Particulate matter for thermal barrier coating and preparation method thereof, thermal barrier coating and engine

A thermal barrier coating and particle technology, applied in the coating, metal material coating process, application and other directions, can solve the problem of few reports on the structure design of high temperature resistant thermal insulation layer, avoid high temperature sintering closing phenomenon, delay crack Growth, the effect of preventing direct diffusion and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The application provides a method for preparing the particulate matter for thermal barrier coatings, comprising:

[0062] The granules for thermal barrier coating are obtained by agglomerating and granulating the raw materials and inducing plasma spheroidization.

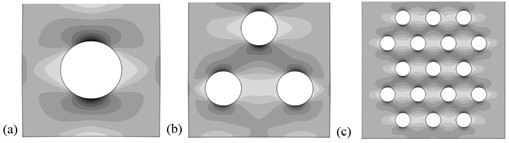

[0063] After agglomeration granulation and induction plasma spheroidization, particles with a loose inner shell and a dense core-shell structure are obtained, in which the internal pores are randomly distributed and have no specific orientation, which ensures that the pore structure in the subsequently prepared coating is also randomly distributed and free. The characteristics of specific orientation make the coating structure isotropic, the properties are more uniform, and the coating cracking caused by stress concentration is reduced.

[0064] In an optional embodiment, the agglomeration and granulation includes:

[0065] Mixing the powder of the raw material on a submicron scale with an organic glue to ob...

Embodiment 1

[0091] This embodiment provides a particle for thermal barrier coating, and its specific preparation method is as follows:

[0092] Using gadolinium zirconate as a raw material, the above particles are prepared through two steps of agglomeration granulation and induction plasma spheroidization.

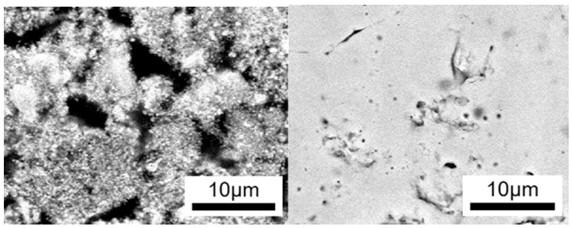

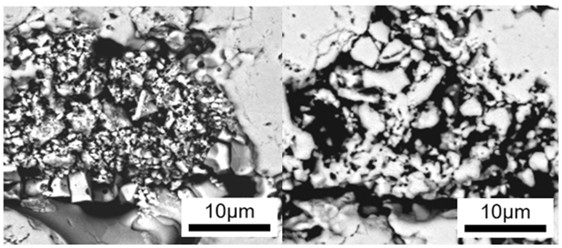

[0093] Among them, agglomeration granulation is to mix submicron-scale fine powder with organic glue (PVA, the mass is 10% of the powder mass) to obtain agglomerated powder by spray drying. The agglomerated powder has a loose and porous internal structure. The average size of microparticles in the agglomerated powder is 0.1 μm, the average size of micropores is 5 μm, and the powder particle size ranges from 10 to 100 μm. Induction plasma spheroidization is to send the agglomerated powder into the high-enthalpy induction plasma formed by radio frequency induction. After the agglomerated powder is heated by the high-temperature plasma, the surface is melted and then cooled to form a den...

Embodiment 2

[0099] This embodiment provides a particle for thermal barrier coating, and its specific preparation method is as follows:

[0100] Using yttria-stabilized zirconia as a raw material, the above particles are prepared through two steps of agglomeration granulation and induction plasma spheroidization.

[0101] Among them, agglomeration granulation is to mix submicron-scale fine powder with organic glue to obtain agglomerated powder by spray drying. The agglomerated powder has a loose and porous internal structure. The average size of microparticles in the agglomerated powder is 1 μm, the average size of micropores is 3 μm, and the powder particle size ranges from 10 to 100 μm. Induction plasma spheroidization is to send the agglomerated powder into the high-enthalpy induction plasma formed by radio frequency induction. After the agglomerated powder is heated by the high-temperature plasma, the surface is melted and then cooled to form a dense shell; the induction plasma process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com