Method of adjusting machine tool and machine tool

An adjustment method and machine tool technology, which is applied to the parts of boring machine/drilling machine, milling machine equipment, metal processing machinery parts, etc., can solve the problems of workpiece jumping and incomplete reach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

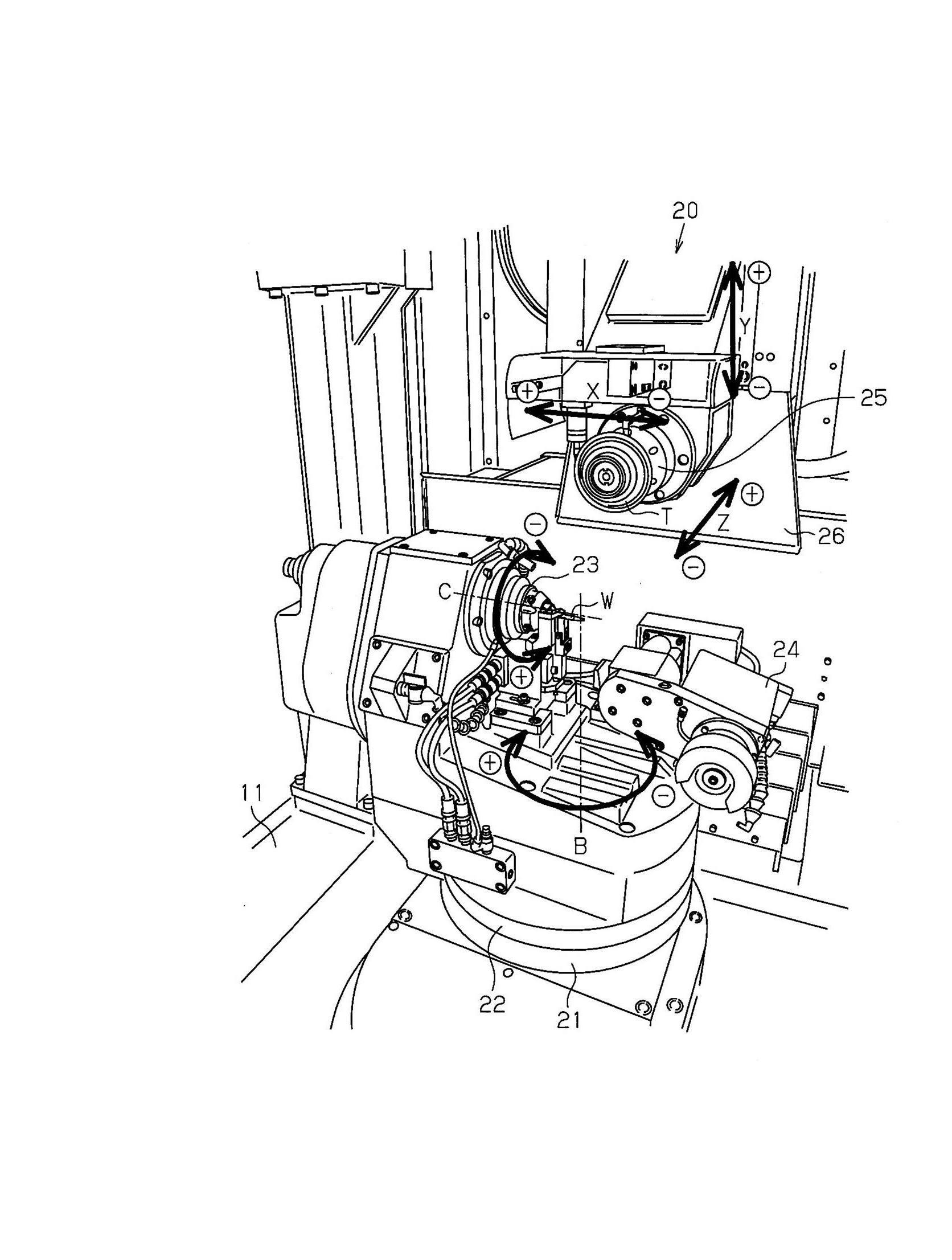

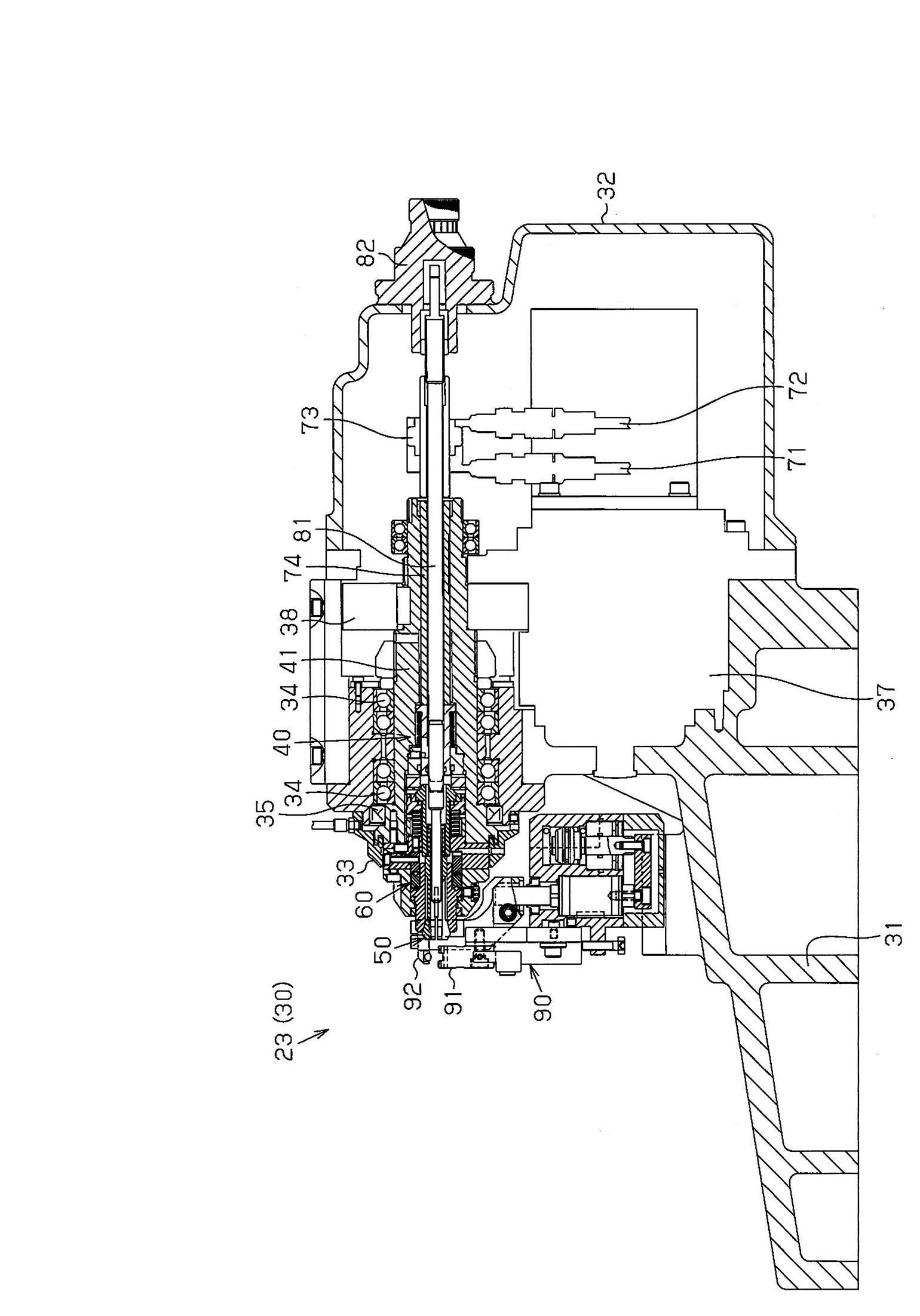

[0072] Figure 1-18 A tool grinder 20 according to a specific embodiment of the invention is described.

[0073] The tool grinder 20 according to the present application is a fully automatic computer numerical control (Computer Numeric Control, CNC) micro-diameter end milling grinder. The tool grinder 20 single-clamping tool fully automatically processes all the steps of end face grinding with small diameter (tool diameter between 0.01 and 2.0mm).

