A kind of thermal barrier coating with anti-particle scour surface layer and preparation method thereof

A technology of thermal barrier coating and surface layer, applied in coating, metal material coating process, melt spraying and other directions, can solve complex multi-process, multi-process preparation problems, affect coating performance and life, separation and peeling, etc. problem, to achieve the effect of improving the anti-particle erosion performance, long time and many production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

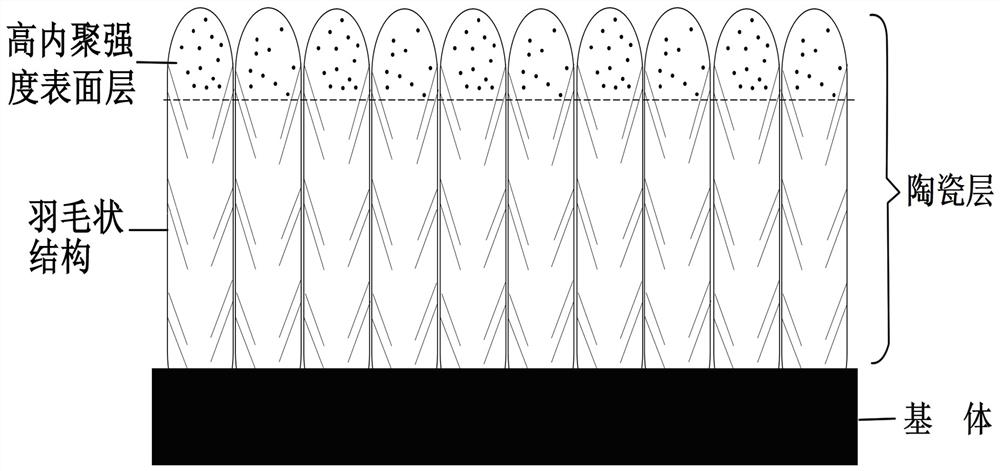

[0024] In this embodiment, superalloy K417G is selected as the base material, and the total coating thickness is designed to be 300 μm, among which the high cohesive strength surface layer is designed to be 50 μm. The thermal barrier coating ceramic layer is made of yttria-stabilized zirconia (YSZ) ceramic powder (agglomerated spherical powder, particle size -30+1 μm, composition as shown in the table below).

[0025] Element ZrO2 Y2O3 HfO2 binder Impurities weight percentage margin 7.5 <2.5

1 <0.1

[0026] Concrete preparation process is as follows:

[0027] In the first step, the surface of the substrate is ground and polished, and the alcohol is ultrasonically cleaned to keep the surface clean;

[0028] The second step is to prepare a ceramic layer on the substrate, the specific steps are as follows:

[0029] (1) Fix the substrate on the workpiece moving table in the vacuum chamber;

[0030] (2) Close the vacuum chamber, evacuate, k...

Embodiment 2

[0039] In this embodiment, the directionally solidified superalloy DZ40M is selected as the substrate, the total coating thickness is designed to be 350 μm, and the anti-particle erosion surface layer is designed to be 70 μm. The material of the thermal barrier coating ceramic layer is yttria stabilized zirconia YSZ.

[0040] Concrete preparation process is as follows:

[0041] In the first step, the surface of the substrate is ground and polished, and the alcohol is ultrasonically cleaned to keep the surface clean;

[0042] The second step is to prepare a ceramic layer on the substrate, the specific steps are as follows:

[0043] (1) Fix the substrate on the workpiece moving table in the vacuum chamber;

[0044] (2) Close the vacuum chamber, evacuate, keep the dynamic pressure of the vacuum chamber equal to 150Pa, and ventilate the vacuum chamber at 1.5L / min;

[0045] (3) Feed in the ceramic layer powder, and the plasma flame flow containing the ceramic layer material swee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com