Non-vacuum solar spectrum selective absorption coating and preparation method thereof

A technology of absorbing coating and solar spectrum, applied in the field of solar thermal utilization materials, can solve the problems of intolerant of oxidation and low operating temperature, and achieve the effects of low cost, high resistivity and excellent dielectric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

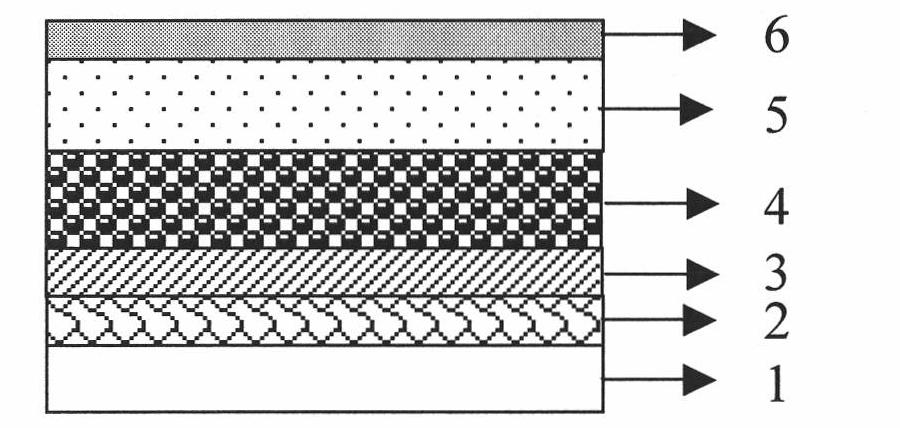

[0047] (1) select stainless steel as the substrate 1;

[0048] (2) Select titanium aluminum as the film layer material (transition layer) 2;

[0049] (3) Titanium nitride is selected as the film material (high infrared reflective layer) 3;

[0050] (4) Select a (titanium nitride-aluminum nitride) film with a high titanium nitride content as the film material (the first absorption layer) 4;

[0051] (5) Select a (titanium nitride-aluminum nitride) thin film with low titanium nitride content as the film material (the second absorption layer) 5;

[0052] (6) Select aluminum nitride as the film material (anti-reflection layer) 6;

[0053] (7) A multi-target composite coating machine is used for coating; in order to improve the bonding force between the film and the substrate, the substrate material is ultrasonicated in sulfuric acid, detergent, deionized water, gasoline, and ethanol for 5 to 30 minutes before being placed in a vacuum chamber. Drying; after placing in a vacuum c...

Embodiment 2

[0064] (1) select stainless steel as the substrate 1;

[0065] (2) Select titanium-aluminum thin film as transition layer 2;

[0066] (3) Select titanium aluminum nitride film as the high infrared reflective layer 3;

[0067] (4) Select a (titanium aluminum nitride-aluminum nitride) thin film with a high content of titanium aluminum nitride as the film material, that is, the first absorption layer 4;

[0068] (5) Select a (titanium aluminum nitride-aluminum nitride) thin film with a low content of titanium aluminum nitride as the film material, that is, the second absorption layer 5;

[0069] (6) An aluminum nitride film is selected as the anti-reflection layer 6 .

[0070] (7) A multi-target composite coating machine is used for coating; in order to improve the bonding force between the film and the substrate, the substrate material is ultrasonicated in sulfuric acid, detergent, deionized water, gasoline, and ethanol for 5 to 30 minutes before being placed in a vacuum chamb...

Embodiment 3

[0074] (1) select stainless steel as the substrate 1;

[0075] (2) Select titanium-aluminum thin film as transition layer 2;

[0076] (3) select titanium nitride film as the high infrared reflective layer 3;

[0077] (4) Select a (titanium nitride-aluminum oxide) thin film with a high titanium nitride content as the film material, that is, the first absorption layer 4;

[0078] (5) Select a (titanium nitride-aluminum oxide) thin film with low titanium nitride content as the film material, that is, the second absorption layer 5;

[0079] (6) An aluminum oxide thin film is selected as the anti-reflection layer 6 .

[0080] (7) A multi-target composite coating machine is used for coating; in order to improve the bonding force between the film and the substrate, the substrate material is ultrasonicated in sulfuric acid, detergent, deionized water, gasoline, and ethanol for 5 to 30 minutes before being placed in a vacuum chamber. Drying; after placing in a vacuum chamber, bake a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com