All-natural feed additive for crustacean and preparation method thereof

A feed additive and crustacean technology, which is applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve the problems of crustacean and human negative effects, such as the impact on the intestinal microecology of crustaceans, and improve the utilization of feed. The effect of high efficiency, wide source and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

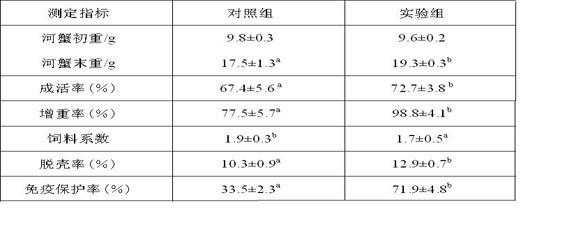

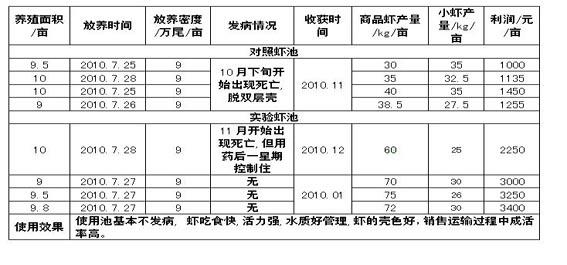

Examples

Embodiment 1

[0034] Embodiment 1: preparation one A pure natural feed additive for crustaceans: in terms of dry matter weight percentage, including 30% of seaweed powder, 15% of egg microcapsule powder, 10% of mugwort leaf powder, 10% of pumpkin powder, and 35% of diluent corn flour. The preparation method of the pure natural feed additive for crustaceans is to use β-cyclodextrin as the wall material to microencapsulate the eggs, the weight of β-cyclodextrin is 15% of the weight of the eggs, spray dry after homogeneous emulsification Obtain egg microcapsule powder, then correctly weigh each of the above-mentioned components, that is, each monomer raw material including diluent, and stir evenly until the coefficient of variation is less than 5% after ultrafine pulverization, so as to obtain a pure natural feed for crustaceans with a particle size of ≤100 mesh additive.

[0035] Among them, the additives prepared in the above steps contain 1.5% of active ingredients calcium, 0.16% of phos...

Embodiment 2

[0036] Embodiment 2: preparation one Pure natural feed additive for crustaceans: in terms of dry matter weight percentage, including seaweed powder 25%, egg microcapsule powder 20%, mugwort leaf powder 10%, pumpkin powder 10%, diluent corn flour 15%, starch 20%. The preparation method is as follows: use β-cyclodextrin as the wall material to microencapsulate eggs, the weight of β-cyclodextrin is 15% of the eggs, homogeneously emulsify, spray dry to obtain egg microcapsule powder, and then weigh it correctly. Measure the above-mentioned components, that is, each monomer raw material including diluent, and after ultrafine grinding, stir until the coefficient of variation is less than 5%, so as to obtain a pure natural feed additive for crustaceans with a particle size of ≤100 mesh.

[0037] Among them, the additives prepared in the above steps contain 1.8% of active ingredients calcium, 0.17% of phosphorus, 0.15% of organic iodine, 5.70% of alginate, 1.4% of mannitol, 0.2% of...

Embodiment 3

[0038] Embodiment 3: preparation one Pure natural feed additives for crustaceans: in terms of dry matter weight percentage, including seaweed powder 30%, egg microcapsule powder 20%, mugwort leaf powder 10%, pumpkin powder 10%, diluent corn flour 15%, starch 15%. The preparation method comprises the following steps: using β-cyclodextrin as wall material to microencapsulate eggs, the weight of β-cyclodextrin being 15% of the eggs, homogeneous emulsification, spray drying to obtain egg microcapsule powder. Then correctly weigh the above-mentioned components, that is, each monomer raw material including the diluent, and stir evenly until the coefficient of variation is less than 5% after superfine pulverization, so as to obtain a pure natural feed additive for crustaceans with a particle size of ≤100 mesh.

[0039] Among them, the additives prepared in the above steps contain 2.5% of active ingredients calcium, 0.18% of phosphorus, 0.4% of organic iodine, 8.0% of alginate, 2.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com