Porous metal electrode for multistage depressed collector

A technology of porous metal and collector, which is applied to collectors and traveling wave tubes of time-of-flight electron tubes, can solve the problems of multi-stage step-down collectors suppressing secondary electrons, and achieve the effect of improving efficiency and suppressing emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention uses the known electric spark wire cutting method, electric spark corrosion method or ion bombardment method to manufacture the electrode of the multi-stage step-down collector.

[0031] The porous metal material of the present invention can adopt existing porous nickel, porous tungsten and porous molybdenum materials in the domestic and foreign markets; its pore size is not strictly required, and the preferred pore size can be 20% to 40%.

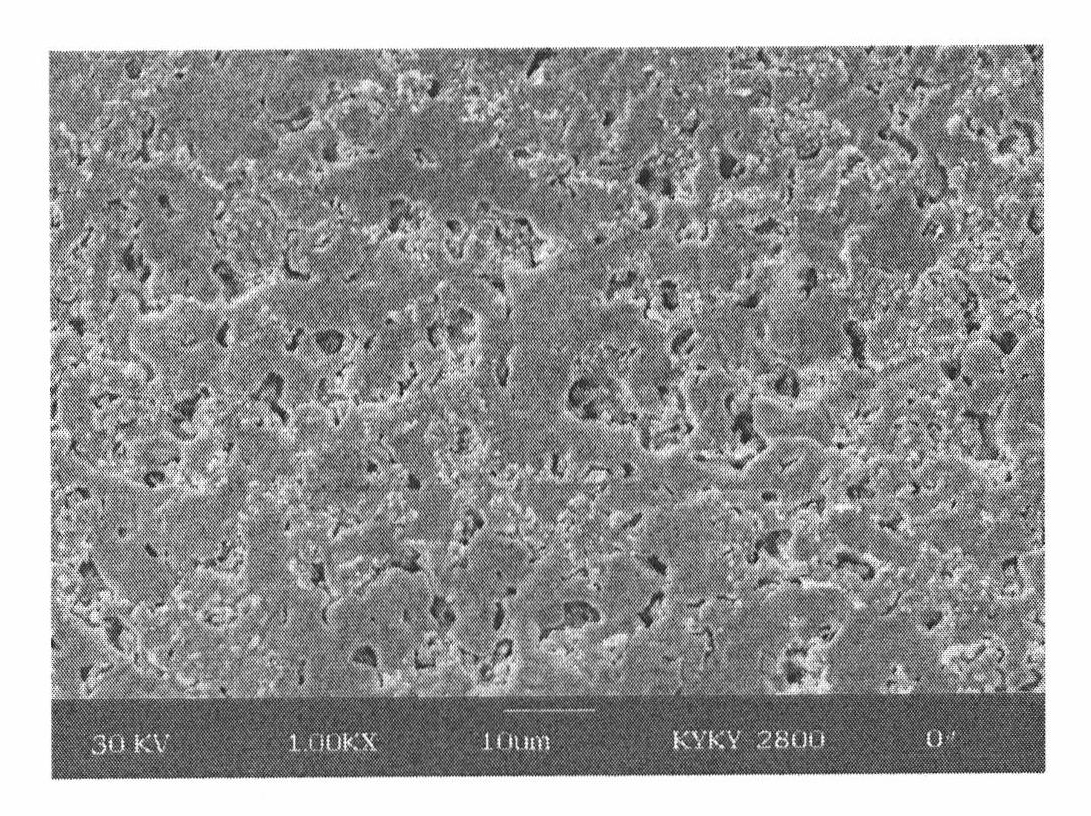

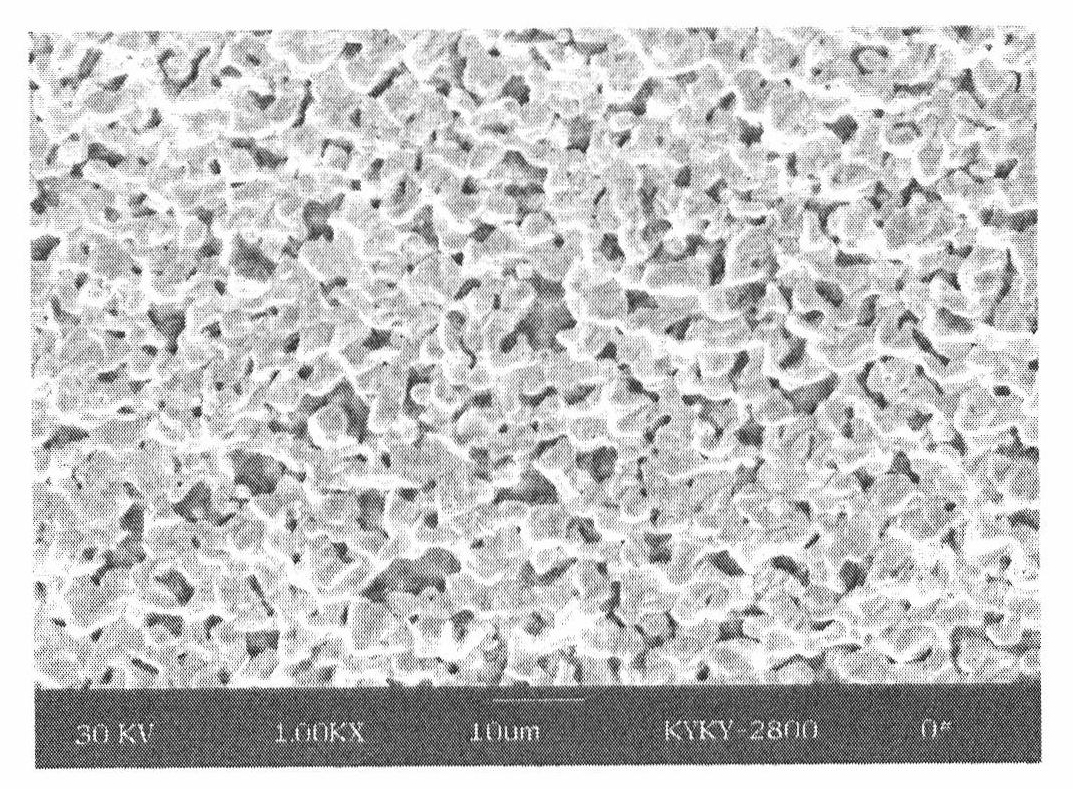

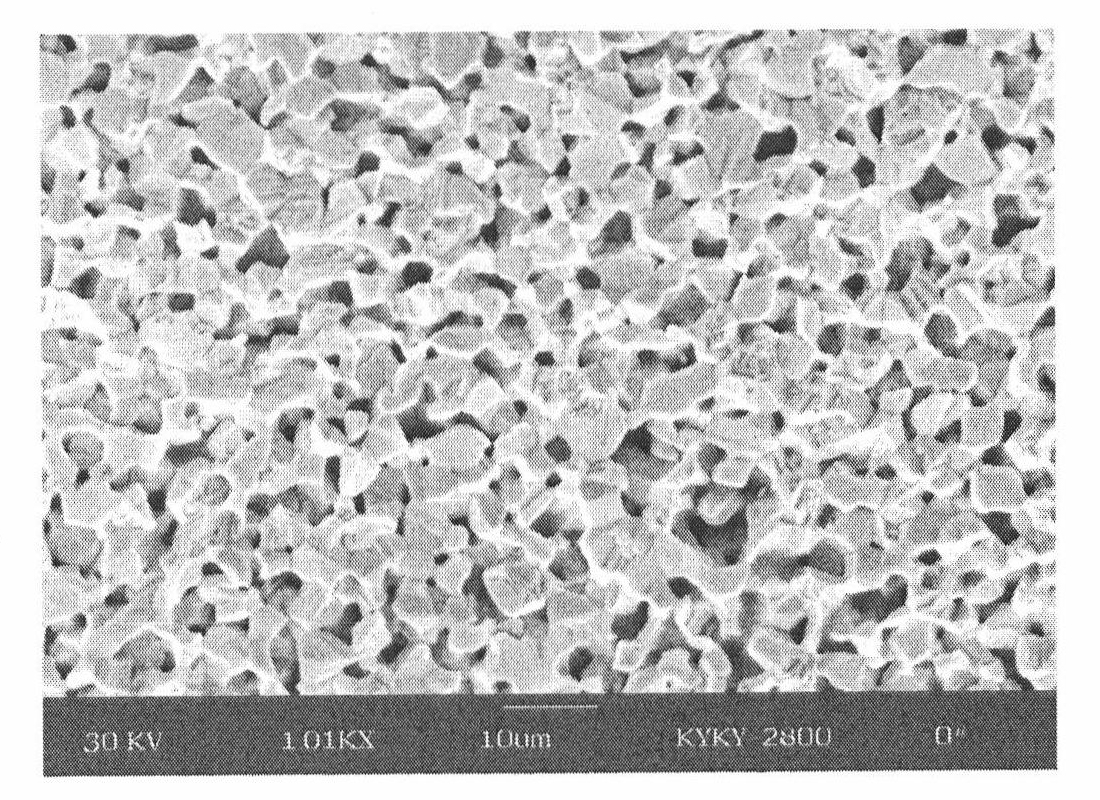

[0032] After the porous material is chemically cleaned, the electrode surface of the multi-stage step-down collector electrode is treated with a wire electric discharge method, an electric spark corrosion method or an ion bombardment method, so that the bombarded surface exposes a surface morphology with many pits.

[0033] The present invention uses the ion bombardment method to bombard the electrode surface, and after observing with an electron microscope, a large number of expected pits (such as figure 2 shown).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com