Micro-electroforming method based on magnetic force-driven convection effect and device thereof

A technology of convection effect and magnetic field force, applied in the direction of electroforming, electrolysis, etc., can solve the problems of limited mass transfer in liquid phase, achieve the effect of strengthening auxiliary mass transfer, reducing deposition defects, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

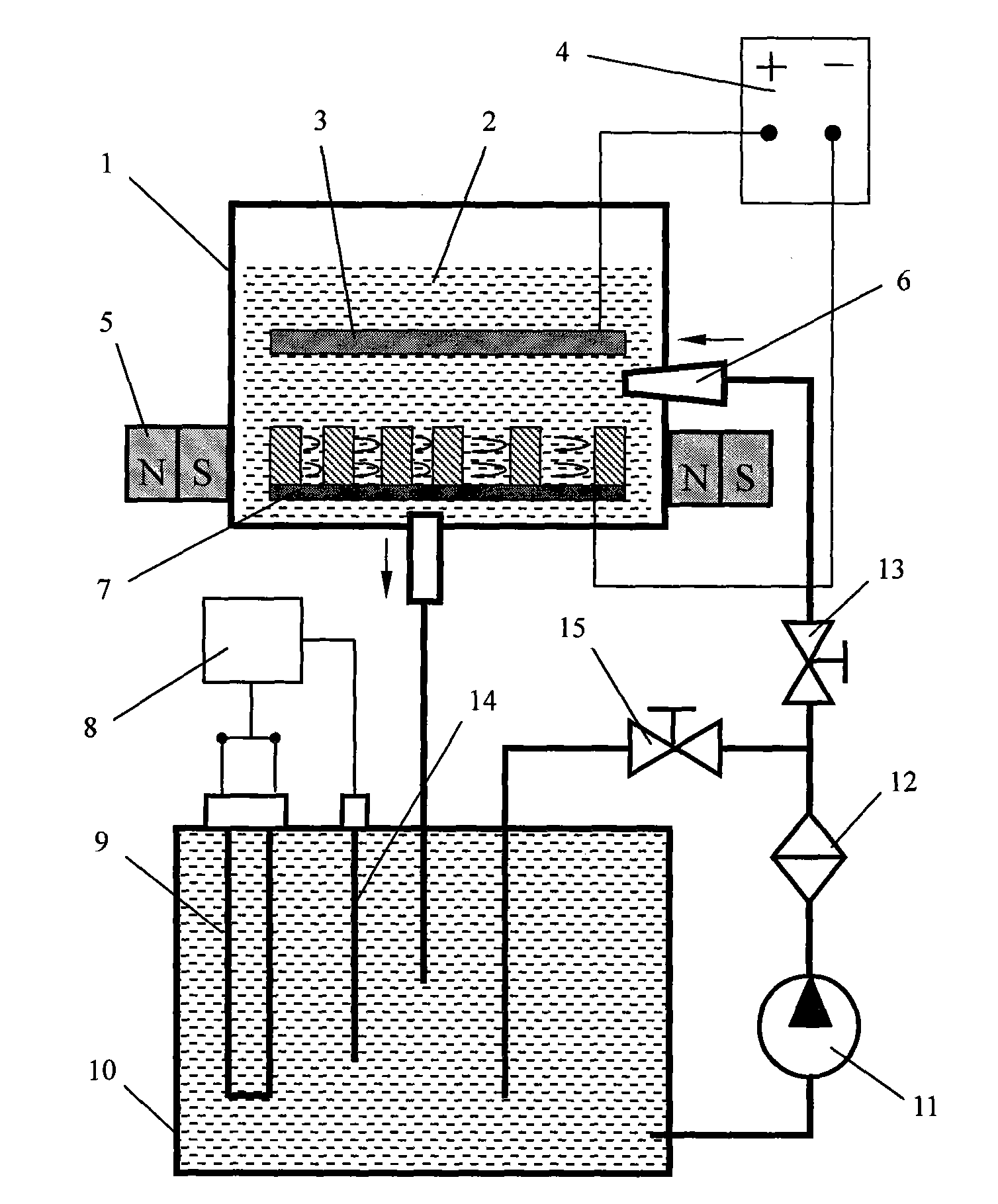

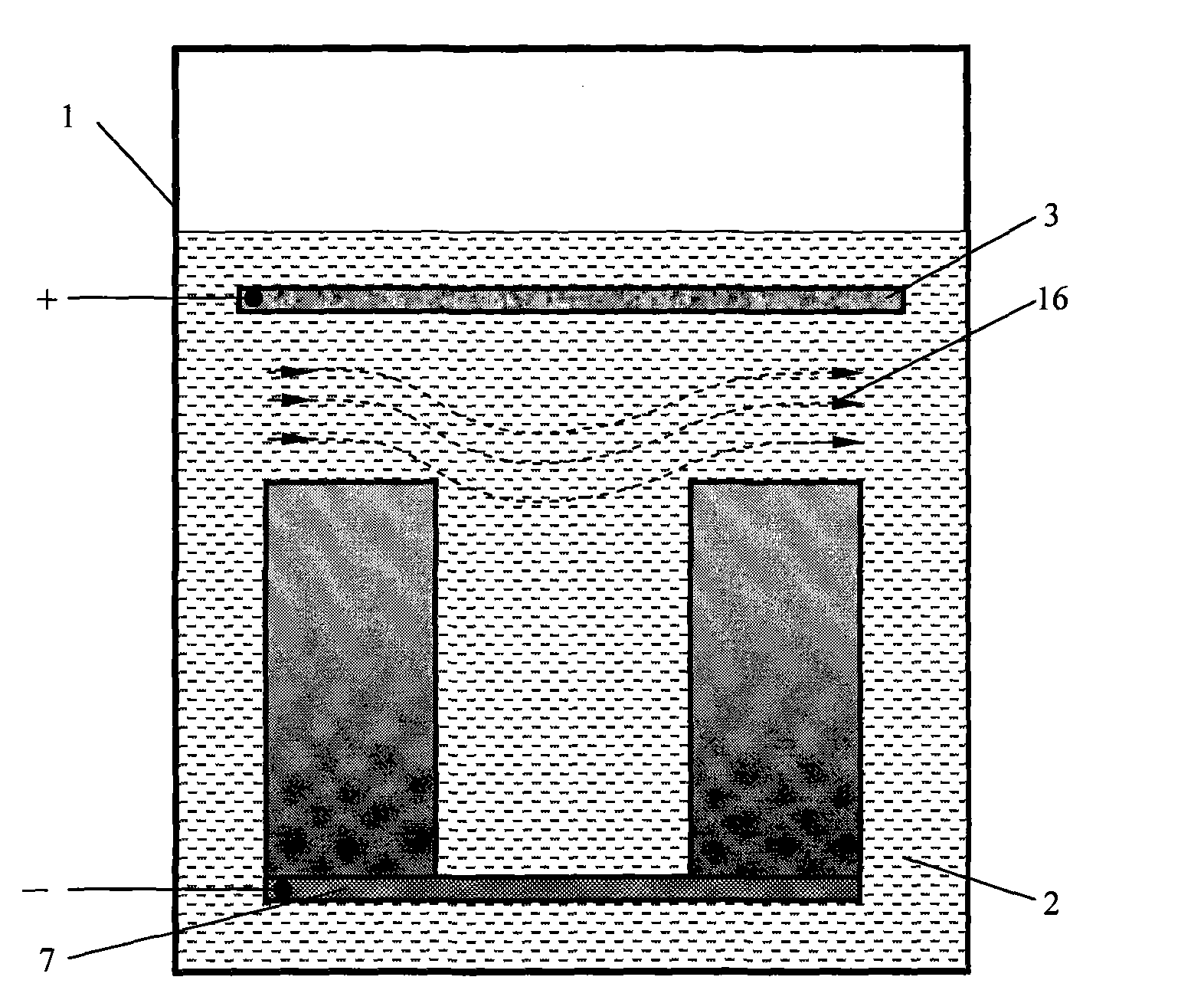

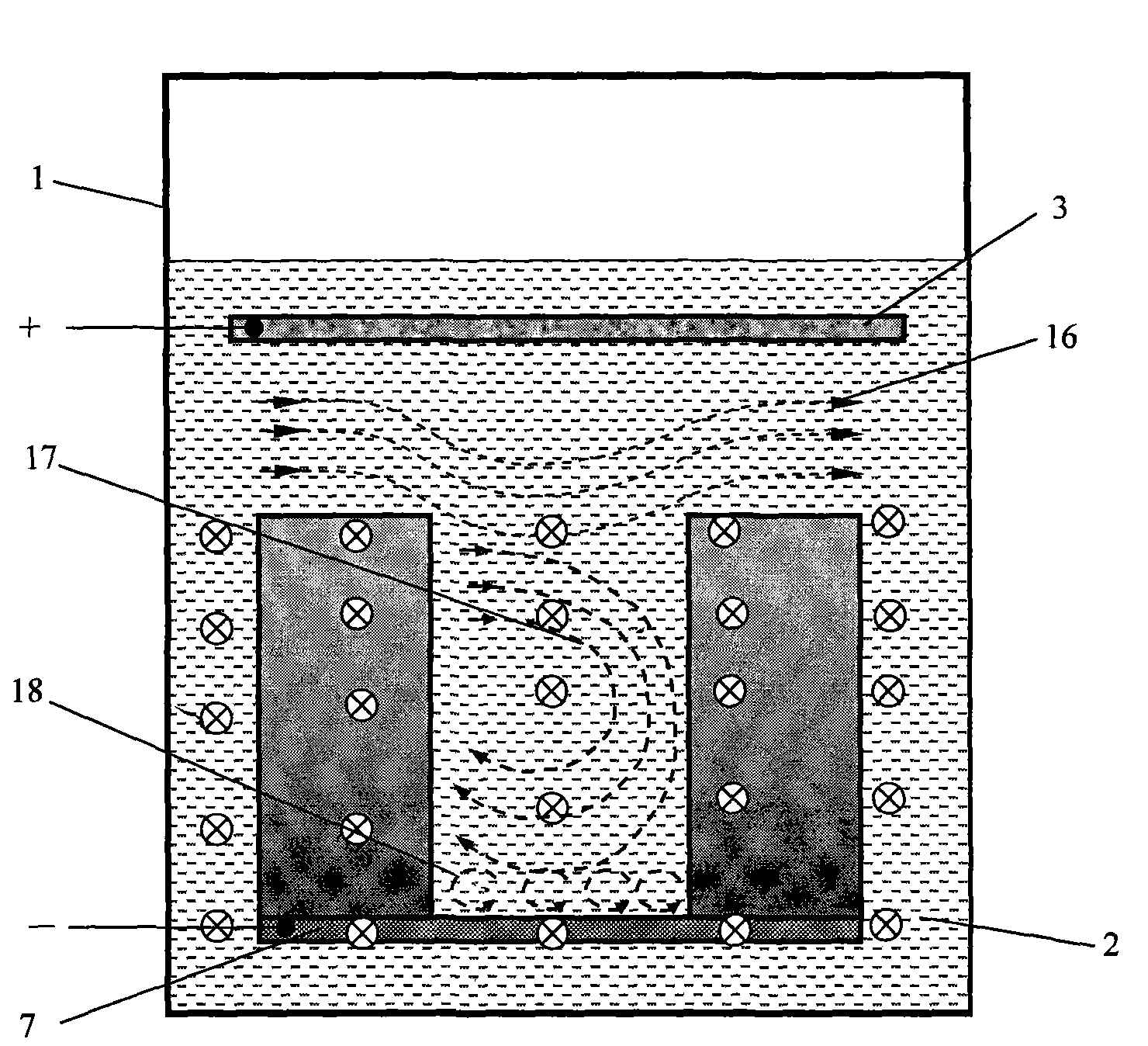

[0025] A micro-electroforming method based on the magnetic field force to drive the convection effect. First, the anode and cathode mandrels are placed in the electroforming tank, and then the electroforming solution is added to the electroforming tank, and the cathode and anode are connected to the power supply. When the mandrel is powered on After the casting layer reaches the specified thickness, the power is cut off, the liquid supply and electroforming are stopped, and the core mold is removed to remove the glue. During the electroforming process, a magnetic field perpendicular to the current direction between the cathode and anode is superimposed on the outside of the core mold.

[0026] The principle of the present invention is as follows: After adding a magnetic field, a large number of charged electromotive particles in the electroforming liquid in the micro-deep hole / groove of the electroforming mandrel are therefore subjected to the strong Lorentz force, and the movem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com