Radiation-resistant high-performance silica fiber and preparation method thereof

A technology of quartz optical fiber and manufacturing method, which is applied in the direction of manufacturing tools, glass molding, glass manufacturing equipment, etc., can solve the problems affecting long-distance communication, large transmission attenuation of near-infrared communication window, etc., so as to improve production efficiency and radiation resistance capacity and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

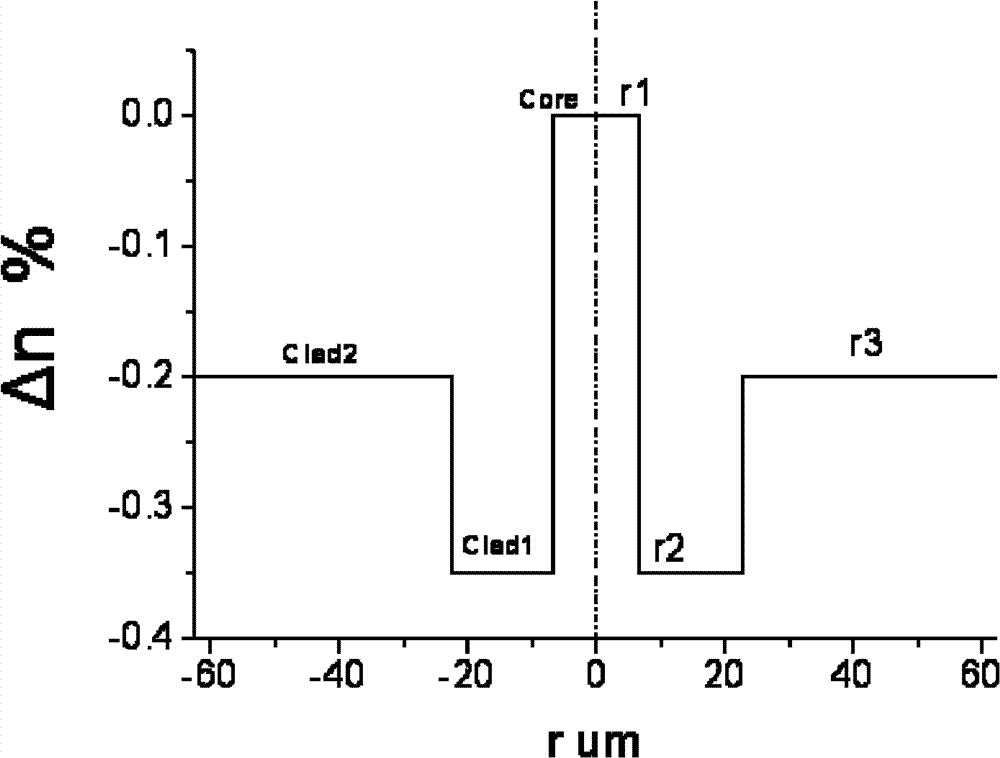

[0035] Such as Figure 1A Shown is the optical fiber waveguide refractive index profile of this embodiment, and the following are optical fiber structural parameters:

[0036] The core (also called the core layer) Core is pure silica glass, and the relative refractive index difference Δn of the core relative to pure silica glass 1 About 0, the core radius r1 is about 6.6um;

[0037] The inner cladding Clad1 is a silica glass layer doped with 10000ppm fluorine, and the relative refractive index difference Δn of the inner cladding relative to pure silica glass 2 About -0.35%, inner cladding radius r2 is about 16um;

[0038] The outer cladding layer Clad2 is a silica glass layer doped with 5000ppm fluorine, and the relative refractive index difference Δn of the outer cladding layer relative to pure silica glass 3 About -0.2%, the outer cladding radius r3 is 39.9um;

[0039] The dispersion curve of the obtained optical fiber versus wavelength is as follows Figure 4A In the cu...

