Levofloxacin hydrochloride micropill capsule and preparation method thereof

A technology of levofloxacin hydrochloride and pellet capsules is applied in the field of medicine to achieve the effects of uniform size, small particle size and improving drug stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

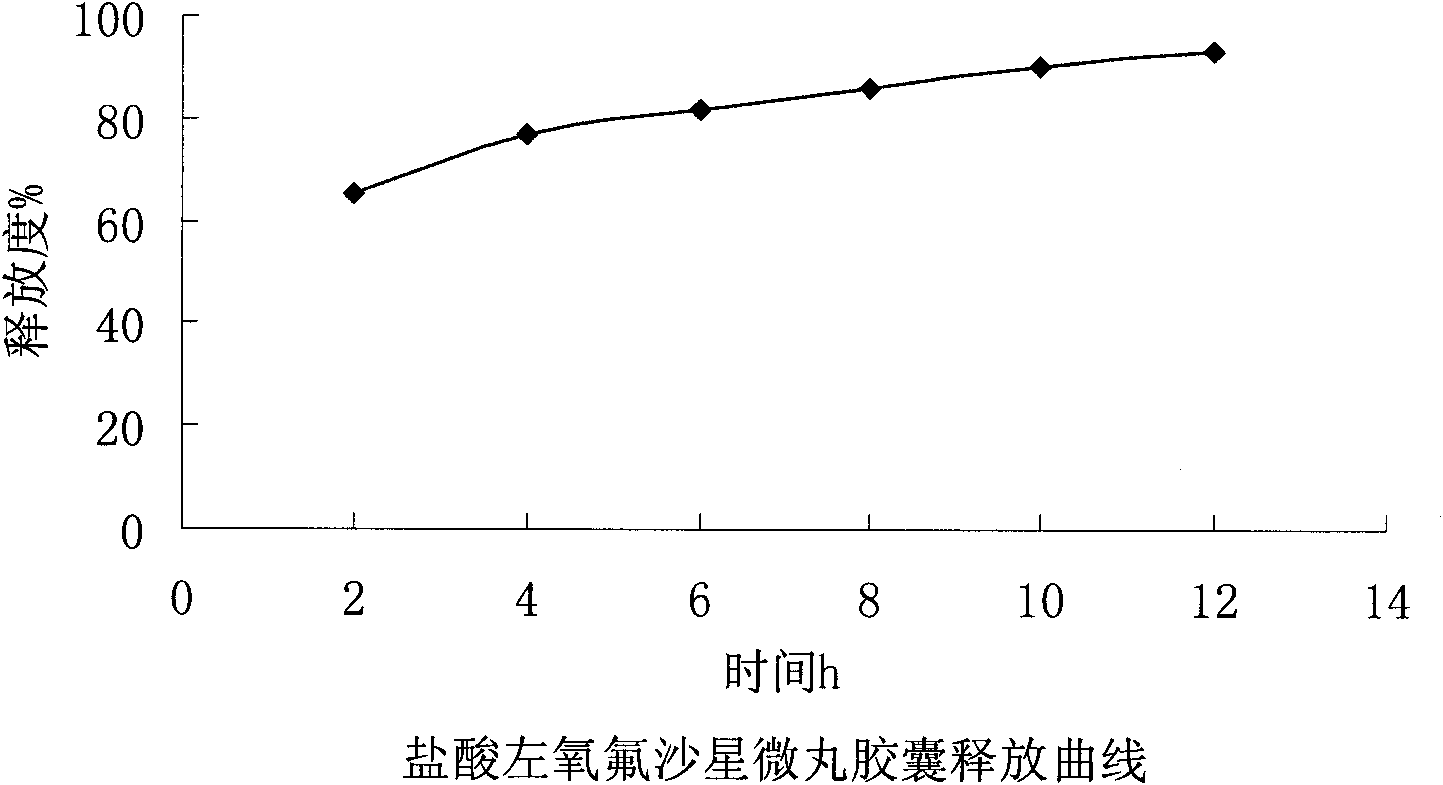

Examples

Embodiment 1

[0032] Embodiment 1: the present embodiment adopts following prescription:

[0033] Levofloxacin hydrochloride (calculated as ofloxacin) 200g

[0034] Sucrose core 153.4g

[0035] povidone k30 18.4g

[0036] Ethylcellulose 11.2g

[0037] Triethyl citrate 2.2g

[0038] Polyethylene glycol 6000 3.3g

[0039] Appropriate amount of talcum powder

[0040]

[0041] Makes 1000 capsules

[0042] Preparation Process:

[0043] (1) Preparation of pill core:

[0044] First, 9.2g of povidone k30 is dissolved in the ethanol solution, 100g of levofloxacin hydrochloride is added in the povidone ethanol solution, and constantly stirred to make it into a uniform suspension; 153.4g of sucrose ball cores are placed in a fluidized bed In the granulator, the above-mentioned homogeneous suspension is sprayed on the surface of the blank sucrose pellet core to prepare pellets, and after all the suspension is added, the pellets are dried and...

