Method for preparing high-purity rice protein and acquired products by using same

A rice protein, high-purity technology, applied in the field of high-purity rice protein, high-purity rice protein preparation, can solve problems such as low protein extraction rate, reduced solubility, and protein denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

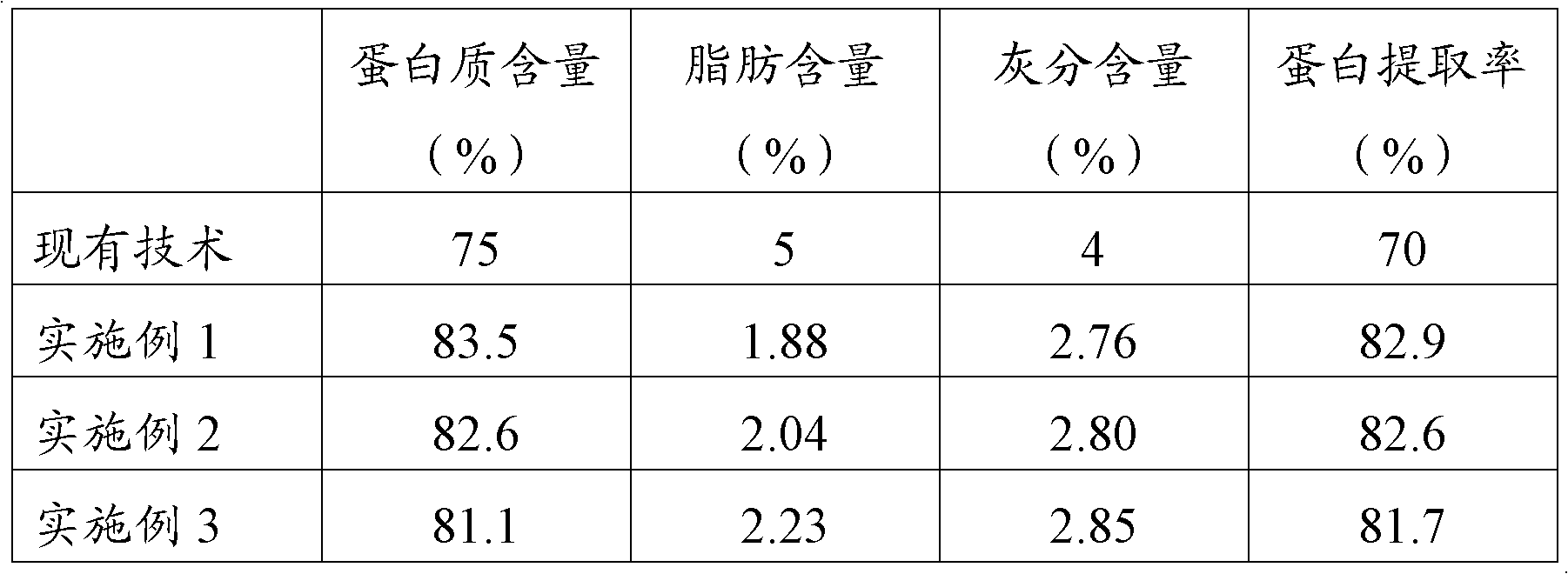

Examples

Embodiment 1

[0081] Example 1: The present invention prepares the method for high-purity rice protein

[0082] The steps of this method are as follows:

[0083] (1) pulping and refining

[0084] Add 5.25 kg of water to 1 kg of rice dregs with a protein weight percentage of 41.3%, to obtain 16% rice milk by weight of rice dregs, grind the rice milk with a colloid mill, and then filter through a 200-mesh sieve to obtain a filtrate.

[0085] (2) Degreasing

[0086] The filtrate obtained in step (1) was heated to 65°C, and then 40% weight concentration of sodium hydroxide aqueous solution was added to adjust the pH value of the filtrate to 8.2, and then soaked at 63°C for 30 minutes to saponify fat and swell protein.

[0087] (3) Enzymolysis reaction

[0088] The solution of step (2) was incubated at 63° C. for 30 minutes, adjusted its pH value to 4.2 with 1 mol / L hydrochloric acid solution, and then added 0.2% glucoamylase based on the mass of rice dregs. The enzyme activity of the gluco...

Embodiment 2

[0096] Example 2: The present invention prepares the method for high-purity rice protein

[0097] The steps of this method are as follows:

[0098] (1) pulping and refining

[0099]Add 5.06 kg of water to 1 kg of rice dregs with a protein weight percentage of 42.0%, to obtain rice milk of 16.5% by weight of rice dregs, grind the rice milk with a colloid mill, and then filter through a 150-mesh sieve to obtain a filtrate.

[0100] (2) Degreasing

[0101] The filtrate obtained in step (1) was heated to 64°C, and then 45% aqueous sodium hydroxide solution was added to adjust the pH value of the filtrate to 8.3, and then soaked at 60°C for 30 minutes to saponify the fat and swell the protein.

[0102] (3) Enzymolysis reaction

[0103] The solution of step (2) was incubated at 60° C. for 40 minutes, adjusted its pH value to 4.3 with 1 mol / L hydrochloric acid solution, and then added 0.1% glucoamylase based on the mass of rice dregs. The enzyme activity of the glucoamylase was ...

Embodiment 3

[0111] Example 3: The present invention prepares the method for high-purity rice protein

[0112] The steps of this method are as follows:

[0113] (1) pulping and refining

[0114] Add 4.9 kg of water to 1 kg of rice dregs with a protein weight percentage of 40.7%, to obtain 17% rice milk by weight of rice dregs, grind the rice milk with a colloid mill, and then filter through a 250-mesh sieve to obtain a filtrate.

[0115] (2) Degreasing

[0116] The filtrate obtained in step (1) was heated to 63° C., and then 35% by weight aqueous sodium hydroxide solution was added to adjust the pH value of the filtrate to 8.5, and then soaked at 65° C. for 30 minutes to saponify fat and swell protein.

[0117] (3) Enzymolysis reaction

[0118] The solution of step (2) was incubated at 65° C. for 20 minutes, adjusted its pH value to 4.5 with 1 mol / L hydrochloric acid solution, and then added 0.3% glucoamylase based on the mass of rice dregs. The enzyme activity of the glucoamylase was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com