Method for changing material surface nano property

A performance, nano-technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of unsatisfactory surface quality, long nano-coating time, etc., to achieve easy automation, accelerated expansion speed, time reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

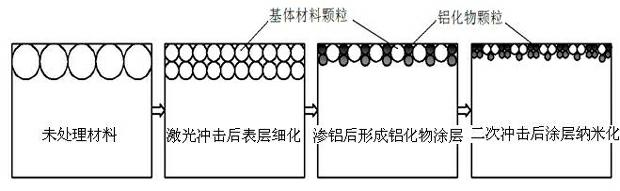

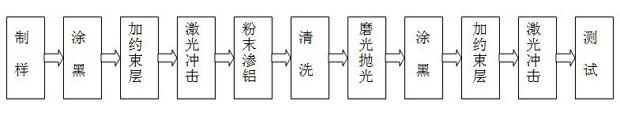

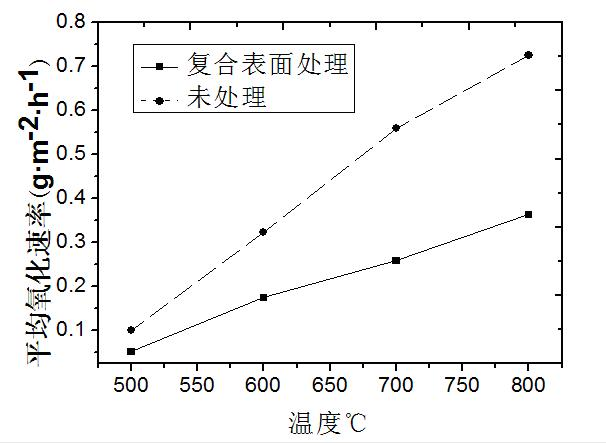

specific Embodiment 1

[0018] Specific embodiment one: taking 00Cr12 alloy heat-resistant steel as an example, carry out the surface treatment method referred to in the present invention, after cleaning and polishing the sample, apply black paint as the energy absorbing layer, and use running water as the constraining layer to carry out laser Impact strengthening, the laser pulse width is 20~30ns, the wavelength is 1.06μm, and the pulse energy is 10~35J. After the impact, micro pits are produced on the surface layer, and the material is refined; then the black paint is cleaned, dried, boxed, and aluminized by heating , The aluminizing process parameters are: 5% to 20% Al-Fe alloy powder for the infiltration agent, 1% to 5% ammonium chloride for the activator, and 60% to 80% alumina powder as the filler. After the aluminized powder is fully mixed, put it into a stainless steel tank, bury the 00Cr12 alloy heat-resistant steel in it, and seal the port with a stainless steel cover plate and refractory so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com