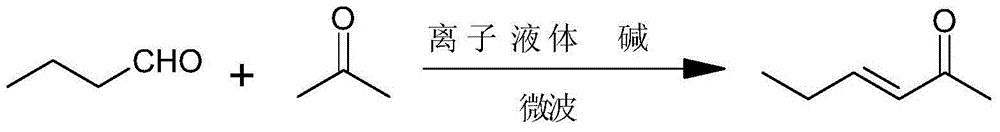

Method for preparing trans3-heptylene-2-ketone

A technology of heptene and acetone, applied in the field of organic compound preparation, can solve the problems of complicated process and high preparation cost, and achieve the effects of stable process, low cost and no industrial wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 7.2g of n-butyraldehyde, 72g of triethylamine sulfate, 7.2g of calcium oxide, and 58g of acetone into the reaction flask, and place it under 200W microwave for TLC tracking until the reaction is complete, which takes about 20 minutes. After the reaction is complete, add 50ml of ethyl acetate, stir and let it stand, divided into upper and lower layers, the upper layer is the ethyl acetate solution of trans-3-hepten-2-one, the lower layer is solid alkali and ionic liquid; the lower layer is acetone Wash, remove acetone, heat the separated solid base and ionic liquid mixture to 60°C, and then dry it under vacuum for 12 hours to obtain the purified solid base and ionic liquid, which can be reused ; The upper liquid was rectified under the conditions of 15mmHg and 65-68°C to obtain 78 grams of trans-3-hepten-2-one, with a yield of 70%.

Embodiment 2

[0025] Add 7.2g of n-butyraldehyde, 72g of diethylamine sulfate, 15g of magnesium oxide, and 108g of acetone into the reaction flask, and place it under 500W microwave for TLC tracking until the reaction is complete, which takes about 10 minutes. After the reaction is complete, add 50ml of ethyl acetate, stir and let it stand, and divide it into upper and lower layers, the upper layer is the ethyl acetate solution of trans-3-hepten-2-one, and the lower layer is solid alkali and ionic liquid;

[0026] The lower layer is washed with acetone to remove acetone, the separated solid base and ionic liquid mixture is heated to 60°C, and then dried under vacuum for 12 hours to obtain the purified solid base and ionic liquid, and the purified solid base and ionic liquid Reusable; the upper liquid is rectified at 15mmHg, 65-68°C,

[0027] 70 g of trans-3-hepten-2-one can be obtained with a yield of 62.5%.

Embodiment 3

[0029] Add 7.2g of n-butyraldehyde, 72g of trimethylamine sulfate, 10g of magnesium oxide, and 108g of acetone into the reaction flask, and place it under 500W microwave for TLC tracking until the reaction is complete, which takes about 15 minutes. After the reaction is complete, add 50ml of ethyl acetate, stir and let it stand, and divide it into upper and lower layers, the upper layer is the ethyl acetate solution of trans-3-hepten-2-one, and the lower layer is solid alkali and ionic liquid;

[0030] The lower layer is washed with acetone to remove acetone, the separated solid base and ionic liquid mixture is heated to 60°C, and then dried under vacuum for 12 hours to obtain the purified solid base and ionic liquid, and the purified solid base and ionic liquid Reusable; the upper liquid is rectified at 15mmHg, 65-68°C,

[0031] 74 g of trans-3-hepten-2-one can be obtained with a yield of 66.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com