Tungstic oxide semiconductor battery and preparation method therefor

A technology of tungsten oxide and semiconductor, which is applied in the field of tungsten oxide semiconductor battery and its preparation, and can solve the problems of making batteries with tungsten oxide semiconductor materials that have not been seen yet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

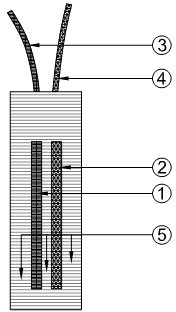

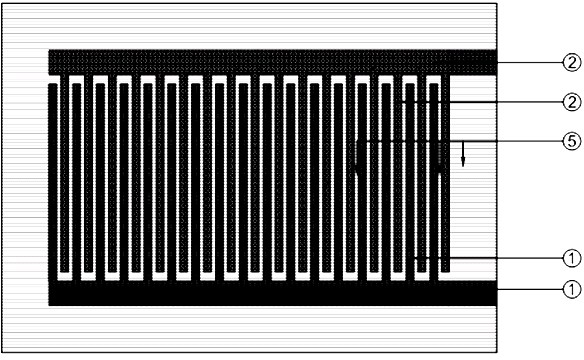

[0038] Example 1 Fabrication of a tungsten oxide semiconductor battery.

[0039] (1) Fabrication of planar electrodes. Cut the copper foil and zinc foil into metal strips with a width of 2mm and a length of 2cm, and paste them on the same horizontal plane on the surface of the plastic film with an adhesive or double-sided tape. The distance between the two electrodes is 2mm, and at the ends of the two electrodes Connect the lead wires separately, and then surround the electrode with an insulating plastic sheet about 2mm thick to form a 1.5cm long and 0.7mm wide, effective area of 1.05cm 2 slurry room.

[0040] (2) Preparation of tungsten oxide raw material. Prepare 100ml sodium tungstate reaction liquid according to the concentration ratio of sodium tungstate: acetic acid = 1: 0.2 moles, slowly add the sodium tungstate reaction liquid dropwise to 30ml of hydrochloric acid solution with a concentration of 2 moles per liter under magnetic stirring conditions, Gradually prod...

Embodiment 2

[0042] Example 2 Fabrication of a tungsten oxide semiconductor battery.

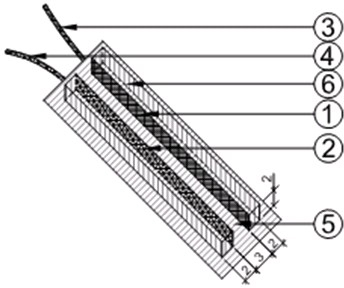

[0043] (1) Fabrication of three-dimensional electrode pairs. Cut the silver foil and the zinc foil into metal strips with a length of 4cm and a width of 2mm, respectively connect lead wires at the ends of the two metal strips, and paste the two metal strips on the surface of two 3mm thick insulating sheets with adhesive, and then It is oppositely pasted on the same horizontal surface of the plastic film, the distance between the two electrodes is 3mm, and an insulating sheet with a length of 4mm and a width of 3mm is added between the two electrodes to form a width of 3mm and a length between the two electrodes. 3.2cm effective area is 0.96cm 2 slurry room.

[0044] (2) Preparation of tungsten oxide raw material. Prepare 200ml sodium tungstate reaction solution according to the concentration ratio of sodium tungstate: citric acid = 1:0.3 moles, slowly add the sodium tungstate reaction solution dropwis...

Embodiment 3

[0046] Example 3 Fabrication of a tungsten oxide semiconductor battery.

[0047] (1) Fabrication of planar electrodes. Cut the copper foil and zinc foil into metal strips with a width of 2mm and a length of 3cm, and paste them on the same horizontal surface of the plastic film with adhesive or double-sided tape. The distance between the two electrodes is 2mm, and the ends of the two electrodes are respectively Connect the lead wire, and then surround the electrode with an insulating plastic sheet with a thickness of about 2mm to form a length of about 2.5cm and a width of about 0.6mm, with an effective area of 1.5cm 2 slurry room.

[0048] (2) Preparation of tungsten oxide raw material. Weigh 2 grams of 99.9% metal tungsten powder through 300 mesh, spread it in a magnetic evaporation dish, calcinate at 600°C for 2 hours, cool naturally to obtain tungsten oxide particles, and obtain light yellow tungsten oxide powder by ball milling.

[0049] (3) Fabrication of tungsten ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com