Seal wax composition for train end connector of motor train unit and preparation method thereof

A technology for connectors and sealing wax, which is applied in the field of sealing wax composition and its preparation of EMU car end connectors, can solve the problems of no structural strength, insufficient adhesive force, and inability to cure, and achieve convenient construction and good initial adhesion Good, strong thixotropic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

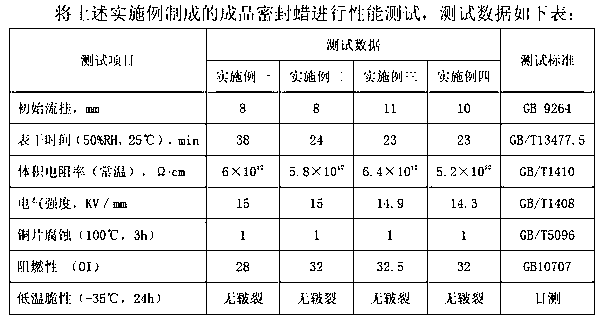

Examples

Embodiment 1

[0042] Example 1: Put 70 parts of polyethylene wax and 6 parts of polyisobutylene into a wax tank and heat to 140°C, stir until they are all melted, then put them into a blender, cool down to room temperature, and set aside; put hydroxyl-terminated polydiorganosilicon Add 10 parts of oxane polymer and 12 parts of aluminum hydroxide flame retardant into the kneader and knead for 30 to 120 minutes. After cooling to room temperature, add them into the mixer; Parts were added into the blender and stirred together, the vacuum degree of the blender was controlled to 0.06MPa, and the stirring time was 2.5 hours to obtain the finished product.

Embodiment 2

[0043] Example 2: Put 65 parts of polyethylene wax and 3 parts of polyisobutylene into a wax tank and heat to 140°C, stir until they are completely melted, then put them into a blender, cool down to room temperature, and set aside; the hydroxyl-terminated polydiorganosilicon Add 12 parts of oxane polymer and 18 parts of aluminum hydroxide flame retardant into the kneader and knead for 30-120 minutes, cool to room temperature and add to the mixer; then add 1.5 parts of vinyltrimethoxysilane, 0.5 Add portions to blender and blend together. The vacuum degree of the mixer is controlled to 0.06 MPa, and the stirring time is 2.5 hours to obtain the finished product.

Embodiment 3

[0044] Example 3: Put 63 parts of polyethylene wax and 2 parts of polyisobutylene into a wax tank and heat to 140°C, stir until they are all melted, then put them into a blender, cool down to room temperature, and set aside; put hydroxyl-terminated polydiorganosilicon Add 12 parts of oxane polymer and 20 parts of magnesium hydroxide flame retardant into the kneader and knead for 30-120 minutes, cool to room temperature and add into the mixer; then add 2 parts of vinyltrimethoxysilane, 1 part of titanate Add portions to blender and blend together. The vacuum degree of the mixer is controlled to 0.06 MPa, and the stirring time is 2.5 hours to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com