Aluminum-free baking powder

An aluminum-free baking powder, weight percent technology, applied in the field of food additives, to achieve the effects of reducing blood lipids, continuous and uniform bubbles, and good water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

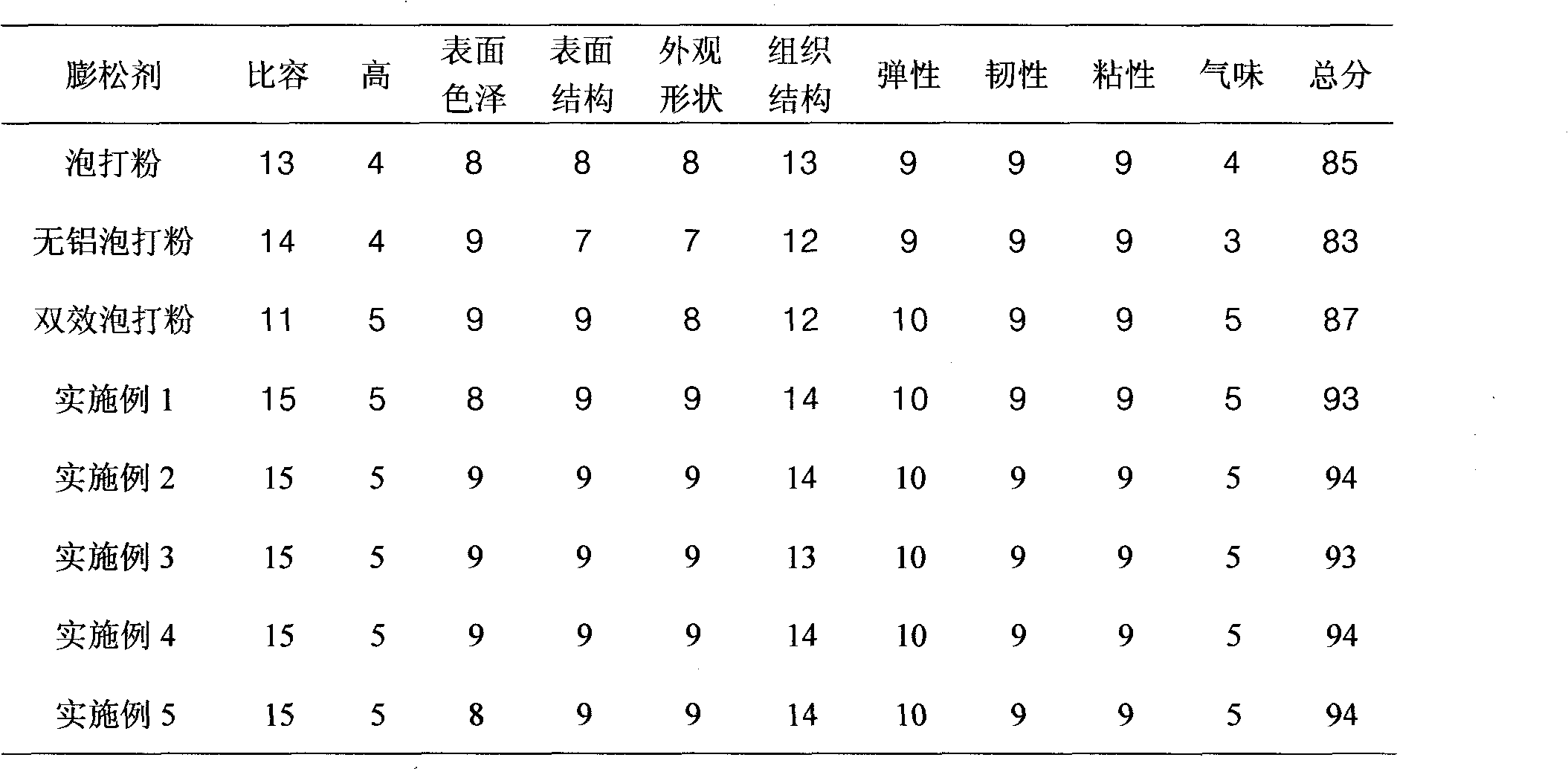

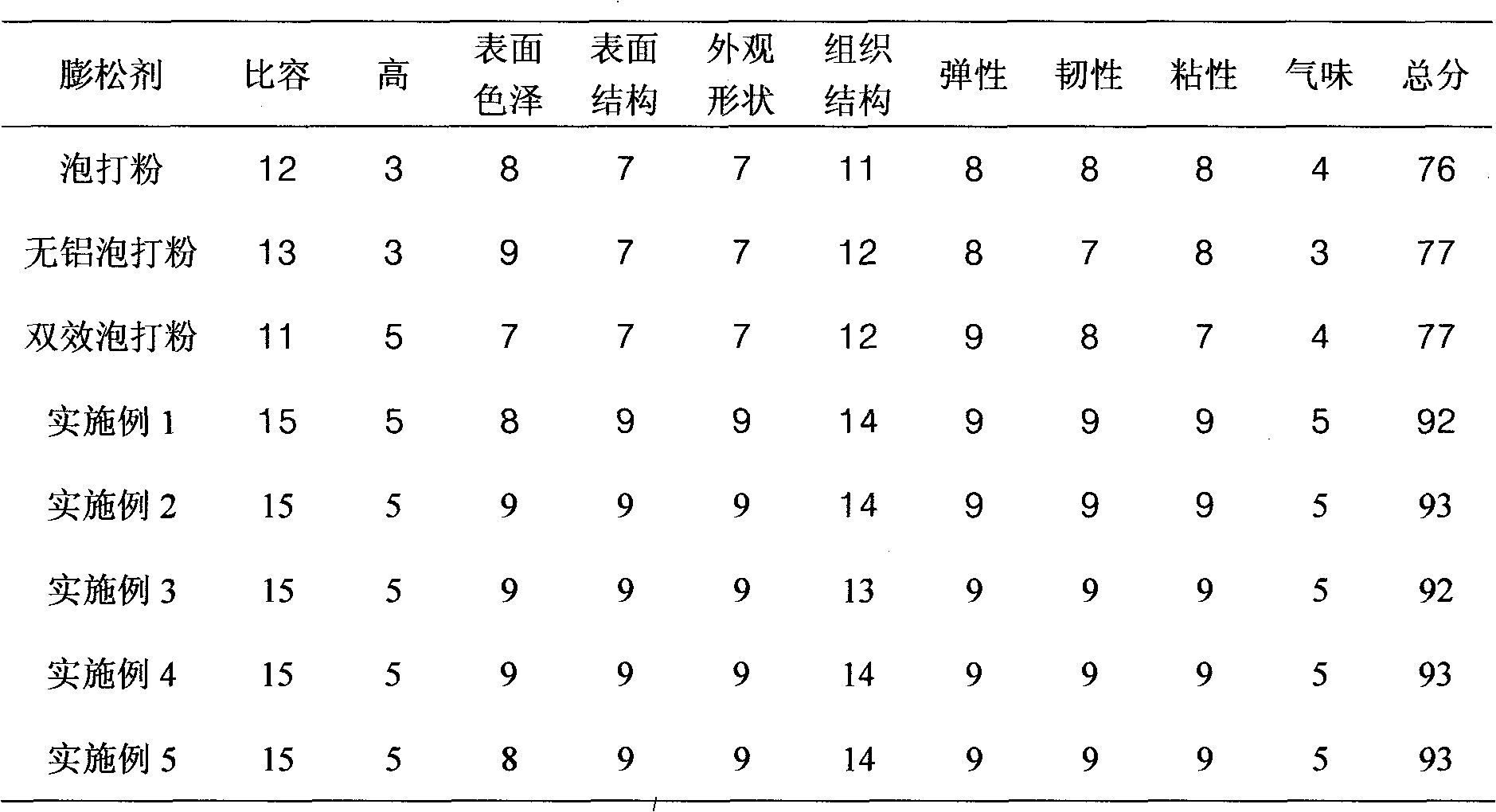

Examples

Embodiment 1

[0026] 40kg sodium bicarbonate, 10kg calcium carbonate, 8kg starch and 6kg glyceryl monostearate and 5kg soybean lecithin were fully dried, pulverized and sieved, premixed in a mixer for 25min, then 23kg glucono-delta-lactone, 4kg Citric acid, 3kg of tartaric acid and 1kg of L-ascorbyl palmitate were put into the mixer and the premixed materials were continuously stirred for 20min to form a uniform mixture.

Embodiment 2

[0028] 38kg sodium bicarbonate, 13kg calcium carbonate, 8kg starch and 7kg glyceryl monostearate and 5kg soybean lecithin are fully dried, pulverized and sieved, premixed in a mixer for 25min, then 21kg glucono-delta-lactone, 3kg Citric acid, 4kg of tartaric acid and 1kg of L-ascorbyl palmitate were put into the mixer and the premixed materials were continuously stirred for 20min to form a uniform mixture.

Embodiment 3

[0030] 37kg sodium bicarbonate, 11kg calcium carbonate, 9kg starch and 4kg glycerol monostearate and 7kg soybean lecithin were fully dried, pulverized and sieved, premixed for 25min in a mixer, then 20kg glucono-delta-lactone, 5kg Citric acid, 5kg of tartaric acid and 2kg of L-ascorbyl palmitate were put into the mixer and the premixed materials were continuously stirred for 20min to form a uniform mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com