Reactor for treating VOCs by plasma cooperating chemical catalysis

A technology of chemical catalysis and plasma, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve the problems of low selectivity and high energy consumption, and achieve increased residence time, improved degradation efficiency, and improved energy utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

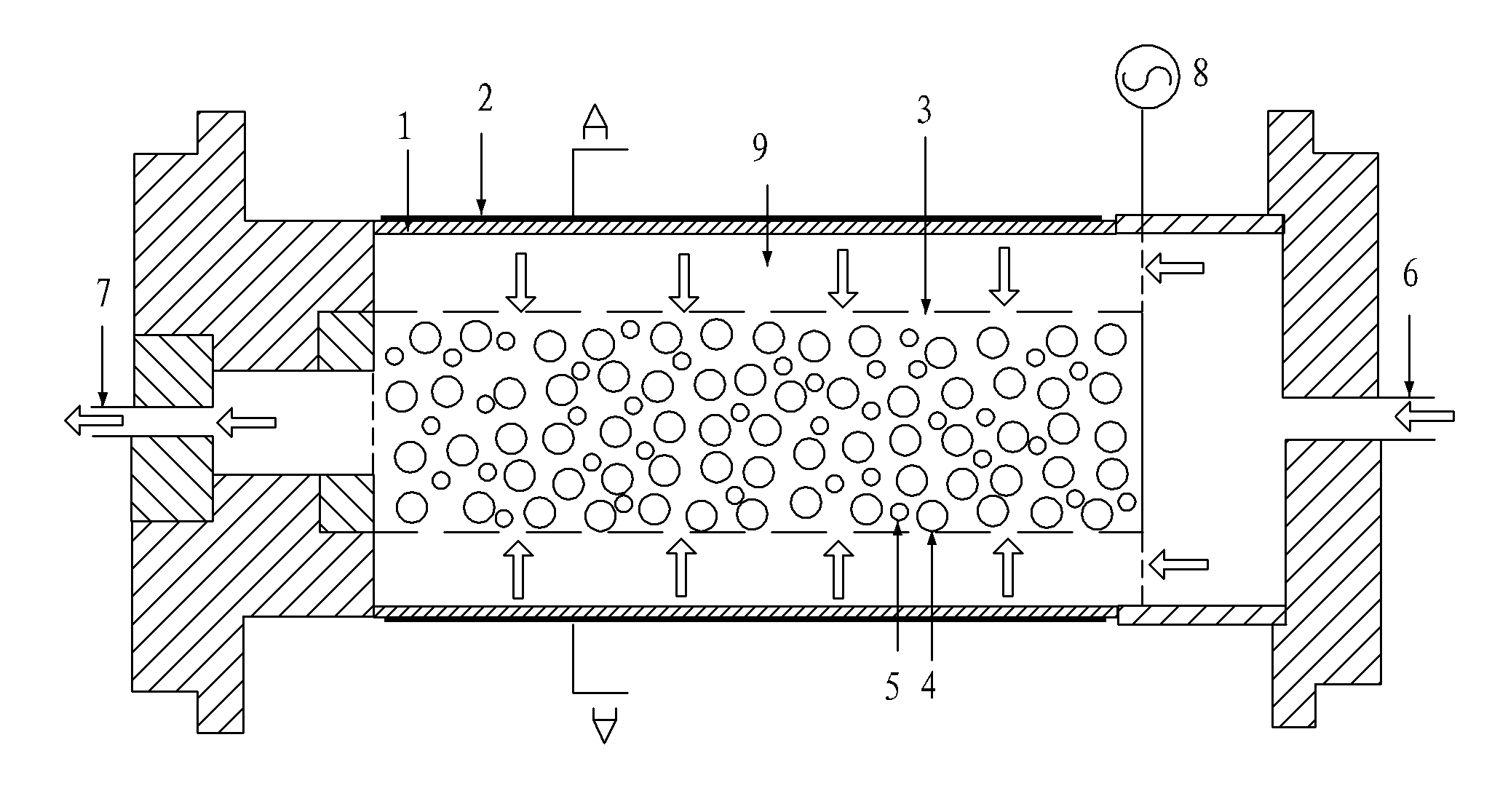

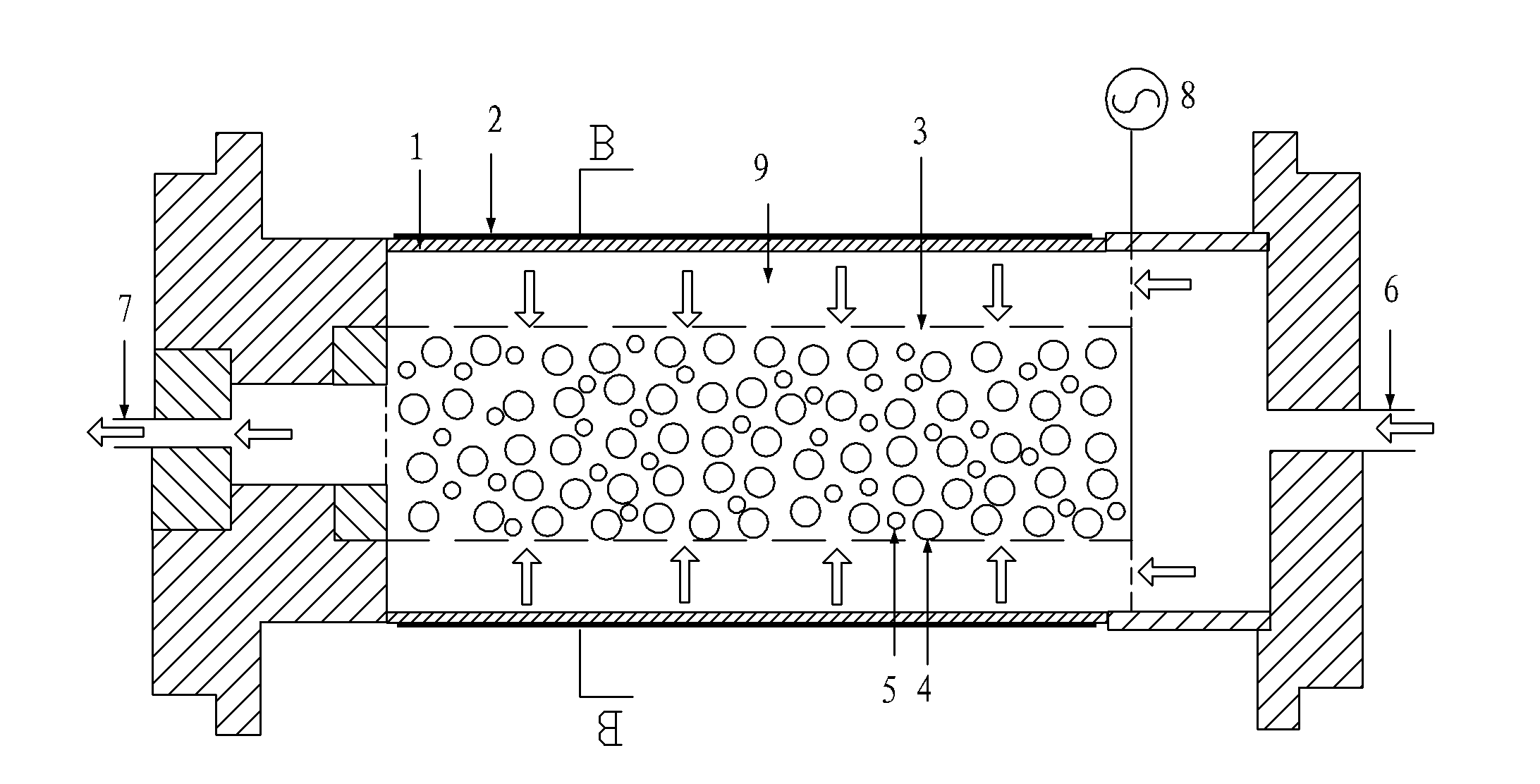

[0028] Such as figure 1 and figure 2 A plate-type plasma synergistic chemical catalysis reactor for treating VOCs waste gas is shown, including a quartz glass shell 1, one end of the shell 1 is an air inlet 6, and the other end is an air outlet 7; the outer layer of the shell 1 is wrapped The metal conductor 2, the metal conductor 2 is grounded as the outer electrode of the dielectric barrier discharge; there is a stainless steel reaction chamber 3 inside the housing 1, and the reaction chamber 3 is connected to the AC high-voltage power supply 8 as the inner electrode of the dielectric barrier discharge. The cross-sections of the housing 1 and the reaction chamber 3 are both rectangular, and one opposite wall of the reaction chamber 3 is close to the inner wall of the housing 1 and is isolated with an insulating material; the other opposite wall has a small hole with a diameter of less than 3mm. The opening ratio is 30-50%, and there is a discharge air gap 9 between the inn...

Embodiment 2

[0034] a kind of like image 3 and Figure 4 The cylinder-type reactor for cooperating chemical and catalytic treatment of VOCs with plasma includes a shell 1 (outer cylinder) with a circular cross section and a reaction chamber 3 (inner cylinder). The outer cylinder is a quartz glass tube, the outer wall of the quartz glass tube is covered with a metal conductor 2, and the metal conductor 4 is grounded as an external electrode for dielectric barrier discharge. The metal conductor 4 is silver foil or silver coating with a thickness of 0.5-1 mm. The inner cylinder is a stainless steel cylinder. The opening in the inner cylinder is used as a gas channel, and it is connected to an AC high-voltage power supply 8 as an inner electrode for dielectric barrier discharge. The opening diameter of the inner cylinder wall can be selected according to the particle size of the adsorbent 4 and the catalyst 5, which is smaller than the particle diameter of the adsorbent 4 and the catalyst ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com