Process for producing optical-fiber base material

一种制造方法、光纤母材的技术,应用在制造工具、玻璃制造设备、玻璃纤维制品等方向,能够解决沟槽型耐弯单模光纤不具备OH基降低手段等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

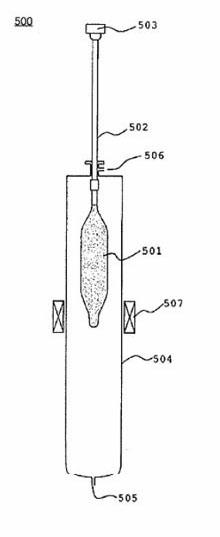

[0075] use figure 2 The illustrated glass base material manufacturing apparatus 400 synthesizes the porous glass base material for the initial base material by the VAD method. Next, put the porous glass base material for the initial base material into image 3 In the apparatus shown, the glass base material for the initial base material was synthesized by heating to 1100°C in a helium atmosphere containing 3% chlorine for dehydration, and then heating to 1520°C in a helium atmosphere for vitrification.

[0076] The obtained glass base material for the initial base material is composed of a core containing germanium and a first cladding portion not containing a dopant. The OH group content of the glass base material for the initial base material is extremely small, 0.15 ppb or less.

[0077] After being heated and drawn in an electric furnace in a nitrogen atmosphere, the surface is mechanically ground and polished to a thickness of about 0.5 mm to produce a core rod with an outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com