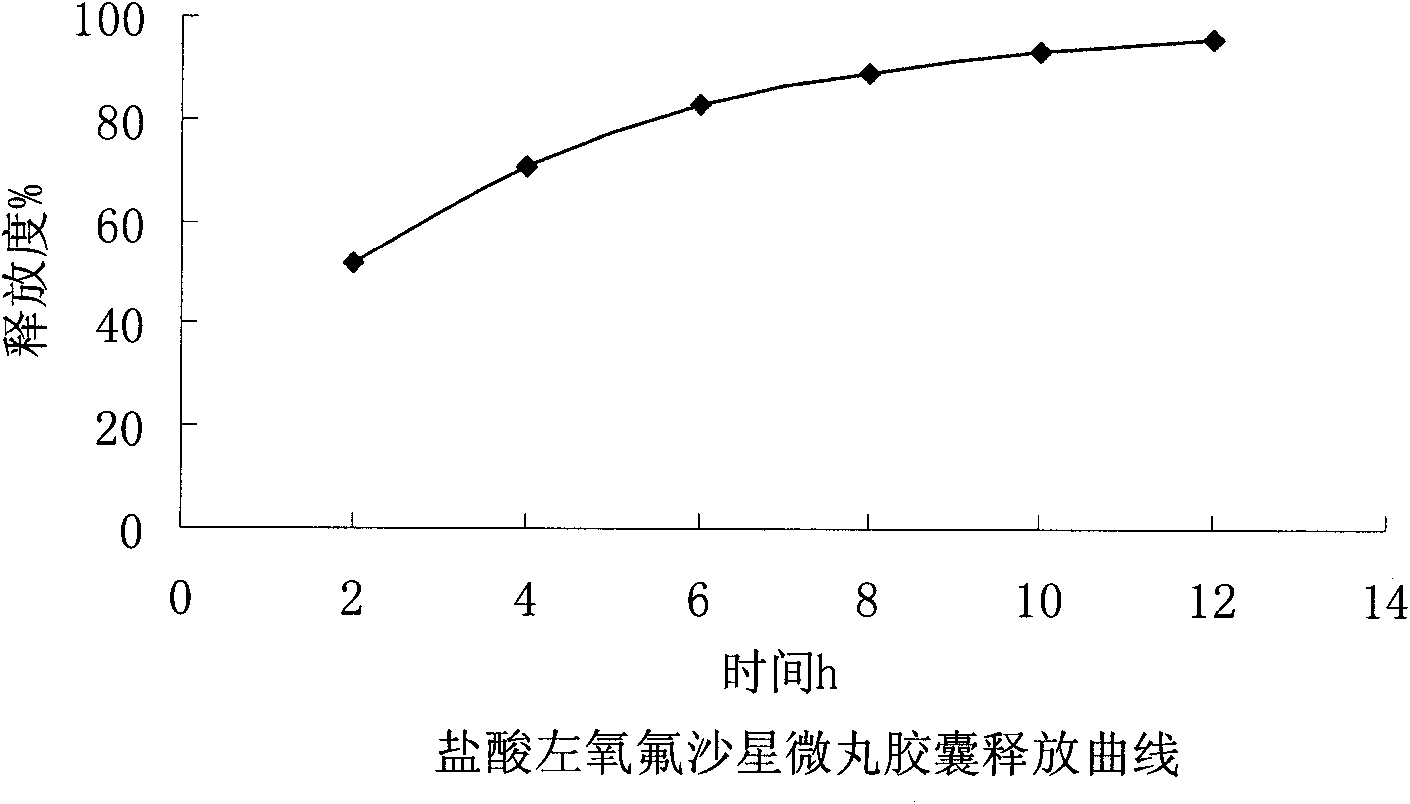

Embodiment 2

[0050] Embodiment 2: the present embodiment adopts following prescription:

[0051] Levofloxacin hydrochloride (calculated as ofloxacin) 400g

[0052] Sucrose core 300g

[0053] povidone k30 36g

[0054] Eudragit NE30D 122g

[0055] Talc powder 36.8g

[0056]

[0057] Makes 1000 capsules

[0058] Preparation Process:

[0059] (1) Preparation of pill core:

[0060] First 21.6g of povidone k30 is dissolved in the ethanol solution, 240g of levofloxacin hydrochloride is added in the povidone ethanol solution, and constantly stirred to make it into a uniform suspension; 300g of sucrose ball cores are placed in a fluidized bed In the granulator, the above-mentioned uniform suspension is sprayed on the surface of the blank sucrose ball core to prepare micro-pills. After all the suspension is added, dry and screen to obtain micro-pills;

[0061] (2) Sustained-release coating layer:

[0062] Dissolve the Eudragit NE30D and talcum powder ...

Embodiment 3

[0066] Embodiment 3: the present embodiment adopts following prescription:

[0067] Levofloxacin hydrochloride (calculated as ofloxacin) 100g

[0069] Hypromellose 20g

[0070] Ethylcellulose 8g

[0071] Triethyl citrate 1.6g

[0072] Macrogol 6000 2.4g

[0073] Appropriate amount of talcum powder

[0074]

[0075] Makes 1000 capsules

[0076] Preparation Process:

[0077] (1) Preparation of pill core:

[0078] First, 8g of hydroxypropylmethylcellulose was dissolved in the ethanol solution, and 40g of levofloxacin hydrochloride was added to the povidone ethanol solution, and kept stirring to make it a uniform suspension; 80g of sucrose ball cores were placed in a fluidized bed In the granulator, the above-mentioned homogeneous suspension is sprayed on the surface of the blank sucrose pellet core to prepare pellets, and after all the suspension is added, the pellets are dried and screened;

[0079]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com