Method for manufacturing 980nm single-mode wavelength stabilized semiconductor laser

A semiconductor and laser technology, applied in the field of discrete mode semiconductor laser preparation, can solve the problems of highly sensitive collimated beam, complex lithography precision manufacturing process, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

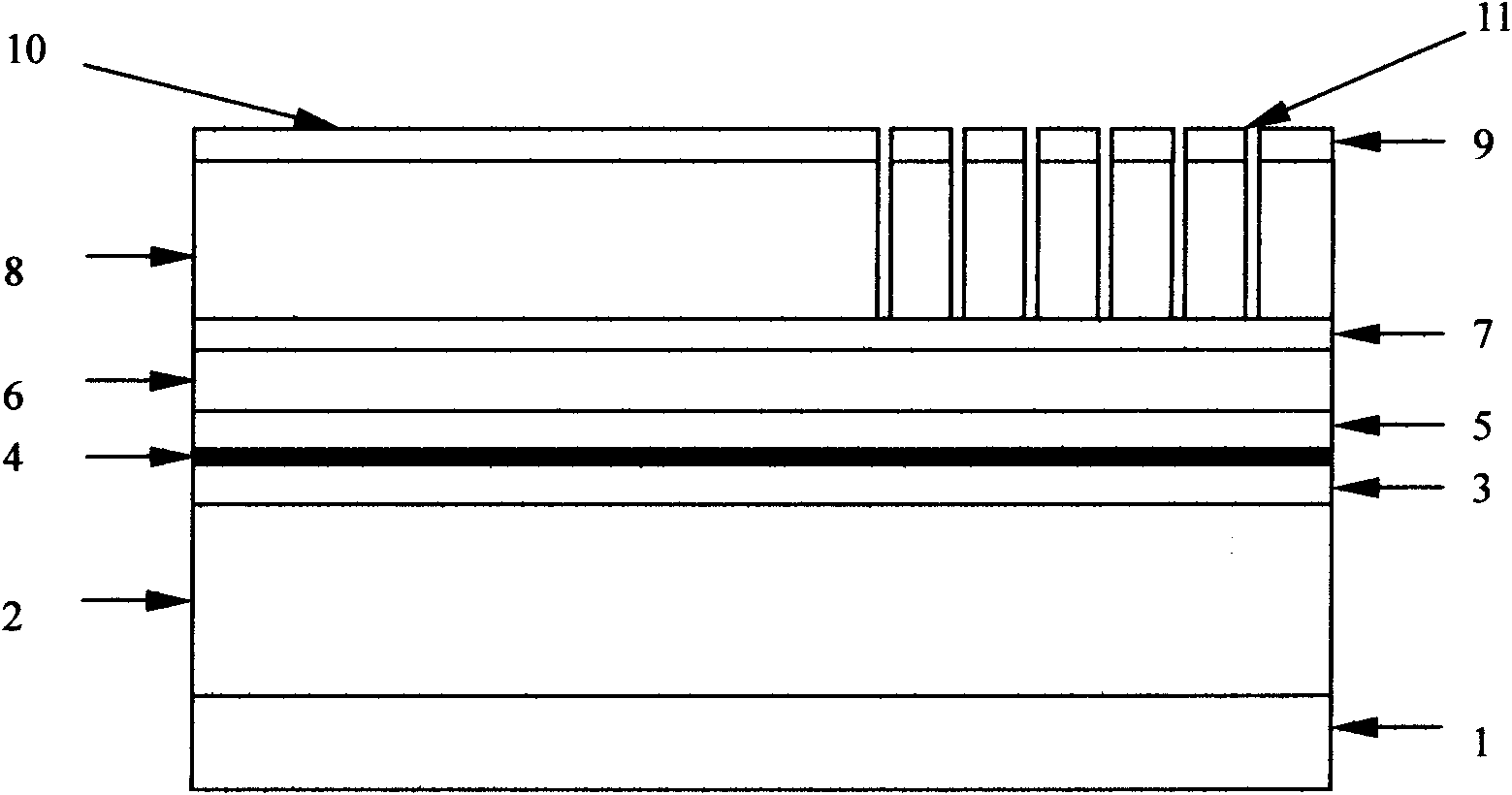

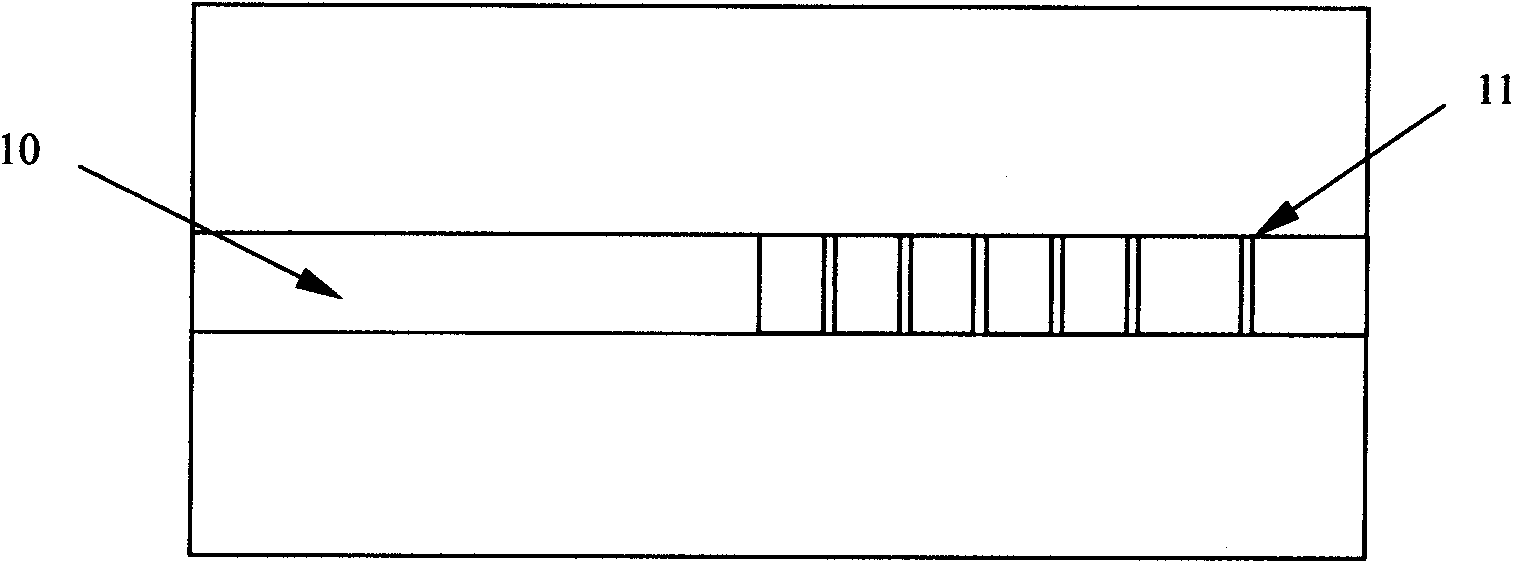

[0024] see figure 1 , figure 2 and image 3 , the invention provides a method for preparing a wavelength-stabilized 980nm single-mode laser, comprising the steps of:

[0025] Step 1: Take a GaAs substrate 1;

[0026] Step 2: Prepare N-type AlGaAs lower confinement layer 2, lower waveguide layer 3, quantum well layer 4, upper waveguide layer 5, first P-type upper confinement layer 6, etch cut-off layer on GaAs substrate 1 in sequence 7. The second P-type upper confinement layer 8 and P-type cap layer 9; wherein the lower confinement layer 2 is a highly doped N-type aluminum gallium arsenic material (Al 0.4 Ga 0.6 As), the Si doping concentration is 1×10 18 cm -3 , with a thickness of 1.5 μm, the purpose is to limit the diffusion of carriers in the active region, so as to reduce the threshold current and improve efficiency; the lower waveguide layer 3 is made of non-doped aluminum gallium arsenic material (A 0.2 Ga 0.8 As) with a thickness of 90nm, the purpose is to enh...

Embodiment

[0030] see again figure 1 , figure 2 and image 3 As shown, the present invention provides a method for preparing a wavelength-stabilized 980nm single-mode laser, comprising the steps of:

[0031] Step 1: Take a GaAs substrate 1;

[0032] Step 2: Prepare N-type AlGaAs lower confinement layer 2, lower waveguide layer 3, quantum well layer 4, upper waveguide layer 5, first P-type upper confinement layer 6, etch cut-off layer on GaAs substrate 1 in sequence 7. The second P-type upper confinement layer 8 and P-type cap layer 9; wherein the lower waveguide layer 3 is made of undoped AlGaAs material, wherein the quantum well layer 4 is made of undoped AlGaInAs material, wherein the upper The waveguide layer 5 is a non-doped AlGaAs material, wherein the first P-type upper confinement layer 6 is a highly doped AlGaAs material with a thickness of 0.3 μm, and the etching cut-off layer 7 is a highly doped P-type InGaP material with a thickness of 20nm, wherein the second P-type uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com