3D CAD model of the alloy parts and save it as an STL file; then use the layering software (EBM assembler) to slice the STL file in the height direction and divide it into Slices with uniform thickness (0.1mm), slices contain cross-sectional profile information of alloy samples; use layering software to save slices as ABF files and import them into electron beam selective rapid prototyping equipment (EBM);

[0063] (3). Load the Al–11.5Fe–1.4V–2.3Si pre-alloy powder into the...

Embodiment 2

[0074] In this embodiment, the A2XX type electron beam selective melting system of Arcam AB, Sweden is used to prepare Al-11.5Fe-1.4V-2.3Si (wt.%, weight percentage) heat-resistant aluminum alloy parts. The preparation process is like figure 1 Shown, including:

[0075] (1). Select Al–11.5Fe–1.4V–2.3Si pre-alloyed powder prepared by argon atomization method, the powder is spherical or nearly spherical, and the diameter is between 45-160μm;

[0076] (2). First use the 3D drawing software (Magics) to establish the 3D CAD model of the alloy parts and save it as an STL file; then use the layering software (EBM assembler) to slice the STL file in the height direction and divide it into Slices with uniform thickness (0.05mm), slices contain cross-sectional profile information of alloy samples; use layering software to save slices as ABF files, and import them into electron beam selective rapid prototyping equipment (EBM);

[0077] (3). Put the Al–11.5Fe–1.4V–2.3Si pre-alloy powder into th...

Embodiment 3

[0088] In this embodiment, the A2XX type electron beam selective melting system of Arcam AB, Sweden is used to prepare Al-11.5Fe-1.4V-2.3Si (wt.%, weight percentage) heat-resistant aluminum alloy parts. The preparation process is like figure 1 Shown, including:

[0089] (1). Select Al–11.5Fe–1.4V–2.3Si pre-alloyed powder prepared by argon atomization method, the powder is spherical or nearly spherical, and the diameter is between 45-160μm;

[0090] (2). First use the 3D drawing software (Magics) to establish the 3D CAD model of the alloy parts and save it as an STL file; then use the layering software (EBM assembler) to slice the STL file in the height direction and divide it into Slices with uniform thickness (0.15mm), the slices contain the cross-sectional profile information of the alloy samples; the slices are saved as ABF files using layering software and imported into the electron beam selective rapid prototyping equipment (EBM);

[0091] (3). Load the Al–11.5Fe–1.4V–2.3Si pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com