Single-component water-soluble environmentally-friendly roller adhesive and preparation method thereof

A water-soluble, one-component technology, applied in the directions of adhesives, adhesive types, rosin adhesives, etc., it can solve the problems of easy skinning and granulation at the edge of spraying, uneven thickness of artificial spraying, and affecting the process. , to achieve the effect of fast drying, labor saving and good initial viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

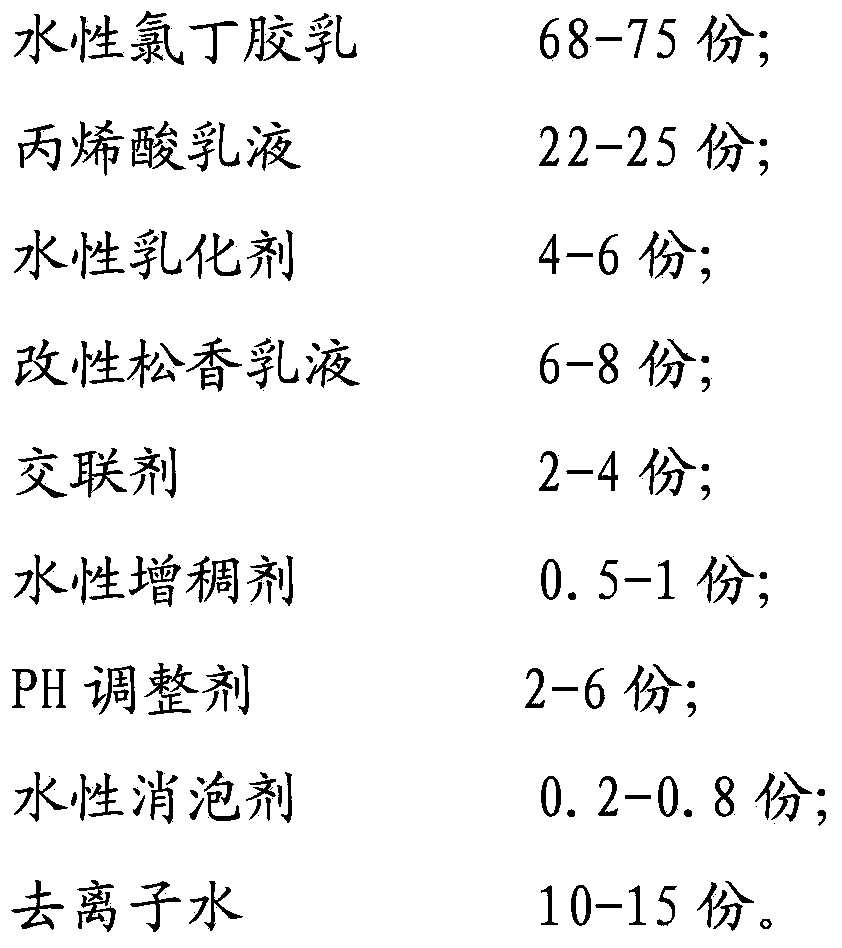

[0033] A kind of one-component water-soluble environment-friendly roller rubber, comprises components and the parts by weight of each component as follows:

[0034] 60 parts of water-based neoprene latex;

[0035] Acrylic emulsion 30 parts;

[0036] 8 parts of water-based emulsifier;

[0037] 10 parts of modified rosin emulsion;

[0038] 1 part of crosslinking agent;

[0039] 0.5 parts of water-based thickener;

[0040] 6 parts of pH adjuster;

[0041] 0.8 parts of water-based defoamer;

[0042] 20 parts of deionized water.

[0043] Both the acrylic emulsion and the modified rosin emulsion particles are ionized emulsions, and the particle diameters of the emulsions are both less than 0.5 microns.

[0044] The preparation method of described one-component water-soluble environmental protection roller rubber, comprises the following steps:

[0045] Step a: weighing water-based neoprene latex, acrylic acid emulsion, water-based emulsifier, modified rosin emulsion, crossli...

Embodiment 2

[0048] A kind of one-component water-soluble environment-friendly roller rubber, comprises components and the parts by weight of each component as follows:

[0049] 70 parts of water-based neoprene latex;

[0050] Acrylic emulsion 25 parts;

[0051] 2 parts of water-based emulsifier;

[0052] 8 parts of modified rosin emulsion;

[0053] 3 parts of cross-linking agent;

[0054] 0.6 parts of water-based thickener;

[0055] 2 parts of pH adjuster;

[0056] 0.6 parts of water-based defoamer;

[0057] 10 parts of deionized water.

[0058] Both the acrylic emulsion and the modified rosin emulsion particles are ionized emulsions, and the emulsion particle diameters are both equal to 0.5 micron.

[0059] The preparation method of described one-component water-soluble environmental protection roller rubber, comprises the following steps:

[0060] Step a: weighing water-based neoprene latex, acrylic acid emulsion, water-based emulsifier, modified rosin emulsion, crosslinking age...

Embodiment 3

[0063] A kind of one-component water-soluble environment-friendly roller rubber, comprises components and the parts by weight of each component as follows:

[0064] 80 parts of water-based neoprene latex;

[0065] Acrylic emulsion 20 parts;

[0066] 10 parts of water-based emulsifier;

[0067]5 parts of modified rosin emulsion;

[0068] 5 parts of cross-linking agent;

[0069] 1 part water-based thickener;

[0070] 8 parts of PH regulator;

[0071] 0.2 parts of water-based defoamer;

[0072] 15 parts of deionized water.

[0073] Both the acrylic emulsion and the modified rosin emulsion particles are ionized emulsions, and the emulsion particle diameters are both equal to 0.5 micron.

[0074] The preparation method of described one-component water-soluble environmental protection roller rubber, comprises the following steps:

[0075] Step a: Weighing water-based neoprene latex, acrylic acid emulsion, water-based emulsifier, modified rosin emulsion, crosslinking agent, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com