Method for preparing Schottky contact ZnO nano array ultraviolet detection device

A Schottky contact and nano-array technology, which is applied in the manufacture of semiconductor devices, electrical components, and final products, to achieve the effects of improved absorption, stable performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

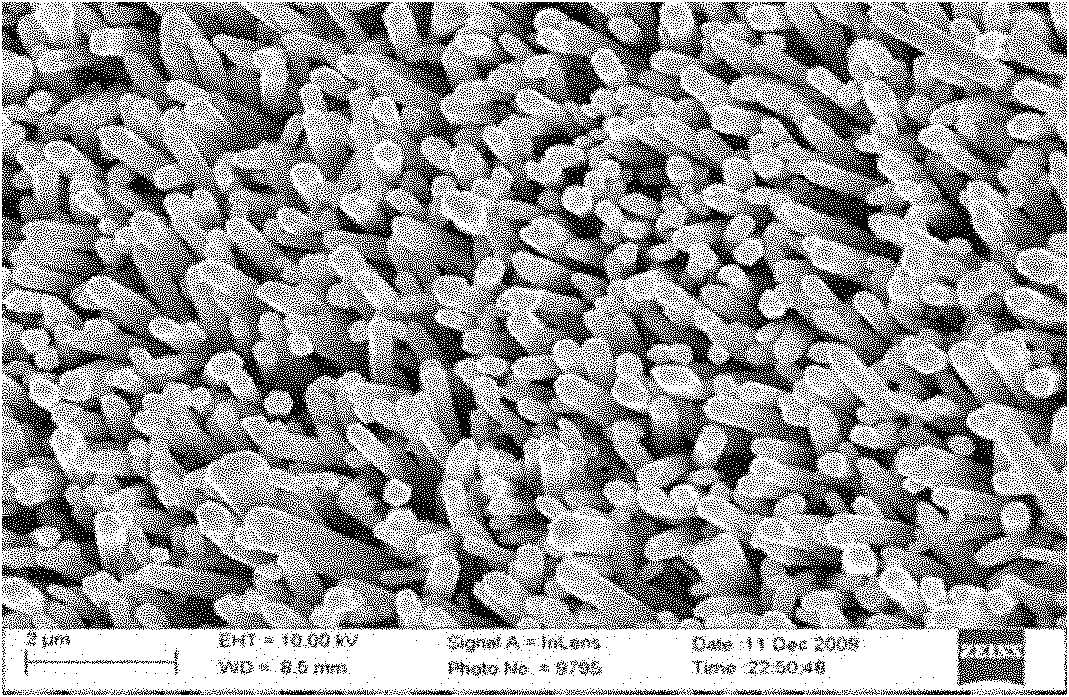

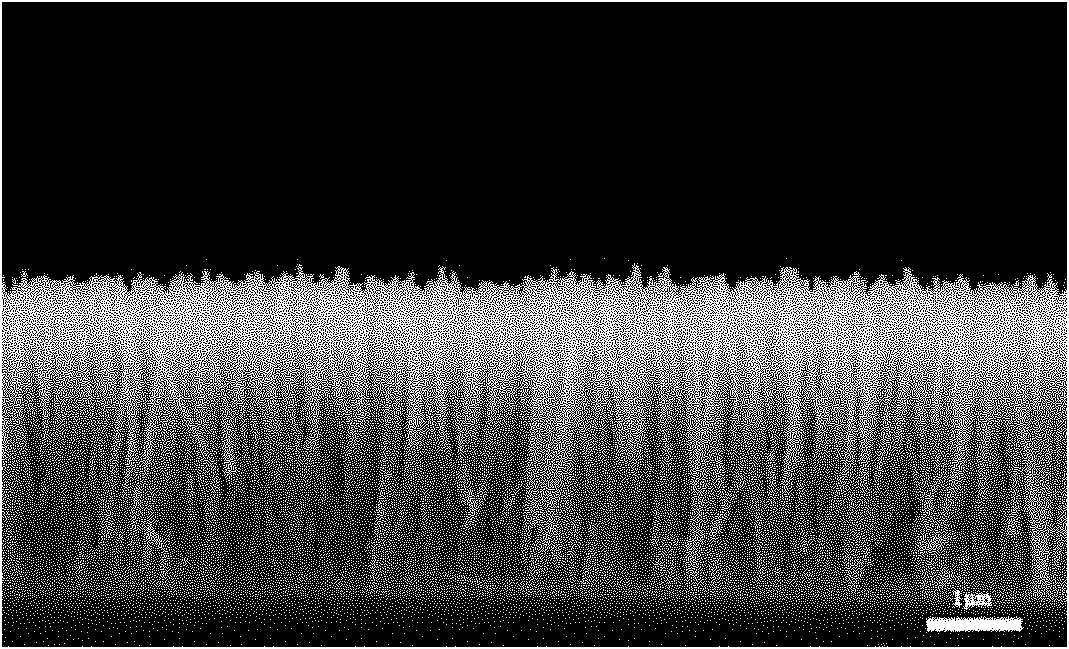

[0024] 1. When growing one-dimensional ZnO nanoarrays by hydrothermal method, first spin-coat a seed solution with a concentration of 0.25 M on the cleaned FTO conductive glass (a mixed solution of zinc acetate, ethylene glycol methyl ether and ethanolamine according to a certain ratio), spin The coating rate was 3000 rpm, the time was 20 s, spin coating 3 times; the crystalline seed layer was fired at 350°C for 30 minutes; proportion of the mixed solution) in a reactor at 95°C for 24 hours. After the reaction, ZnO nano-arrays with a length of 2-3 um and neatly arranged can be obtained.

[0025] 2. When building the device, the dispensed dose of spin-coated PMMA photoresist on the ZnO nanoarrays was 5 ml / 1 × 2 cm 2 , the rotating speed is 2500 rpm, the time is 40 s, spin coating 3 times, so that the PMMA glue is evenly filled between the ZnO nano-arrays, and the thickness of the glue layer is 500 nm; Very good adhesion; when etching by oxygen plasma, set the parameters as ...

Embodiment 2

[0027] 1. When growing one-dimensional ZnO nanoarrays by hydrothermal method, the concentration of seed liquid (zinc acetate, ethylene glycol methyl ether and ethanolamine) was spin-coated on FTO at a concentration of 0.5 M, the spin-coating rate was 3500 rpm, and the time was 20s. times; sinter the