Embodiment B

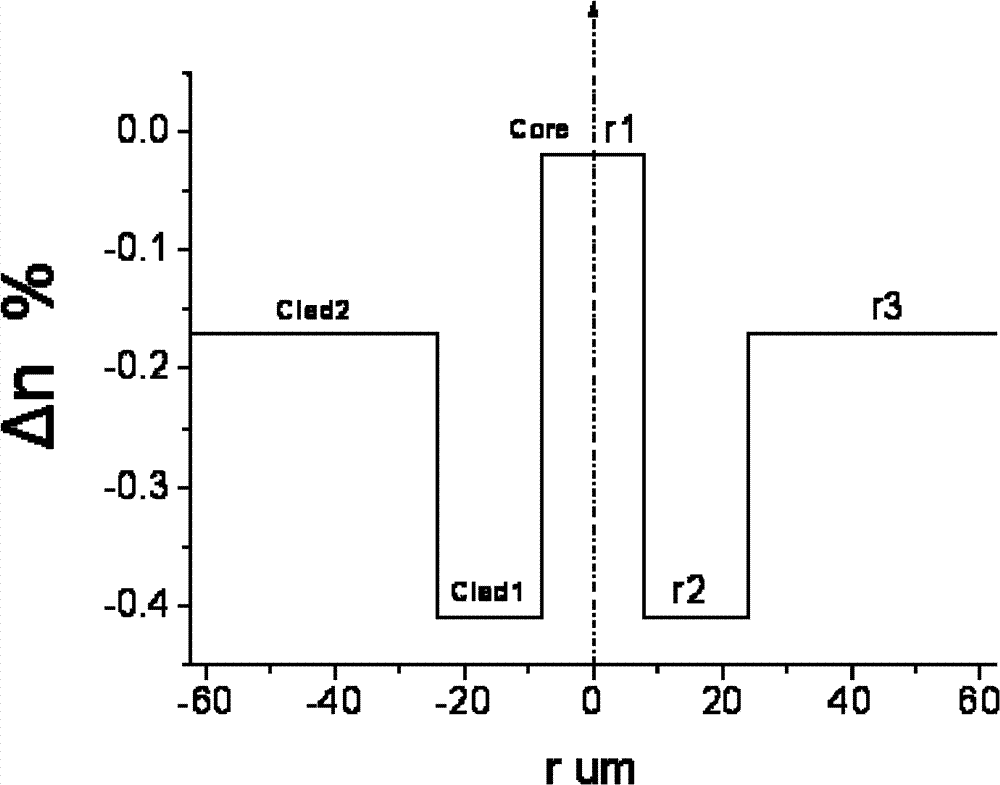

[0046] Such as Figure 1B Shown is the optical fiber waveguide refractive index profile of this embodiment, and the following are optical fiber structural parameters:

[0047] The core layer Core is 500ppm fluorine-doped silica glass, the relative refractive index difference Δn1 of the core relative to pure silica glass is about -0.02%, and the core radius r1 is about 8um;

[0048] The inner cladding Clad1 is 10800ppm fluorine-doped silica glass, the relative refractive index difference Δn2 of the inner cladding relative to the pure silica glass is about -0.38%, and the radius r2 of the inner cladding is about 16um;

[0049] The outer cladding Clad2 is 4300ppm fluorine-doped silica glass layer, the relative refractive index difference Δn3 of the outer cladding relative to the pure silica glass is about -0.15%, and the outer cladding radius r3 is 38.5um.

[0050] The dispersion curve of the obtained optical fiber versus wavelength is as follows Figure 4A In the curve B, the ...

Embodiment C

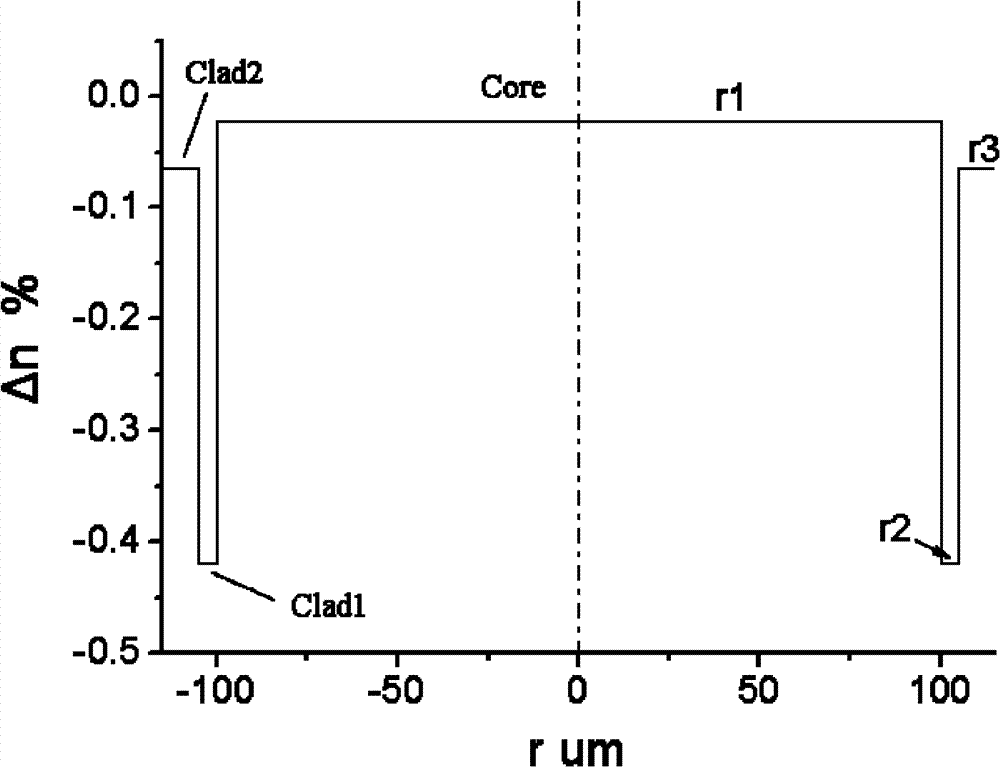

[0057] Such as Figure 1C Shown is the optical fiber waveguide refractive index profile of this embodiment, and the following are optical fiber structural parameters:

[0058] The core layer Core is silica glass doped with 200ppm hydroxyl and 500ppm fluorine, the relative refractive index difference Δn1 of the core relative to pure silica glass is about -0.02%, and the core radius r1 is about 100um;

[0059] The inner cladding Clad1 is 12000ppm fluorine-doped silica glass, the relative refractive index difference Δn2 of the inner cladding relative to the pure silica glass is about -0.42%, and the radius r2 of the inner cladding is about 5um;

[0060] The outer cladding Clad2 is a 1700ppm fluorine-doped silica glass layer, the relative refractive index difference Δn3 of the outer cladding relative to the pure silica glass is about -0.06%, and the outer cladding radius r3 is about 10um.

[0061] The above-mentioned radiation-resistant high-performance silica fiber adopts a mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com