Mine wastewater treatment device and treatment method thereof

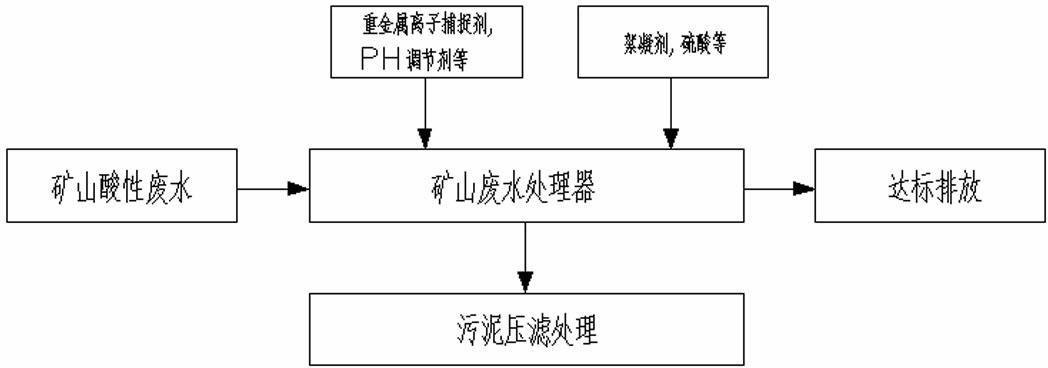

A technology for mine wastewater and processor, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. To achieve the effect of compact equipment structure, convenient operation and management, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

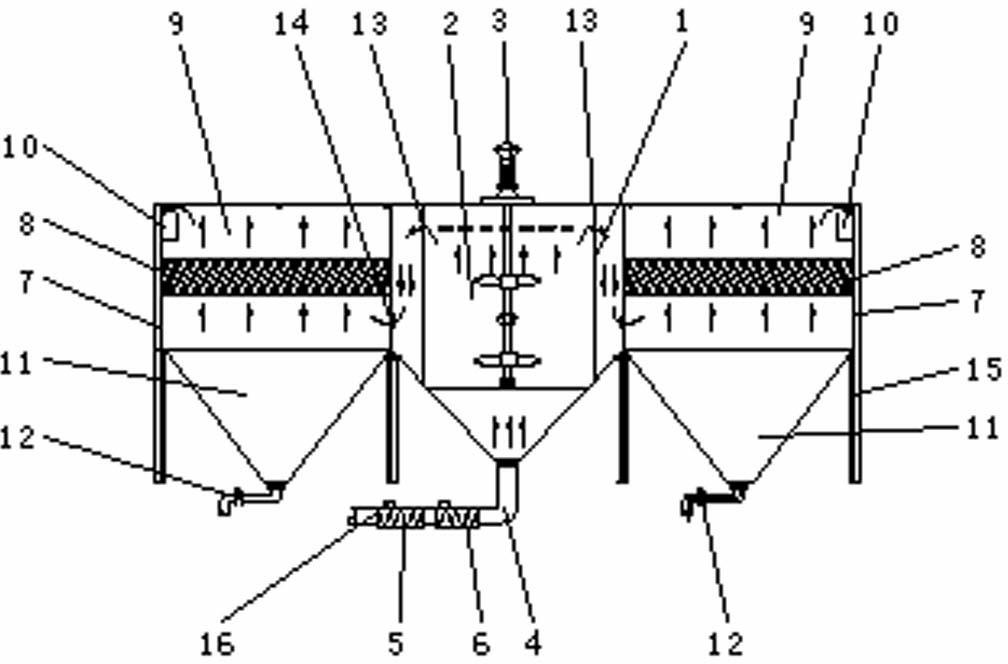

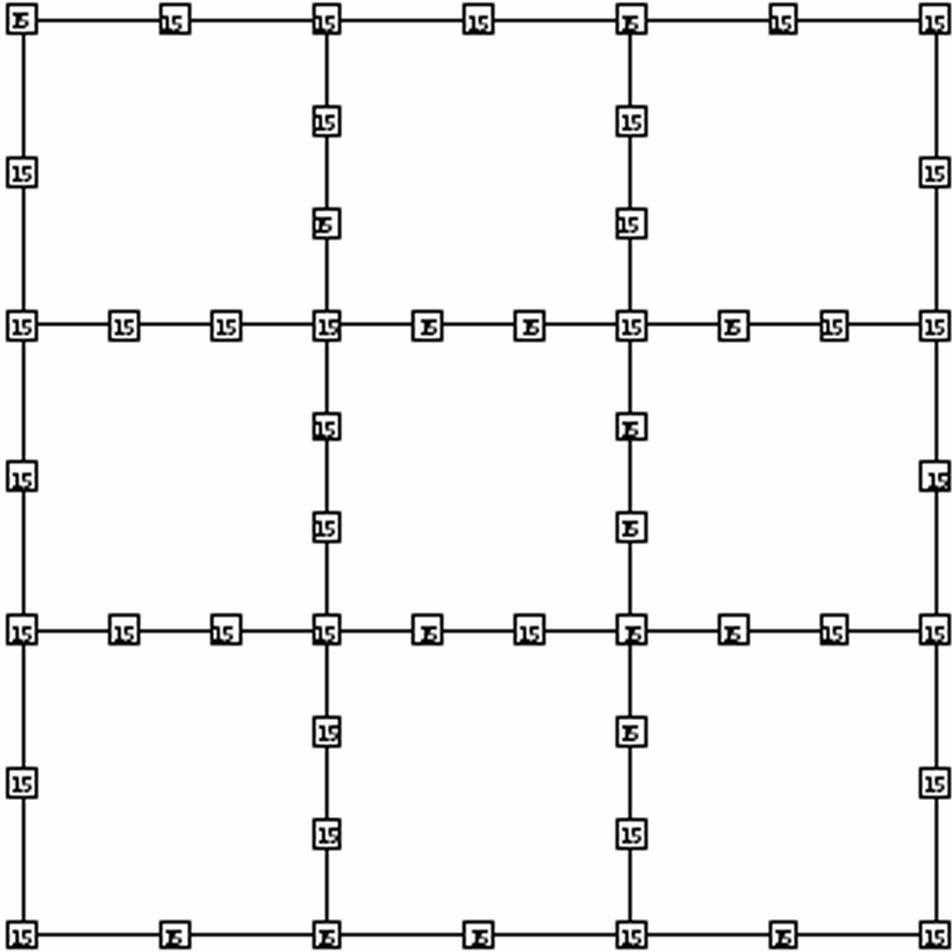

[0024] see Figure 1 to Figure 3 , a kind of mine waste water processor, comprises reactor 1, and the bottom of reactor 1 is communicated with water inlet pipe 4, and in water inlet pipe 4, the first-stage pipeline mixer 5 and the second-stage pipeline made of UPVC are equipped with material The mixer 6, the first-stage pipeline mixer 5 and the second-stage pipeline mixer 6 are spaced at a distance of 2-5 meters, and the pH value regulator is added to the first-stage pipeline mixer through the betting port 16, and the pH value regulator is passed through the betting port 16 Throw heavy metal ion trapping agent in the second-stage pipeline mixer; Agitator 3 is housed in the middle part of reaction chamber 2 of reactor 1, as the supporting power of the agitator 3 of the mine wastewater processor of 600 cubic per hour as processing capacity It is 11kw, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com