New use and composition of diphenylether pesticide compositions for controlling and killing shoots of citrus crops

A pesticide composition and a technology of diphenyl ethers, which are applied in the field of pesticides, can solve the problems that large-scale planting cannot be removed in time, fruit drop, and labor consumption, etc., and achieve the advantages of increasing fruit yield, reducing production cost, and controlling economic killing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

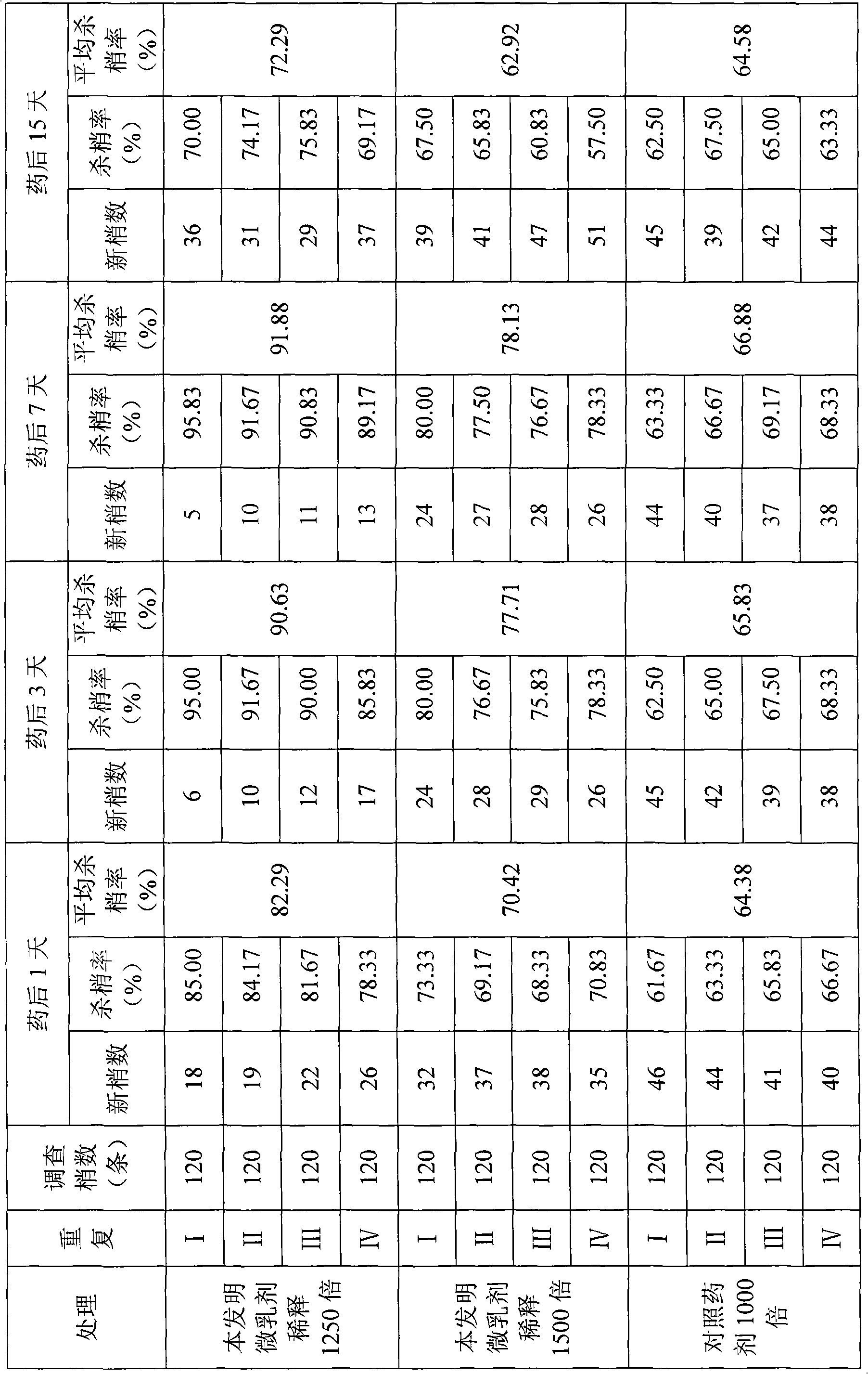

Examples

Embodiment 1

[0043] Weigh the raw material (kg) according to the following mass:

[0044] Oxyfluorfen 8, Azone 2, Methanol 20, Phenylphenol Polyoxyethylene Ether Formaldehyde Condensate 14, Calcium Dodecyl Benzene Sulfonate 15, Water 41.

[0045] Preparation:

[0046] Mix 8 kg of oxyfluorfen, 2 kg of azone, 20 kg of methanol, 14 kg of phenethylphenol polyoxyethylene ether formaldehyde condensate and 15 kg of calcium dodecylbenzenesulfonate, stir well, and finally add 41 kg of water high shear, made of microemulsion.

[0047] The first active ingredient 5-10%, azone 1-3%, methanol 18-22%, phenethylphenol polyoxyethylene ether formaldehyde condensate 12-16%, calcium dodecylbenzenesulfonate 10-20% , the rest is water;

[0048] It is also possible to replace the microemulsion with new dosage forms such as water emulsion, aqueous suspension, wettable powder, and soluble powder.

Embodiment 2

[0050] Weigh the raw material (kg) according to the following mass:

[0051] Ethoxyfluorfen 5, Fomesafen 2.5, Azone 3, Methanol 18, Phenylphenol Polyoxyethylene Ether Formaldehyde Condensate 16, Calcium Dodecyl Benzene Sulfonate 10, Water 45.5.

[0052] The preparation method is as in Example 1.

Embodiment 3

[0054] Weigh the raw material (kg) according to the following mass:

[0055] 15 kg of fenben, 1 kg of fomesafen, 2 kg of azone, 5 kg of sodium naphthalenesulfonic acid formaldehyde condensate, 2 kg of phenylethylphenol polyoxyethylene ether formaldehyde condensate, 3 kg of sodium lignosulfonate, 4 kg of ethylene glycol, 0.1 kg of sodium benzoate, 0.2 kg of silicone defoamer, and 67.7 kg of water.

[0056] Preparation:

[0057] 15 kg of fenben, 1 kg of fomesafen, 2 kg of azone, 5 kg of naphthalenesulfonate formaldehyde condensate sodium salt, 2 kg of phenethylphenol polyoxyethylene ether formaldehyde condensate, 3 kg of sodium lignosulfonate , 4 kilograms of ethylene glycol, 0.1 kilogram of sodium benzoate, 0.2 kilogram of organosilicon defoamer, 67.7 kilograms of water mix uniformly, and through colloid mill, sand mill, make aqueous suspension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com