Radiation detector

A radiation detector and detector technology, applied in radiation control devices, semiconductor devices, discharge tubes, etc., can solve the problems of increasing material thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

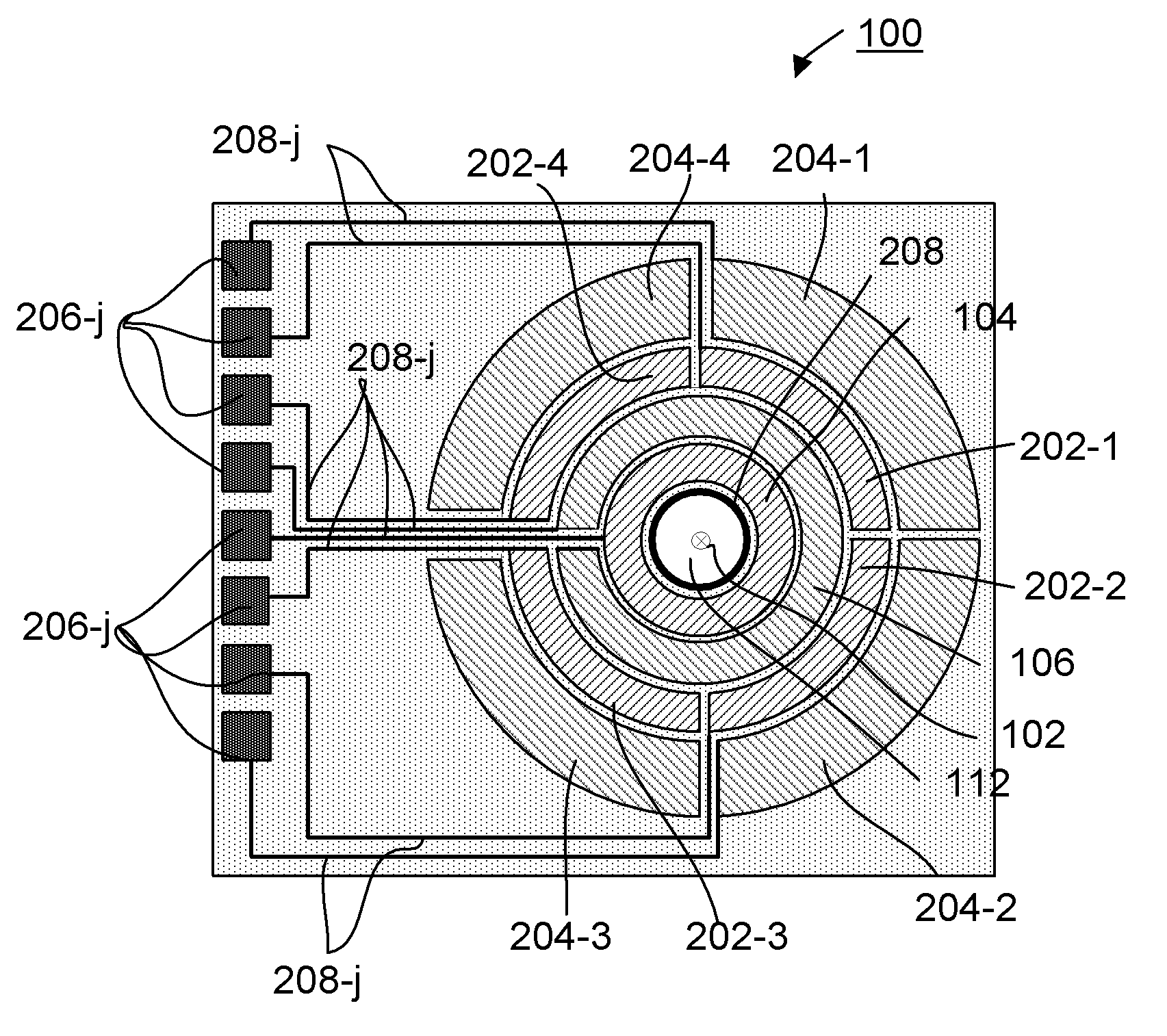

[0078] figure 1 A cross-section of a sensor including a plurality of detectors according to the present invention is schematically shown.

[0079] It shows the sensor 100, which is shown symmetrical about the axis 102. The sensor shows two detectors 104 and 106, each having an area sensitive to radiation. The detector can be a ring detector, but each ring can be further divided into segments, such as three 120° segments, or four 90° segments, each of which forms a separate detector.

[0080] The sensor includes an n-type substrate 108 that is metalized on one side, thereby forming a back electrode 110. On the other side of the substrate, an intrinsic layer in the form of an epitaxial layer 116 is formed to have a thickness of, for example, 40 μm. On top of the epitaxial layer, the boron layer 118 is deposited, thereby forming the p of the silicon boride layer 120 + Type diffusion layer. Around the radiation-sensitive area, a p-doped (boron-doped) boundary 122 is formed. The de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com