Method for reclaiming fluorine-containing and ammonia nitrogen-containing waste water in electronic industry

A technology for electronics industry, ammonia nitrogen wastewater, applied in chemical instruments and methods, water pollutants, water/sewage multi-stage treatment, etc. and other problems, to achieve stable and good treatment effect, reduce ammonia nitrogen content, and reduce wastewater discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

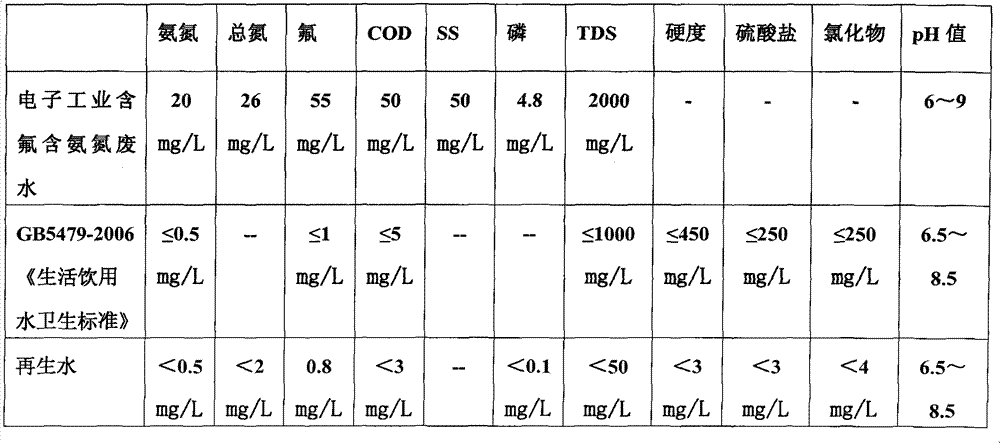

[0032] The wastewater containing fluorine and ammonia nitrogen in an electronics industry contains a large amount of pollutants such as fluorine, ammonia nitrogen, organic nitrogen, phosphorus and suspended solids, and the total dissolved solid salt content in the water is relatively high. See Table 1-1 for the specific content of main pollutants in wastewater.

[0033] Table 1-1 Contents of main pollutants in wastewater containing fluorine and ammonia nitrogen

[0034]

