Interconnection structure for improving reliability of soldering spot of soft soldering of CCGA (Ceramic Column Grid Array) device and implementation method

An interconnection structure and reliability technology, which is applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of short service life and low reliability, and achieve improved and reliable resistance to mechanical external loads. The effect of improving the performance and reducing the degree of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

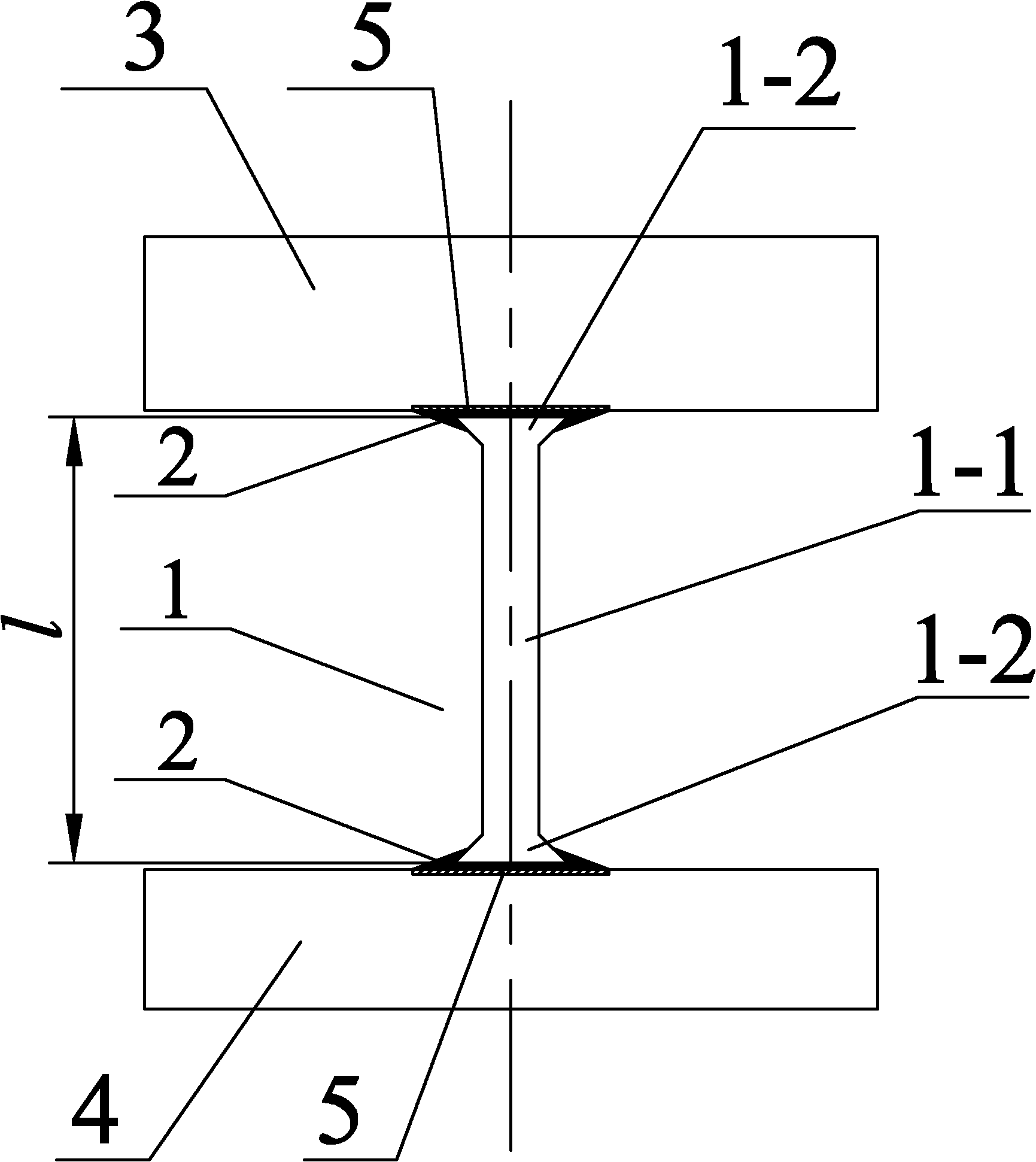

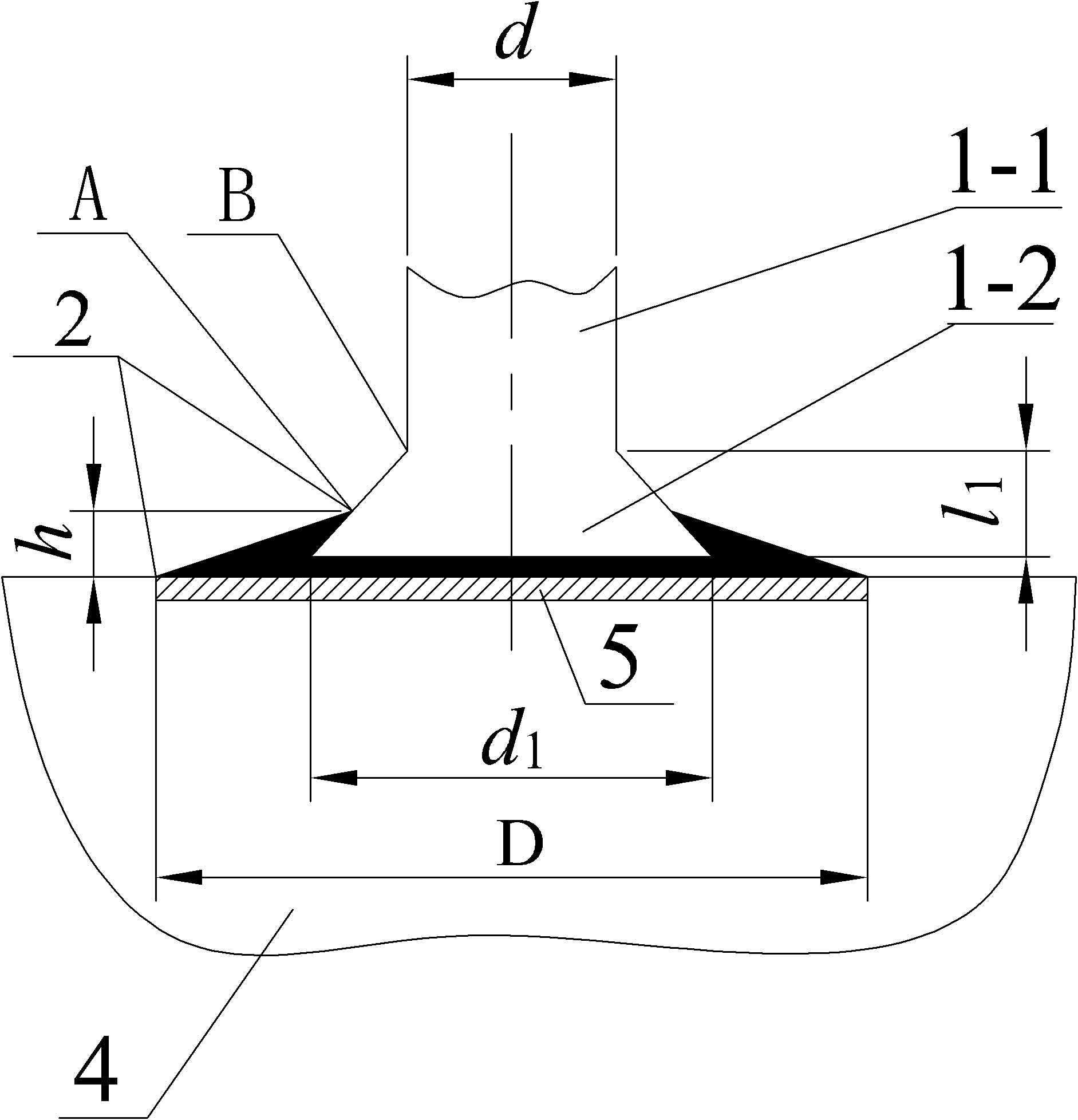

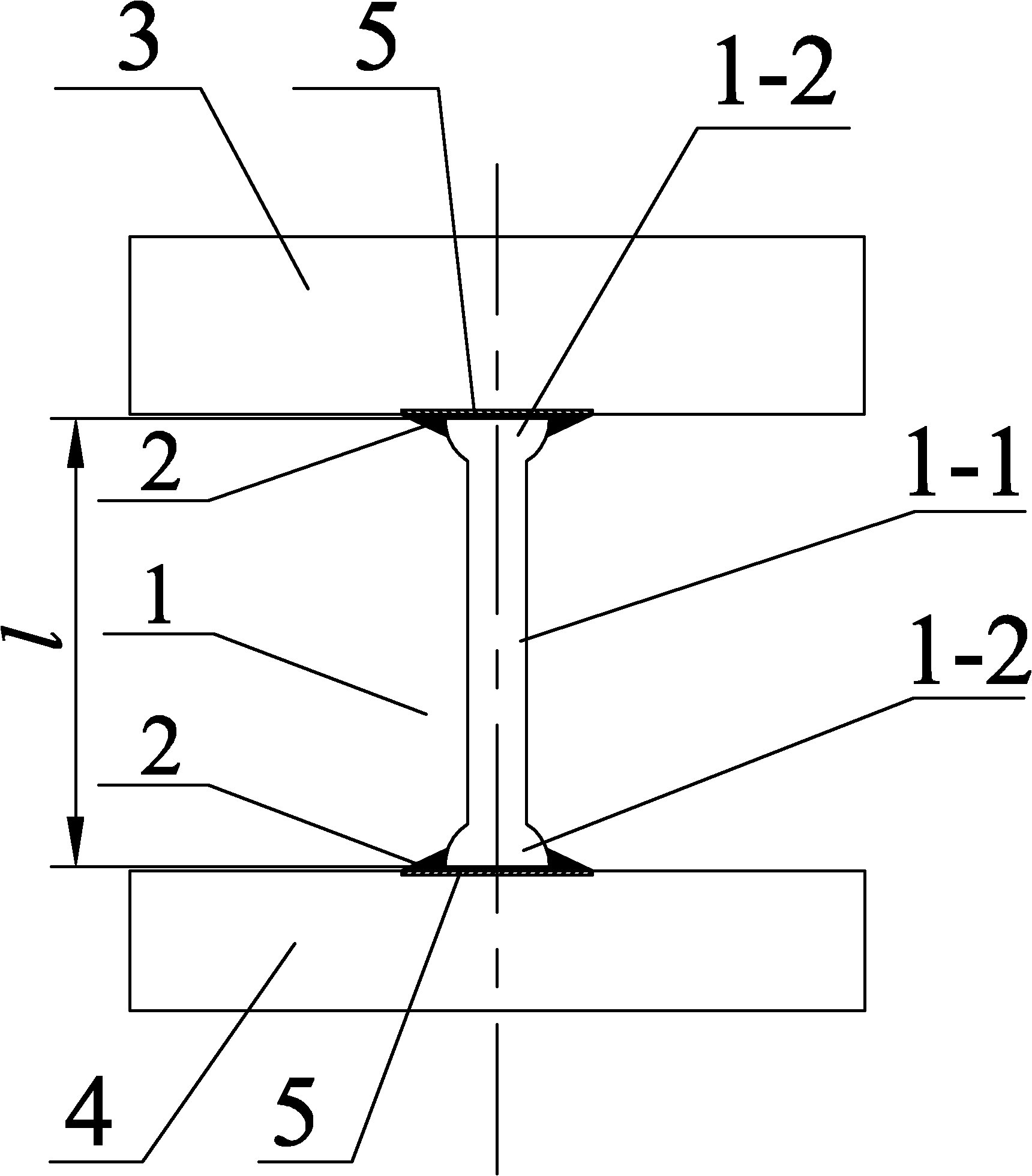

[0034] Specific implementation mode one: as Figure 1a , Figure 1b , Figure 2a , Figure 2b , Figure 3a and Figure 3b As shown, the interconnection structure for