[0074]

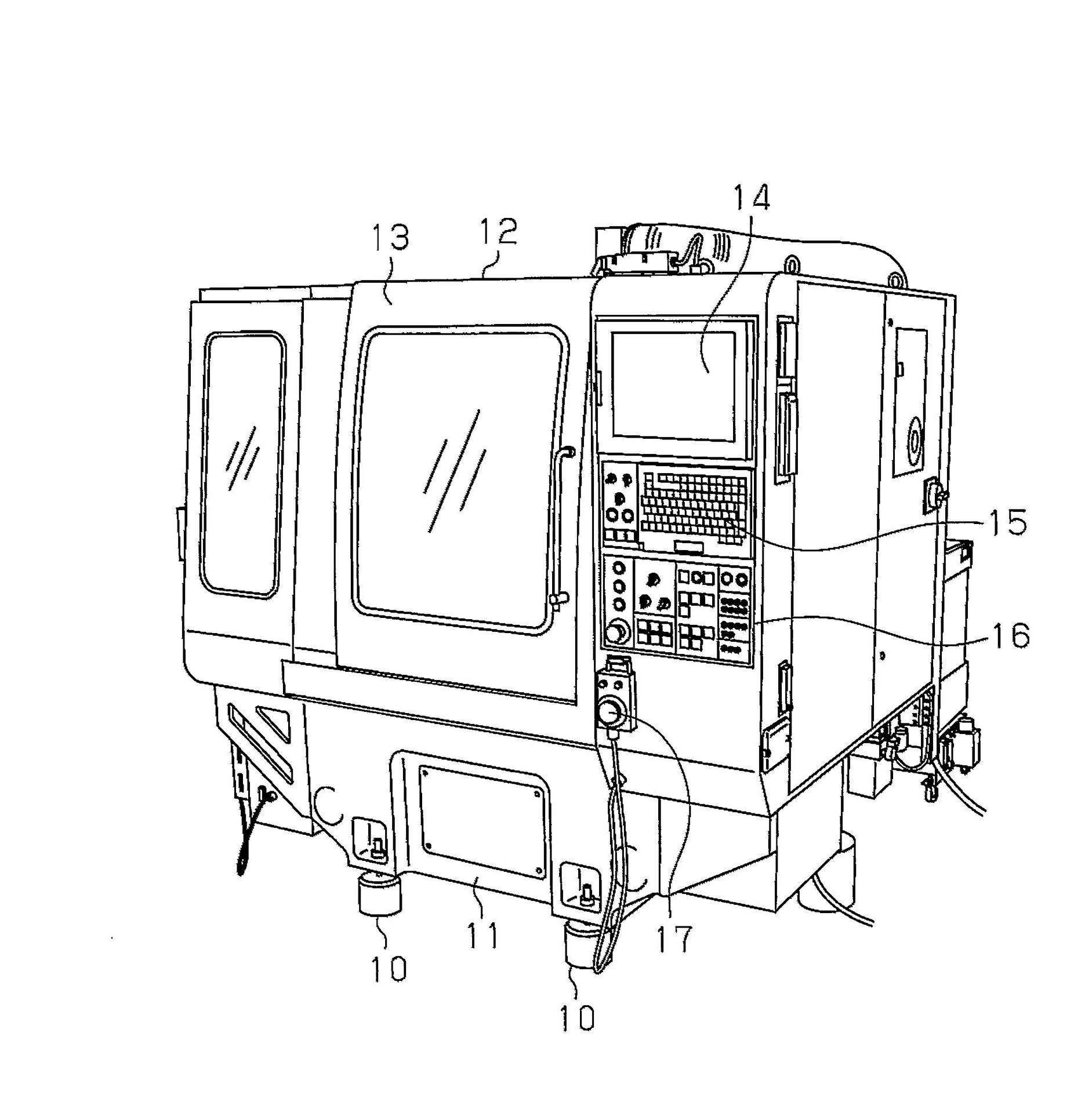

[0075] Such as figure 1 As shown, a tool grinder 20 is housed in an equipment housing 12 whose outer surface forms a box shape and is set on a shelf 11 supported by several bases 10 . The center of the front surface of the equipment housing 12 is provided with a front window 13 which has a window portion and can be selectively opened and closed to isolate the grinding machine 20 installed inside the equipment housing 12 . The front of the equipment casing 12 and the right side of the front window 13 are sequentially e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com