Preparation method of molybdenum disulfide nano-fibers

A technology of nanofibers and molybdenum disulfide, applied in fiber treatment, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of low aspect ratio of nanomaterials, harsh preparation process conditions, complex devices, etc., and meet the requirements of environmental conditions Low cost, easy access to raw materials, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Polyvinyl alcohol with an average degree of polymerization of 1700 and a degree of alcoholysis of 88% is selected for use.

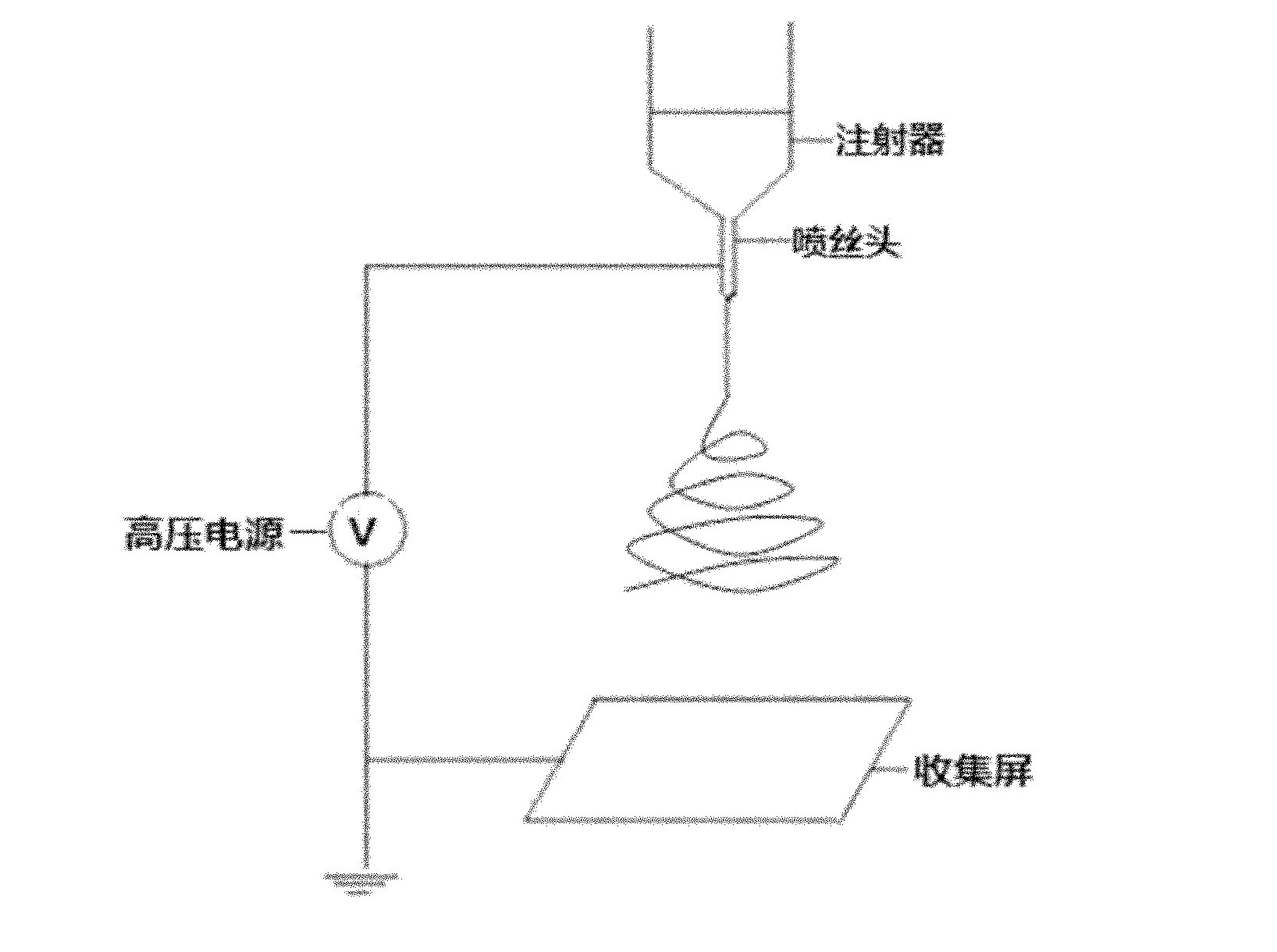

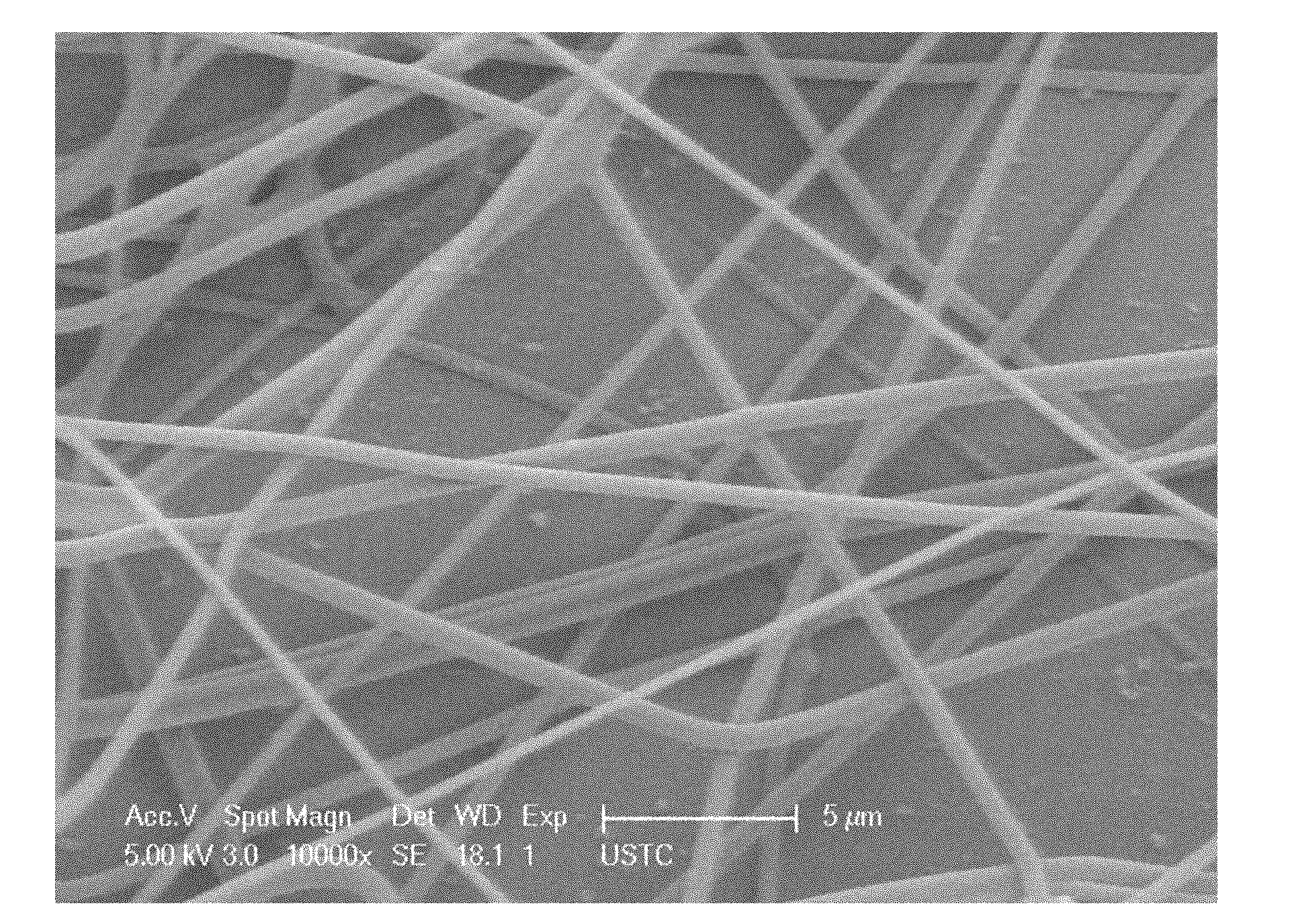

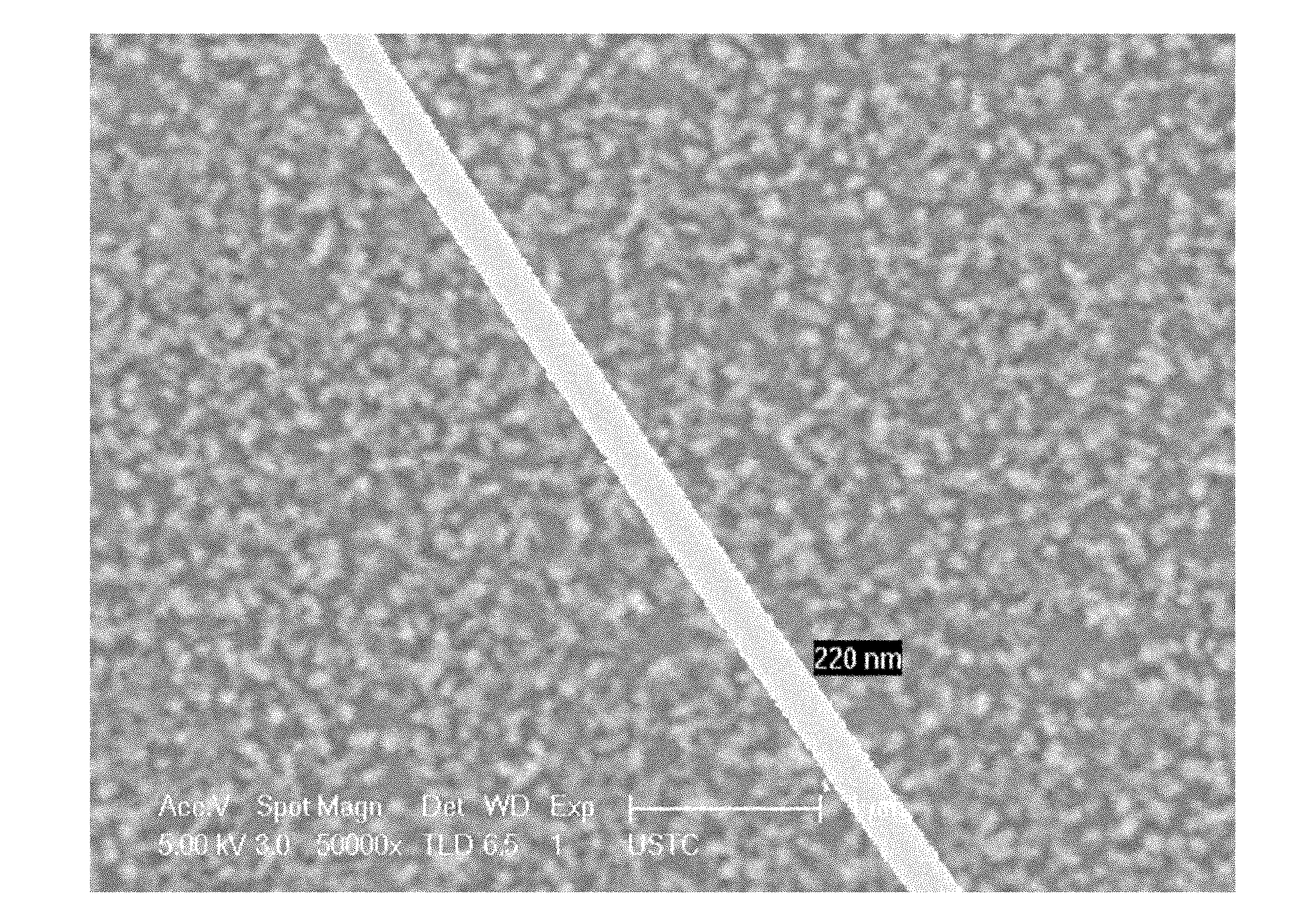

[0014] Weigh 20g of polyvinyl alcohol powder, fully swell in 200ml of deionized water for 2h, then heat in a water bath to 90°C and stir for 6h (covered with plastic wrap to prevent water evaporation), to obtain a viscous PVA solution (concentration 10wt%), measure 20ml to be use. Use a beaker to measure 5ml of dimethyl sulfoxide, weigh 0.6g of ammonium tetrathiomolybdate and add it to the beaker, stir magnetically for a certain period of time to make it dissolve evenly. The ammonium tetrathiomolybdate solution was slowly dropped into 20ml of the prepared PVA solution, and magnetically stirred for several hours to obtain a uniform electrospinning solution. Add the electrospinning solution to the syringe, and in the spinning equipment (such as figure 1 ) for electrospinning. The high-voltage generator is connected to the iron needle, and the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com