Composition based on polypropylene compounds with styrenic based elastomers

A styrenic, polymer technology, used in transportation and packaging, thin material processing, etc., can solve problems such as no processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

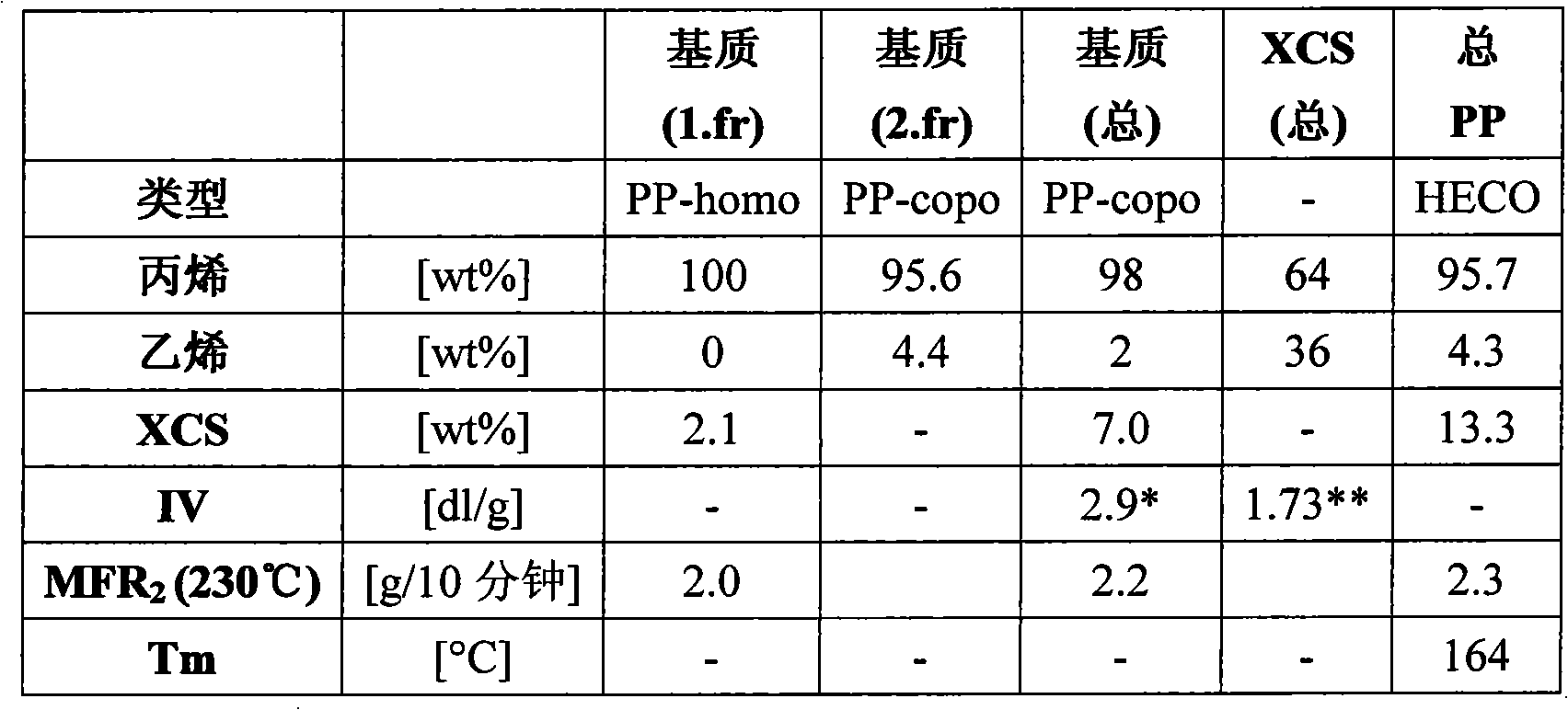

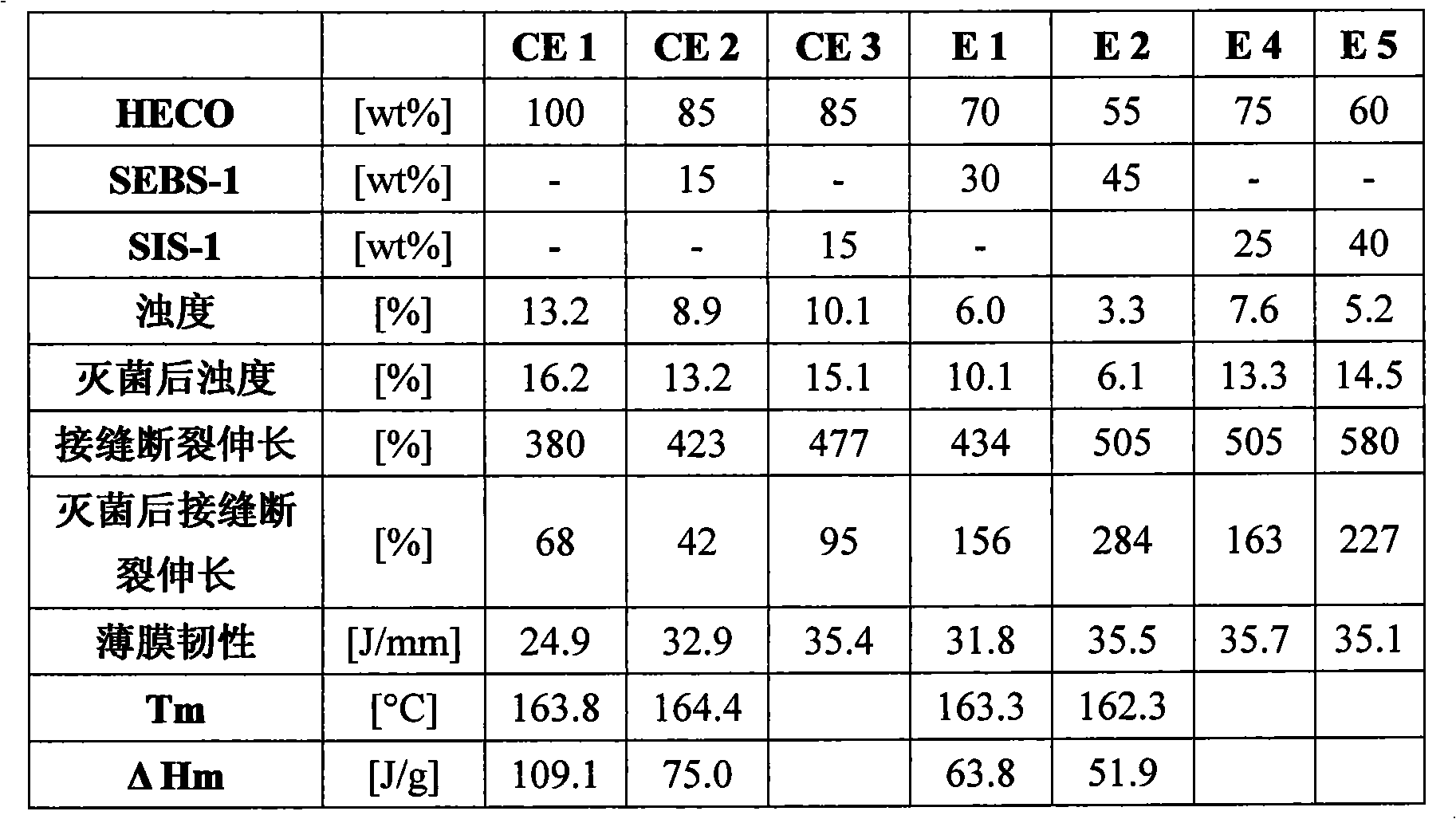

Method used

Image

Examples

Embodiment

[0103] test methods

[0104] 1. Mw, Mn, MWD

[0105] Mw / Mn / MWD is determined by gel permeation chromatography (GPC) according to the following method:

[0106] The weight average molecular weight Mw and the molecular weight distribution (MWD=Mw / Mn, where Mn is the number average molecular weight and Mw is the weight average molecular weight) are determined by a method based on ISO 16014-1:2003 and ISO 16014-4:2003. A Waters Alliance GPCV 2000 equipment equipped with a refractive index detector and an online viscometer was used with 3 TosoHaas TSK-gel columns (GMHXL-HT), and 1,2,4-trichlorobenzene (TCB, with 200mg / L of 2,6-di-tert-butyl-4-methyl-phenol stabilized) was used as a solvent, and 216.5 μL of sample solution was injected at a constant flow rate of 1 mL / min at 145 °C for each analysis. The column set was calibrated using 19 polystyrene (PS) relative standards with narrow molecular weight distributions ranging from 0.5 kg / mol to 11500 kg / mol and a set of well charact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com