Preparation method of polyaniline/carbon nano tube compound electromagnetic shielding material

A technology of carbon nanotube composite and electromagnetic shielding materials, which is applied in the field of preparation of polyaniline/carbon nanotube composite electromagnetic shielding materials, can solve the problems of affecting electromagnetic shielding performance and uneven carboxylation of carbon nanotubes, and achieves an increase in total Shielding effectiveness value, good electromagnetic wave shielding performance, effect of improving electromagnetic wave shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

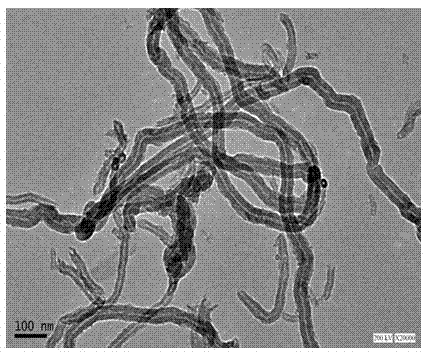

[0019] (a) Carboxylation of carbon nanotubes: 0.5 g of carbon nanotubes and 0.5 g of NaNO 3 Put them into 250ml three-neck flasks respectively, slowly add 20ml of concentrated H at 0°C and magnetic stirring 2 SO 4 , after stirring for 15min, slowly add 3.0g KMnO in 35°C water bath 4 , continue to stir for 2h; then slowly add 40ml of water, and stir for another 1h in a 90°C water bath; finally add 100ml of water and 3ml of 30% H 2 o 2 After mixing evenly, cool to room temperature; centrifuge washing with distilled water until neutral, and dry in a vacuum oven at 60°C to obtain carboxylated carbon nanotubes, such as figure 1 TEM images of carboxylated carbon nanotubes shown;

[0020] (b) Add 0.1 g of carboxylated carbon nanotubes to 40 ml of hydrochloric acid solution, and ultrasonically disperse for 1 hour; then add 0.32 g of aniline monomer into the hydrochloric acid solution, and ultrasonically disperse for 2 hours; then take 0.75 g of ammonium persulfate Dissolve in 20 ...

Embodiment 2

[0023] (a) Carboxylation of carbon nanotubes: 0.5 g of carbon nanotubes and 1.0 g of NaNO 3 Put them into 250ml three-necked flasks respectively, slowly add 30ml of concentrated H at 0°C and magnetic stirring 2 SO 4 , after stirring for 15min, slowly add 3.5g KMnO in 30°C water bath 4 , continue to stir for 2h; then slowly add 40ml of water, and stir for another 1h in a 90°C water bath; finally add 100ml of water and 3ml of 30% H 2 o 2 After mixing evenly, cool to room temperature; centrifuge washing with distilled water until neutral, and dry in a vacuum oven at 60°C to obtain carboxylated carbon nanotubes;

[0024] (b) Take 0.1g of carboxylated carbon nanotubes and add them to 40ml of hydrochloric acid solution, ultrasonically disperse for 1 hour; then add 0.5g of aniline monomer into the hydrochloric acid solution, and ultrasonically disperse for 2 hours; then take 0.8g of ammonium persulfate Dissolve in 20 ml of hydrochloric acid solution, mix well and slowly add to th...

Embodiment 3

[0027] (a) Carboxylation of carbon nanotubes: 0.5 g of carbon nanotubes and 0.3 g of NaNO 3 Put them into 250ml three-necked flasks respectively, and slowly add 20ml of concentrated H at 5°C under magnetic stirring conditions. 2 SO 4 , after stirring for 15min, slowly add 2.0g KMnO in 40°C water bath 4 , continue to stir for 2h; then slowly add 40ml of water, and stir for another 1h in a 90°C water bath; finally add 100ml of water and 3ml of 30% H 2 o 2 After mixing evenly, cool to room temperature; centrifuge washing with distilled water until neutral, and dry in a vacuum oven at 60°C to obtain carboxylated carbon nanotubes;

[0028] (b) Take 0.1g of carboxylated carbon nanotubes and add them to 40ml of hydrochloric acid solution, ultrasonically disperse for 1 hour; then add 0.6g of aniline monomer into the hydrochloric acid solution, and ultrasonically disperse for 2 hours; then take 1g of ammonium persulfate to dissolve In 20 ml of hydrochloric acid solution, after mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com