Forging hoop

A clamp and semi-circle technology, applied in the direction of sleeve/socket connection, pipe/pipe joint/fitting, passing components, etc., can solve the problems of shrinkage cavity, low yield, small wax mold welding part, etc., and achieve high sealing degree , long service life, flexible assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

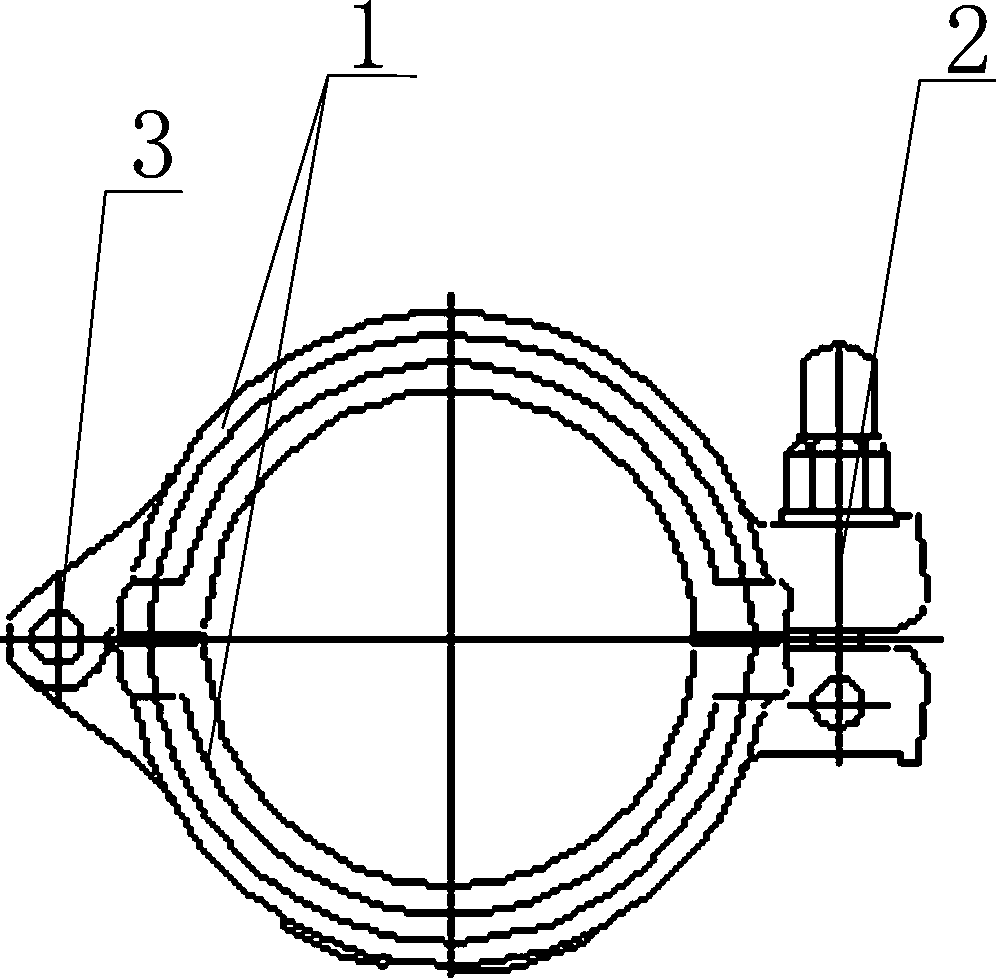

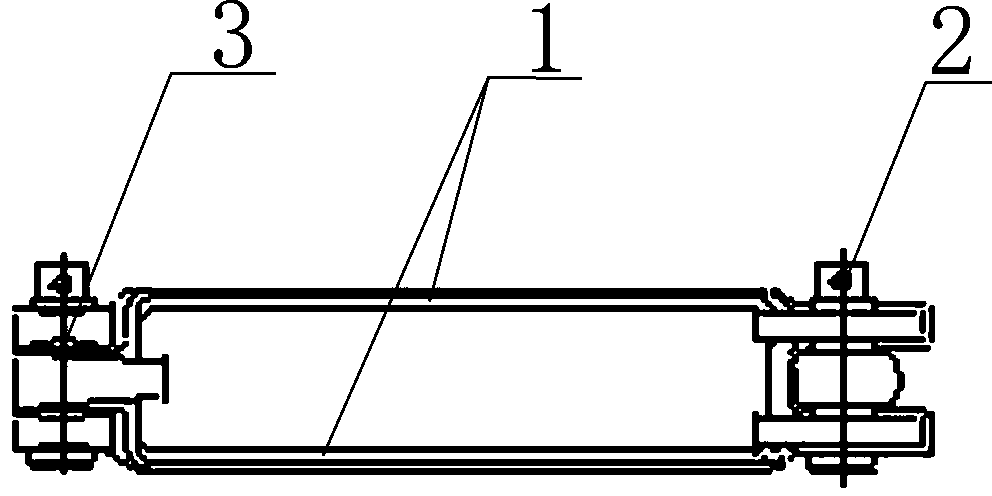

[0010] A forged clamp, two semicircular fixed rings 1 are hinged at one end, and the other ends of the two semicircular fixed rings 1 are fixed by fastening bolts 2 . One end of the two semicircular fixed rings 1 has a hole respectively, and the pin 3 passes through the hole, and the two semicircular fixed rings 1 rotate with the pin 3 as a rotating shaft. The fastening bolt 2 includes a screw rod and a nut. The screw rod passes through the other ends of the two semicircular fixed rings 1 and is fixed by the nuts. The fixed two semicircular fixed rings 1 are hollow circular.

[0011] The forged clamp of the present invention adopts high-quality profiles, is roasted at high temperature, is forged into a blank by a large air hammer, and sent to a fixed steel mold in a large friction press, forged and formed, and then sent to another press to remove flash. After completing the above work, qualified products are quenched and tempered with high-tech heat treatment technology, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com