improving the reliability of soldering joints of CCGA devices described in this embodiment includes Cu pillars 1 and soldering fillets 2 located at both ends of Cu pillars 1, and the interconnection structure is used to realize chips or The mechanical and electrical connection between the metal film pads 5 on the chip carrier substrate 3 and the metal film pads 5 on the printed circuit board 4, the Cu column 1 is made of a cylinder 1-1 made in one piece and two ends The head 1-2 is formed, and each end 1-2 is in the shape of a rotary body with a straight line or an arc line as a generatrix. Coaxial, smooth transition between the cylinder 1-1 and the end 1-2; the height h of the brazing fillet 2 is less than the height l of the end 1-2 1 .

specific Embodiment approach 2

[0035] Specific implementation mode two: as Figure 1a and Figure 1b As shown, the shape of each end 1-2 in this embodiment is a truncated cone; the two ends of the cylinder 1-1 are respectively integrated with the upper bottom surface (small end face) of one end 1-2. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0036] Specific implementation mode three: as Figure 2a and Figure 2b As shown, the shape of each end 1-2 in the present embodiment is a ball table shape whose lower bottom surface radius is a ball radius (the ball table shape refers to the part where the sphere is cut by two parallel planes and clamped in the middle of the two planes); The two ends of the body 1-1 are made integral with the upper bottom surface (small end surface) of one end 1-2 respectively. Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com