crystalline seed layer at 400 °C for 30 minutes in an electric furnace; grow at 95 °C for 24 hours in 0.05 M growth solution (deionized water, zinc nitrate, and hexamethylenetetramine). Compared with Example 1, the ZnO nano-arrays obtained by the reaction are arranged more closely.

[0028] 2. When constructing the device, the dispensed dose is 8ml / 1×2 cm when spin-coating PMMA photoresist on the ZnO nanoarray 2, let stand for 10 s before spin-coating, then set the rotation speed to 3500 rpm, spin-coat for 50 s, spin-coat three times, the thickness of the adhesive layer is 750nm; bake at 175 °C for 2 hours; during oxygen plasma etching, set Air pressure is 10 Pa, power: 100 W, O...

Embodiment 3

[0030] 1. When growing one-dimensional ZnO nanoarrays by hydrothermal method, the concentration of the seed solution (a mixed solution of zinc acetate, ethylene glycol methyl ether and ethanolamine) was spin-coated on FTO at a concentration of 0.5 M, the spin-coating rate was 3500 rpm, and the time was 20s. Spin coating 3 times; sinter the crystalline seed layer at 400 °C for 30 minutes in an electric furnace; grow at 95 °C for 24 hours in a growth solution with a concentration of 0.05 M (a mixed solution of deionized water, zinc nitrate and hexamethylenetetramine) , a neat ZnO nanoarray can be obtained.

[0031] 2. When constructing the device, when the PMMA photoresist is spin-coated on the ZnO nanoarray, the dispensed dose is 8ml / 1×2 cm 2 , the first rotation speed is 600 rpm, spin coating 6 s, the second rotation speed is 3500 rpm, spin coating 60 s, such spin coating process is repeated 3 times, the glue layer thickness is 1000nm, and the photoresist layer of spin coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com