Polyurethane microporous elastomer with characteristics of rubber and preparation method thereof

A microporous elastomer, polyurethane technology, used in applications, shoe soles, clothing, etc., can solve the problems of poor low temperature resistance, hydrolysis resistance, low temperature electrical insulation, hydrolysis resistance, and oil resistance that cannot be compared with rubber. , to achieve the effect of low production cost, simple and easy-to-control process, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

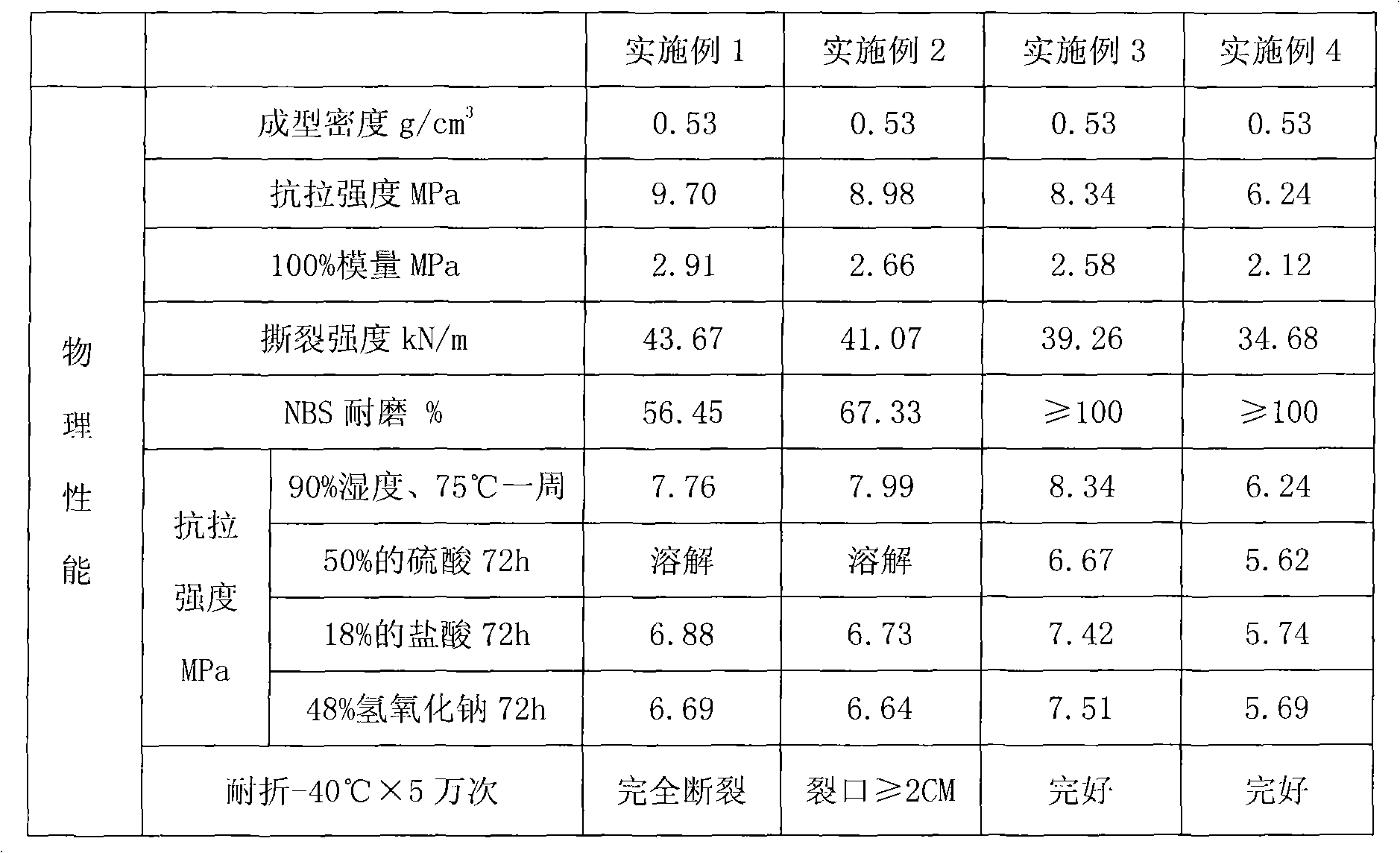

Embodiment 1

[0040] Prepare A component, weigh respectively: 66.67 kilograms of polyester polyol A1, 33.33 kilograms of polyester polyol A2, 3 kilograms of chain extender ethylene glycol, foam stabilizer DC193 (the U.S., produced by Air Products Company, commercially available) 0.4 kg, 0.4 kg of water and 1.3 kg of catalyst triethylenediamine. Put the weighed raw materials in a reaction kettle at 20-50°C, mix them well for 2-4 hours, discharge them, and keep them sealed.

[0041] Prepare component B, weighing: 56.55 kg of diphenylmethane diisocyanate, 2.85 kg of carbodiimide modified polyisocyanate, 24.45 kg of polyester polyol B1, 3.64 kg of polyester polyol B2, 12.47 kg of polyester polyol B3 kg, 2.50 grams of side reaction inhibitor phosphoric acid. Put the weighed raw materials in the reaction kettle, react at 60-80°C for 2-3 hours, remove air bubbles in a vacuum, lower the temperature to 40-45°C, control the free-NCO content to 17-19% by weight, and discharge , sealed and preserved;...

Embodiment 2

[0044] Prepare component A, weigh respectively: polyester polyol A1 60 kg, polyester polyol A2 30 kg, butylated hydroxyl polyol A3 10 kg, chain extender ethylene glycol 3 kg, foam stabilizer DC193 (U.S., air Product company production, commercially available) 0.4 kilograms, water 0.4 kilograms and catalyst triethylenediamine 1.3 kilograms. Put the weighed raw materials in a reaction kettle at 20-50°C, mix them well for 2-4 hours, discharge them, and keep them sealed.

[0045] B component is the same as example 1

Embodiment 3

[0047] Prepare A component, weigh respectively: 46.67 kilograms of polyester polyol A1, 23.33 kilograms of polyester polyol A2, 30 kilograms of butylated hydroxyl polyol A3, 3 kilograms of chain extender ethylene glycol, foam stabilizer DC193 (U.S., air Product company production, commercially available) 0.4 kilograms, water 0.4 kilograms and catalyst triethylenediamine 1.3 kilograms. Put the weighed raw materials in a reaction kettle at 20-50°C, mix them well for 2-4 hours, discharge them, and keep them sealed.

[0048] B component is the same as example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com