Vibration damper floor

A technology of floor and hoarding, applied in the direction of floor, building, building structure, etc., can solve the problems such as the inability to change the spring stage elastic supporting force, affecting the stage elastic shock absorption effect, and the spring is not easy to replace. Fatigue failure, flexible and free fastening method, prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

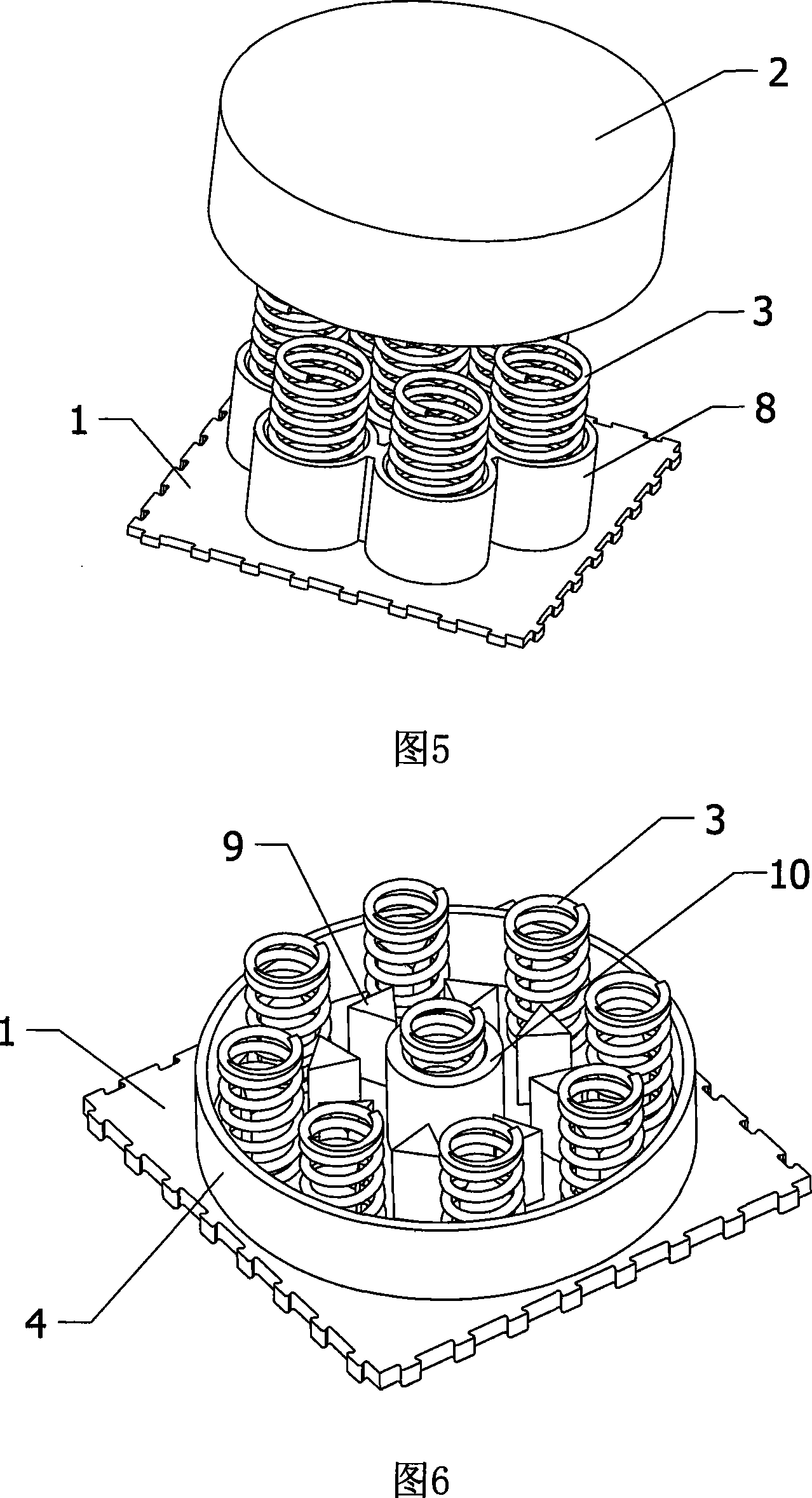

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

[0036] According to Fig. 1 to shown in Fig. 9, shock-absorbing floor of the present invention, it comprises support plate 1, when floor is installed, support plate 1 is installed on the base layer of floor, or when the structure of support plate 1 is relatively thick, can Directly as the base layer of the floor. The support plate 1 is provided with a cover body 2, and the cover body 2 is supported on the support plate 1 by an elastic member 3. The elastic member 3 is mostly a spring, or it can also be other elastic devices. According to the change of the pressure on the cover body 2, Under the action of the elastic force of the elastic member 3 , the cover body 2 can lift back and forth above the support plate 1 . The support plate 1 is provided with a coaming plate 4 matching the cover body 2, and the coaming plate 4 is integrally connected with the support plate 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com