Microwave synthesis method for sulfonic group modified polyaspartic acid

A technology of polyaspartic acid and microwave synthesis, which is applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc., which can solve unfavorable industrial production, long synthesis time, large energy consumption, etc. problems, to achieve excellent scale inhibition performance, fast synthesis speed, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

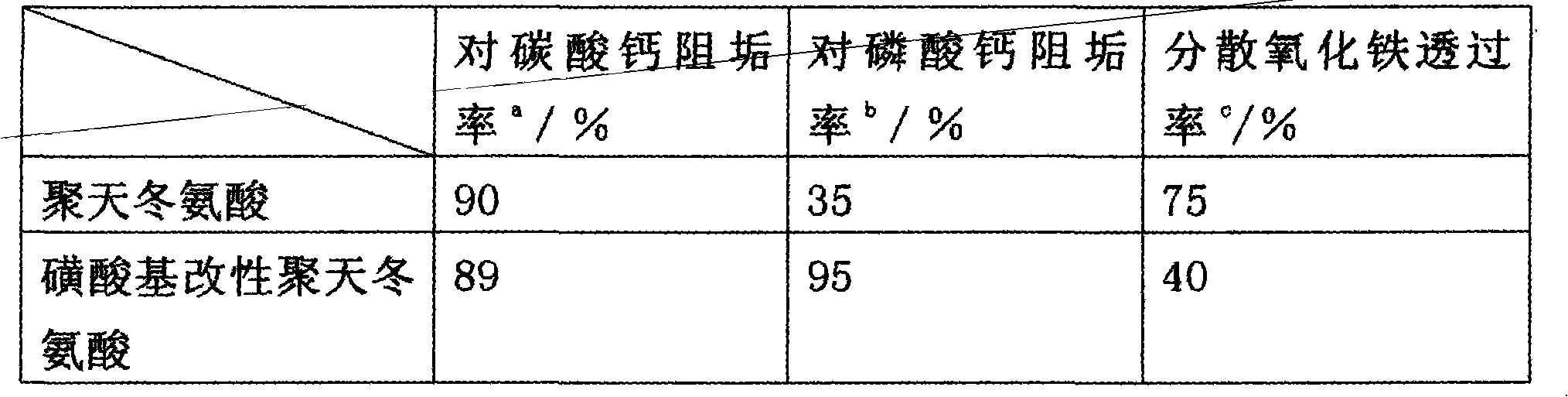

Image

Examples

Embodiment 1

[0019] Add 9.8 grams of maleic anhydride, 5.8 grams of ammonium carbonate, and 7.4 grams of sodium 2-aminoethanesulfonate into a beaker, mix well, add 20 mL of distilled water to make a paste, and irradiate for 5 minutes under the condition of microwave power 300W to obtain Brown-red fluffy solid substance. Add 25 mL of 2 mol / L NaOH solution to dissolve the above product, and irradiate it under 300W microwave conditions for 3 minutes to obtain a reddish-brown viscous sulfonic acid group-modified polyaspartic acid solution. Use hydrochloric acid with a concentration of 35% to 37% to adjust the pH of the above solution to 2 to 3, add this solution dropwise to 300mL of vigorously stirred anhydrous ethanol to obtain a brownish yellow precipitate, filter the precipitate under reduced pressure, and store at 60°C, Drying under a vacuum condition of 0.002 MPa gave 14.2 grams of sulfonic acid group-modified polyaspartic acid product, with a total yield of 94%.

Embodiment 2

[0021] Add 9.8 grams of maleic anhydride, 10 mL of distilled water, 6.7 grams of sodium sulfamate and 7.3 grams of 28% ammonia water in a beaker, and irradiate for 4 minutes under the condition of a microwave power of 400W to obtain a brownish red fluffy solid substance . Add 25 mL of 2 mol / L NaOH solution to dissolve the above product, and irradiate it under 300W microwave conditions for 3 minutes to obtain a reddish-brown viscous sulfonic acid group-modified polyaspartic acid aqueous solution. Use hydrochloric acid with a concentration of 35% to 37% to adjust the pH of the above solution to 2 to 3, add this solution dropwise to 300mL of vigorously stirred anhydrous ethanol to obtain a brownish yellow precipitate, filter the precipitate under reduced pressure, and store at 60°C, Drying under a vacuum condition of 0.002 MPa gave 13.3 grams of sulfonic acid group-modified polyaspartic acid product, with a total yield of 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com