Far infrared heating plate and manufacturing method thereof

A heating plate, far-infrared technology, applied in the direction of ohmic resistance heating, ohmic resistance heating parts, electric heating devices, etc., can solve the problems of low power, easy breakdown, and poor temperature uniformity of far-infrared heating plates, and achieve conductive effect. Good, simple manufacturing process, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

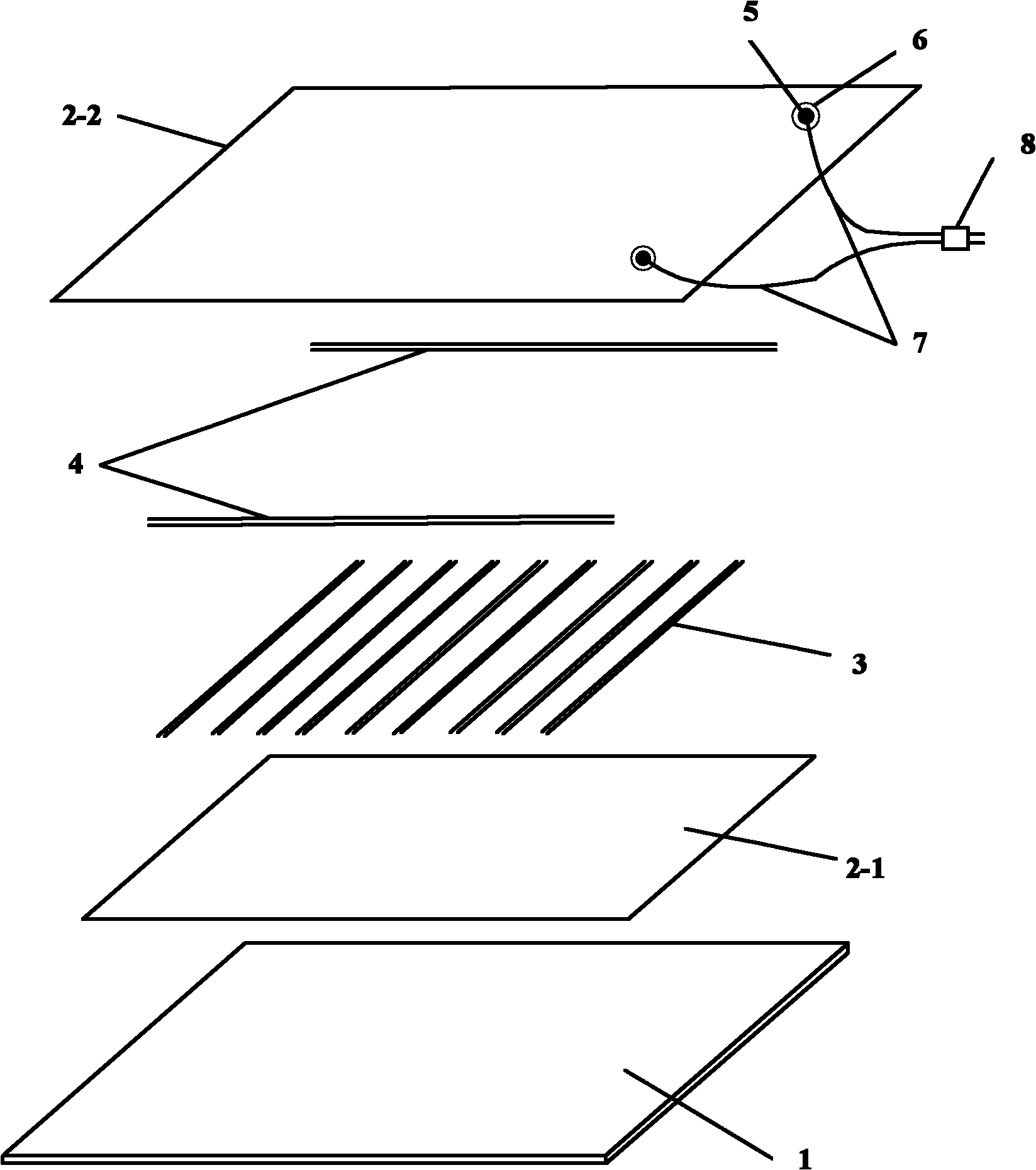

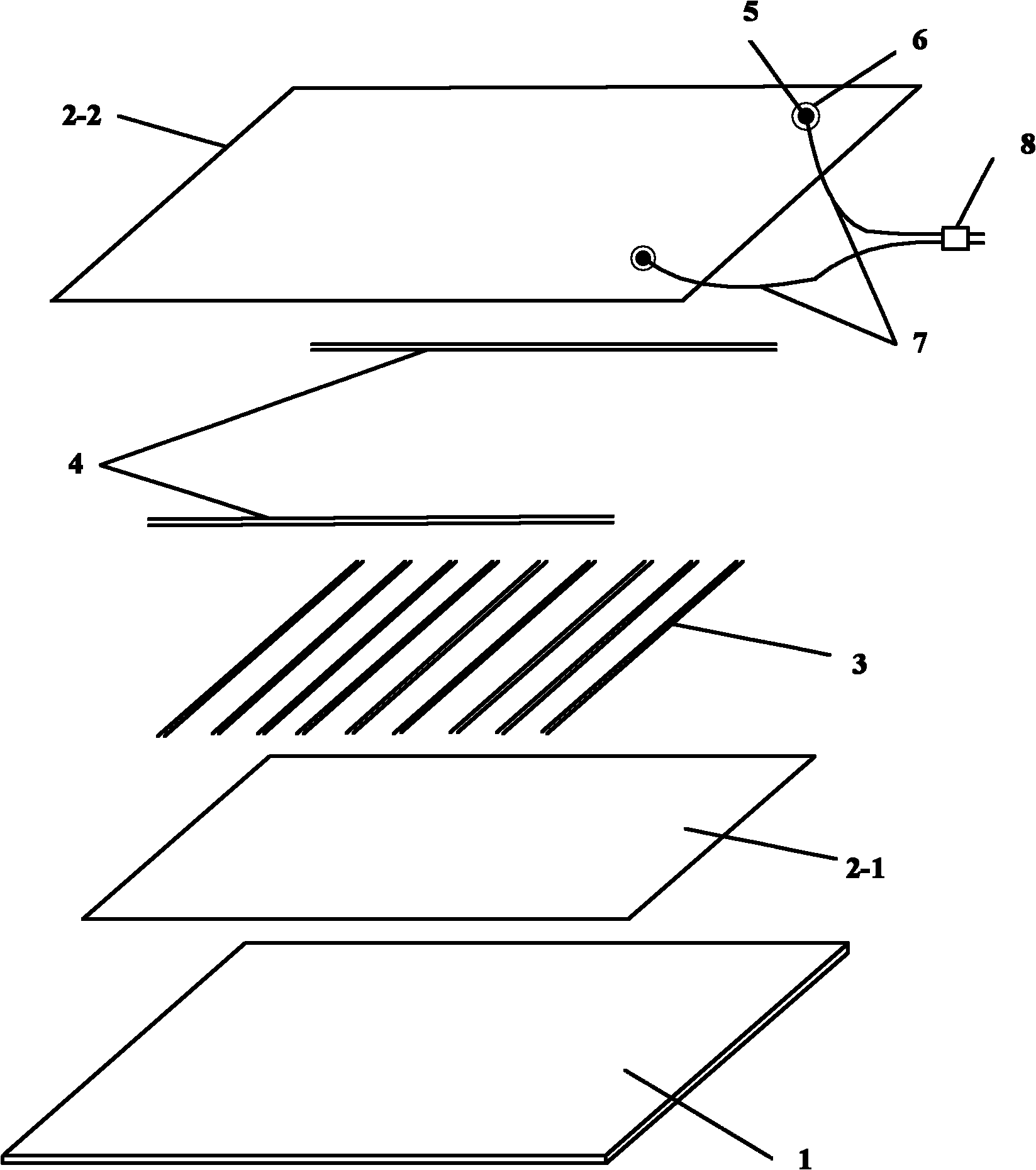

[0026] Such as figure 1 Shown, a kind of far-infrared heating plate comprises aluminum substrate 1, and the top surface of aluminum substrate 1 is attached with first layer polyimide film 2-1, and the top surface of first layer polyimide film 2-1 is printed with multiple A linear infrared paste 3 also includes a copper foil conduction tape 4, a second layer of polyimide film 2-2, and the copper foil conduction tape 4 is pasted on the infrared paste 3 to electrically connect each infrared paste 3 The second layer of polyimide film 2-2 covers the top surface of the first layer of polyimide film 2-1 and covers the copper foil conductive strip 4, and the copper foil conductive strip 4 is electrically connected with the lead wire 7 drawn out.

[0027] The second layer of polyimide film 2-2 has a welding hole 5, the welding hole 5 is provided with an insulating cap 6 covering the welding hole 5, and one end of the wire 7 is fixed in the welding hole 5 by soldering and copper The fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com