Method for preparing dichloro(1,5-cyclooctadiene)platinum(II)

A technology for the preparation of cyclooctadiene, which is applied in the field of preparation of dichloro(1,5-cyclooctadiene) platinum (II), can solve the problems of waste of raw materials, environmental damage, harsh conditions and dangers, and achieve Reduce reaction time, reduce waste of raw materials, and reduce environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

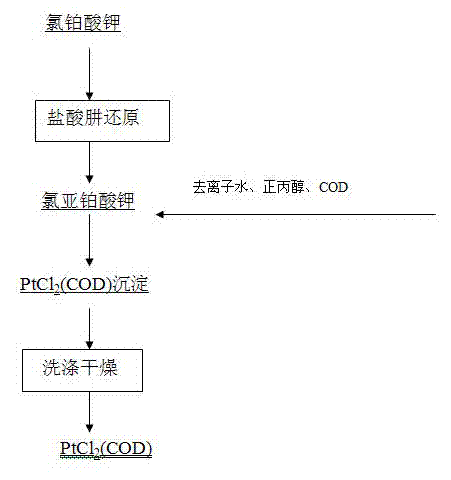

Image

Examples

preparation example Construction

[0011] A kind of preparation method of dichloro (1,5-cyclooctadiene) platinum (II), with potassium chloroplatinite, COD as raw material, with n-propanol as solvent, prepare noble metal catalyst dichloro (1 ,5-cyclooctadiene) a new method for platinum(II). Specific methods include:

[0012] (ⅰ) Put a certain amount of n-propanol and water (volume ratio 1.0 to 3.0:1) in step (ⅰ) in a 50L jacketed glass reactor, the inlet and outlet of the jacket are connected to the circulating oil bath heater, and the reactor The upper end is connected to the condenser tube. Stir evenly, add a certain amount of 1,5-cyclooctadiene (COD), wait for the temperature to rise to 60-90°C, add a certain amount of potassium chloroplatinite, maintain the oil bath temperature at 60-90°C, and react for 3- 4h, milky white precipitate and mother liquor were obtained;

[0013] (ii) Cool the suspension in step (i) to room temperature, vacuum filter, wash with absolute ethanol and deionized water three times ...

Embodiment 1

[0015] Add 200ml of n-propanol and 200ml of deionized water into a 2L three-necked flask, stir well, add 50ml of 1,5-cyclooctadiene (COD), wait until the temperature of the oil bath rises to 85°C, add 50g of potassium chloroplatinite, keep The oil bath temperature was 85°C for 3.5 hours, and a milky white precipitate was precipitated, cooled to room temperature, filtered with suction, washed with absolute ethanol and deionized water three times, dried and weighed. The product yield is 94.0%, and the elemental analysis results are C: 25.82%, H: 3.266%, and Pt: 52.64%.

Embodiment 2

[0017] The specific implementation rules are the same as in Example 1, except that 1L of deionized water, 1L of n-propanol, 250ml of COD, and 250g of potassium chloroplatinite are added to a 5L three-necked flask and reacted in an oil bath at 85°C for 3.5h; The yield was 96.04%; the elemental analysis results were C: 25.15%, H: 3.123%, and Pt: 52.13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com