Ammonia nitrogen

Ammonia nitrogen / fluoride ion

COD

SS

TDS

pH value

20mg / L

26mg / L

55mg / L

0.36

50mg / L

50mg / L

4.8mg / L

2000mg / L

6~9

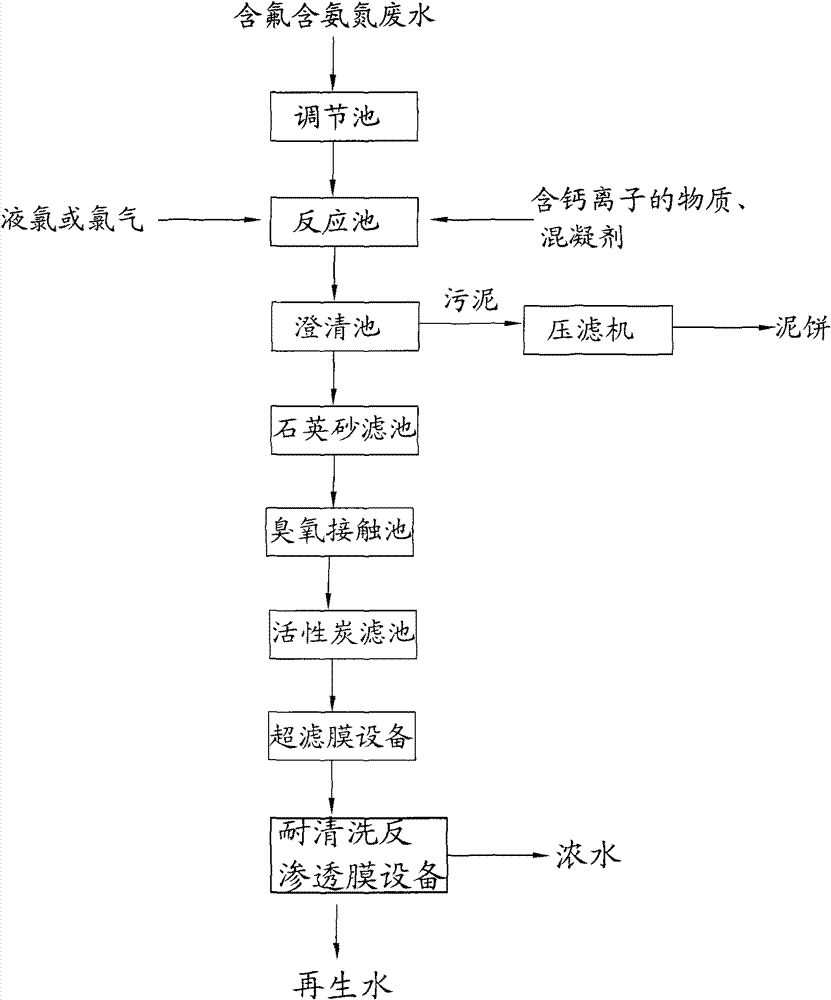

[0035] Such as figure 1 As shown, the waste water passes through the adjustment tank, reaction tank, clarification tank and V-shaped quartz sand filter tank, ozone contact tank, activated carbon filter...

Embodiment 2

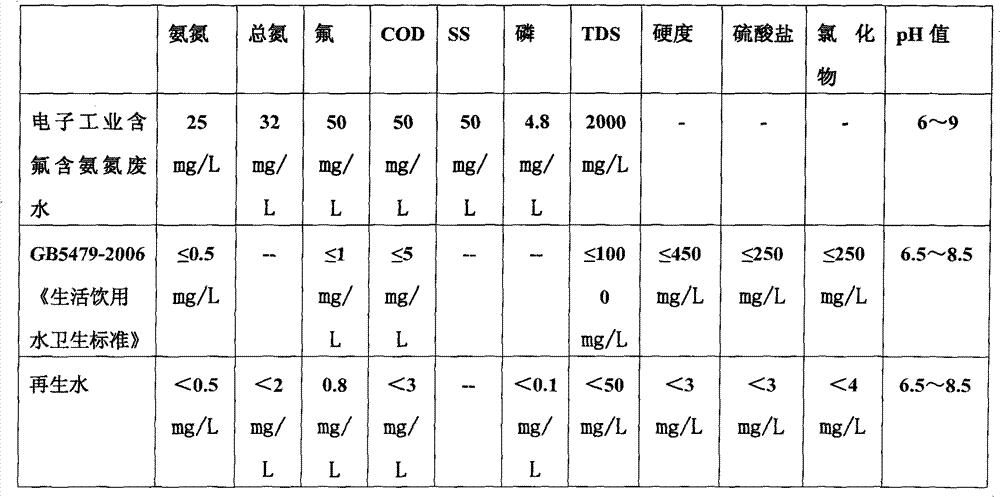

[0057] The wastewater containing fluorine and ammonia nitrogen in an electronics industry contains a large amount of pollutants such as fluorine, ammonia nitrogen, organic nitrogen, phosphorus and suspended solids, and the total dissolved solid salt content in the water is relatively high. See Table 2-1 for the specific content of main pollutants in wastewater.

[0058] Table 2-1 Contents of main pollutants in wastewater containing fluorine and ammonia nitrogen

[0059] Ammonia nitrogen

Ammonia nitrogen / fluoride ion

COD

SS

phosphorus

TDS

pH value

25mg / L

32mg / L

50mg / L

0.50

50mg / L

50mg / L

4.8mg / L

2000mg / L

6~9

[0060] According to the wastewater treatment method of this embodiment, it is basically the same as that of Example 1, except that there are slight changes in the operation of the ammonia nitrogen removal process and the fluorine removal process, as follow...

Embodiment 3

[0065] The wastewater containing fluorine and ammonia nitrogen in an electronics industry contains a large amount of pollutants such as fluorine, ammonia nitrogen, organic nitrogen, phosphorus and suspended solids, and the total dissolved solid salt content in the water is relatively high. See Table 3-1 for the specific content of main pollutants in wastewater.

[0066] Table 3-1 Contents of main pollutants in wastewater containing fluorine and ammonia nitrogen

[0067] Ammonia nitrogen

total nitrogen

Fluoride ion

Ammonia nitrogen / fluoride ion

COD

SS

phosphorus

TDS

pH value

35mg / L

43mg / L

37mg / L

0.95

50mg / L

50mg / L

4.8mg / L

2000mg / L

6~9

[0068] According to the wastewater treatment method of this embodiment, it is basically the same as that of Example 1, except that there are slight changes in the operation of the ammonia nitrogen removal process and the fluorine removal process, as follows:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com