Mechanical and biochemical reaction device applied to coarse pulp of kitchen waste

A technology for kitchen waste and biochemical reaction, applied in the removal of solid waste and other directions, can solve the problems of low efficiency of pulping and hydrolysis and acidification, affecting the stable operation of anaerobic system, increasing the technical difficulty of digester residue treatment, etc., and shortening the stabilization process. , the effect of accelerating the hydrolysis and acidification efficiency, increasing the contact area and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

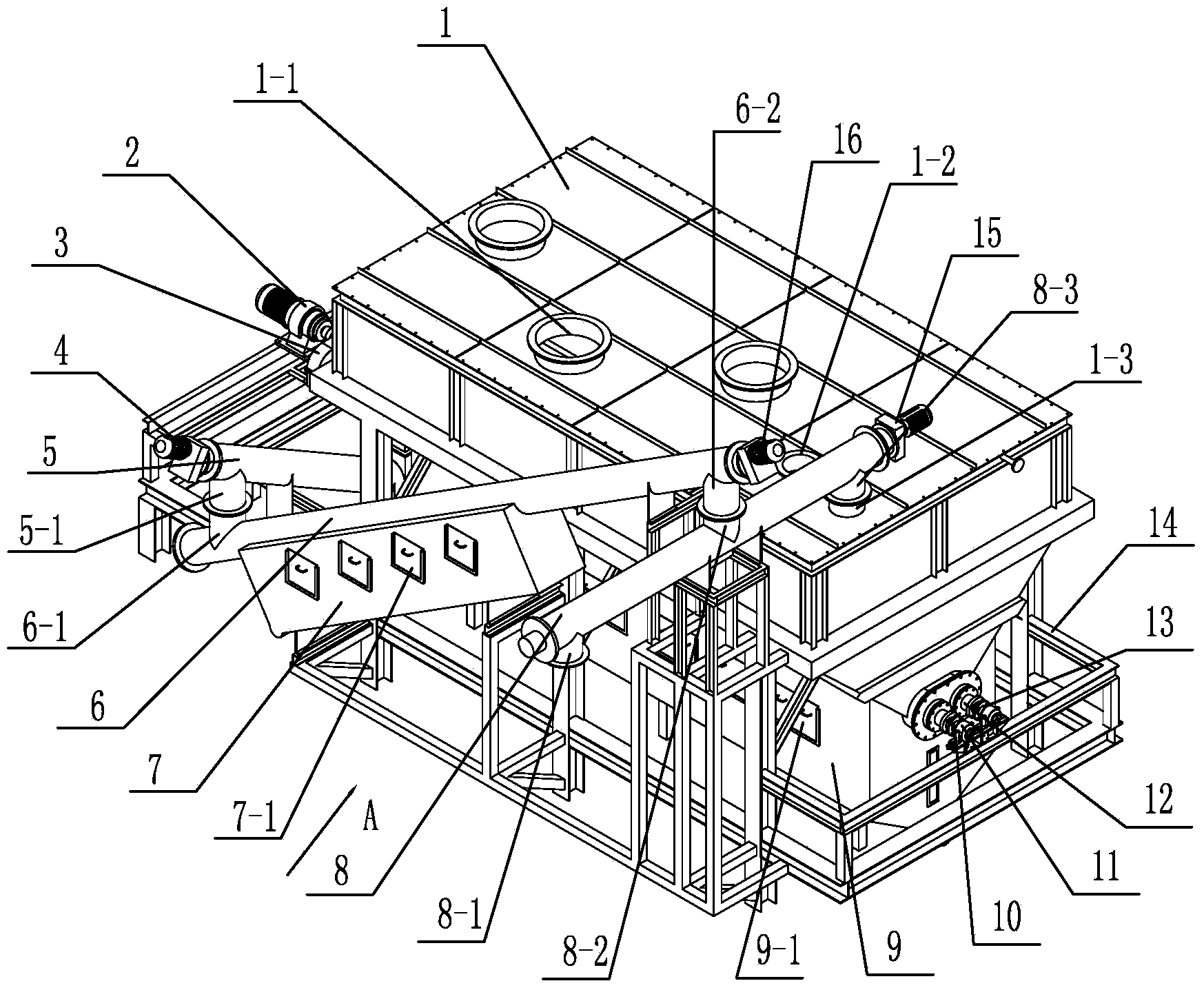

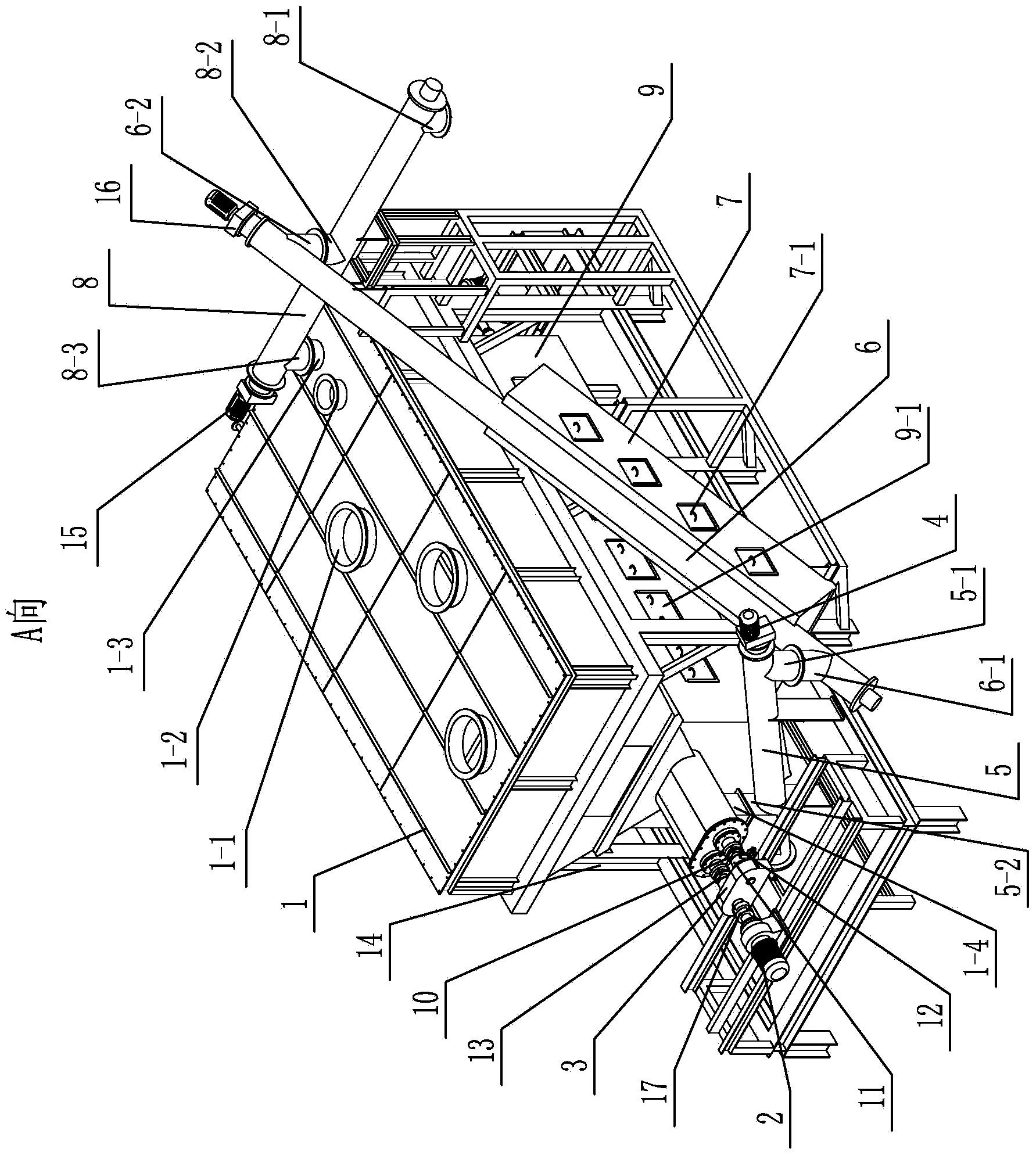

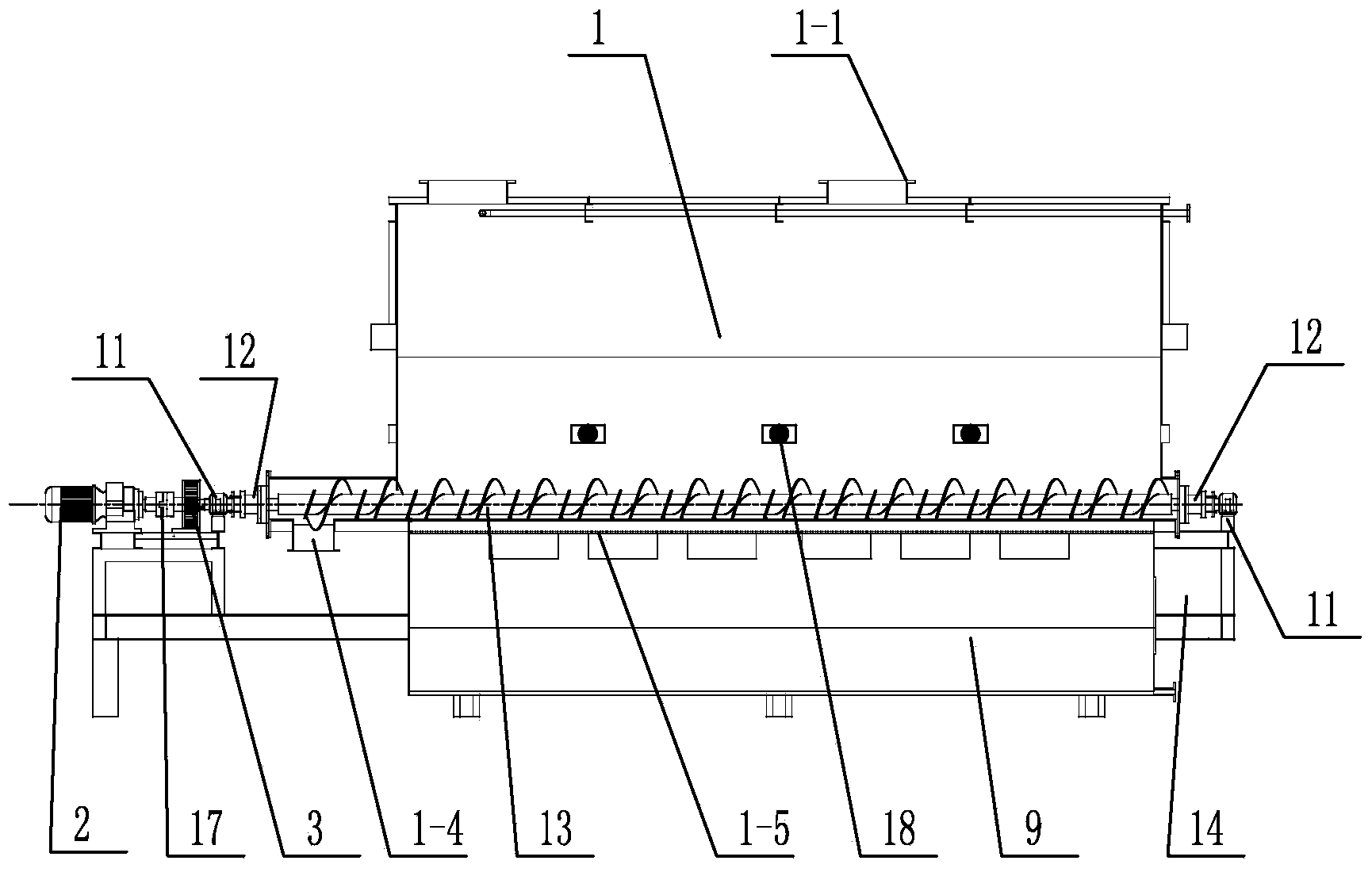

[0019] See Figure 1~4 As shown, the present invention is used for the mechanical biochemical reaction device of kitchen waste coarse slurry, comprises frame 14, the reaction chamber 1 that is installed on the frame 14, liquid collecting tank 9 and biaxial conveying mechanism and three-stage relay material circulation delivery mechanism.

[0020] See Figure 1~4 As shown, the frame 14 of the present invention is a frame structure, through which the reaction chamber 1, the liquid collection tank 9, the biaxial conveying mechanism and the three-stage relay material circulation conveying mechanism are supported. The reaction chamber 1 of the present invention is connected to the liquid collection box 9, and the bottom of the liquid collection box 9 is provided with a liquid outlet, and the organic matter in the coarse slurry is collected by the liquid collection box 9, see figure 1 , 2 Therefore, one of the side plates of the liquid collection tank 9 of the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com