Display screen maintained from front end

A technology of display screen and display surface, which is applied in the direction of casing/cabinet/drawer parts, instruments, identification devices, etc., which can solve the problems of increased danger, difficulty of installation and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

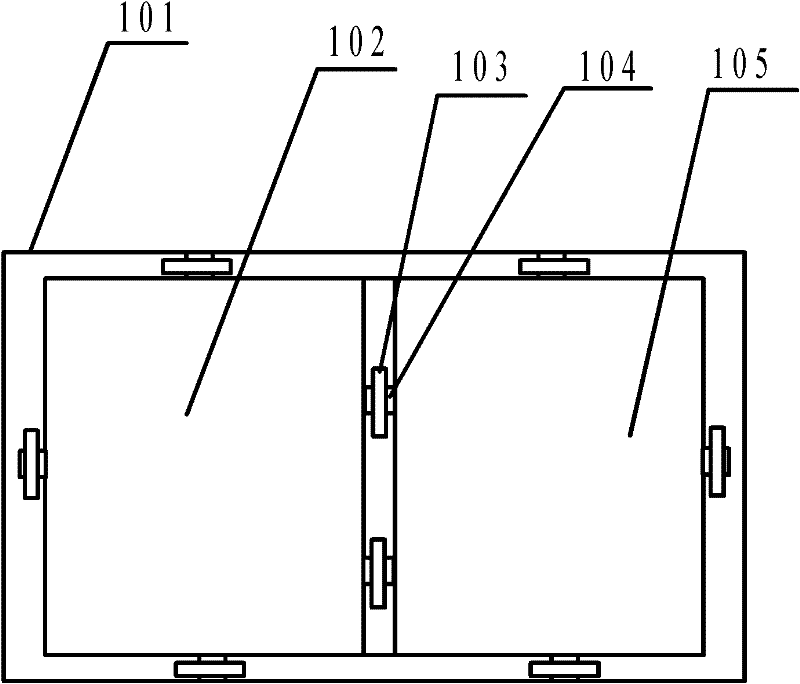

[0019] Such as figure 1 As shown, this embodiment provides a display screen for front-end maintenance. The display screen is an LED display screen, which is generally formed by assembling several modules. Install and disassemble each module on its display surface, so as to perform maintenance work such as installation, repair or replacement of each module.

[0020] Wherein, the display screen includes one or more frames, and two or more modules installed and fixed on each frame, such as, a module 102 and a module 105 are installed on the frame 101, and one of a plurality of LED modules is installed A frame or a plurality of frames can be assembled to form an LED display screen; corresponding to each module, the frame is provided with a mounting position whose shape and size are consistent with the shape and size of the installed module for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com