Toughness-increasing polylactic acid composite material and preparation method thereof

A composite material, polylactic acid technology, applied in the field of toughened polylactic acid composite material and its preparation, can solve the problems of resource waste, no technology transformation application, environmental pollution, etc., achieve low cost, good mechanical properties, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

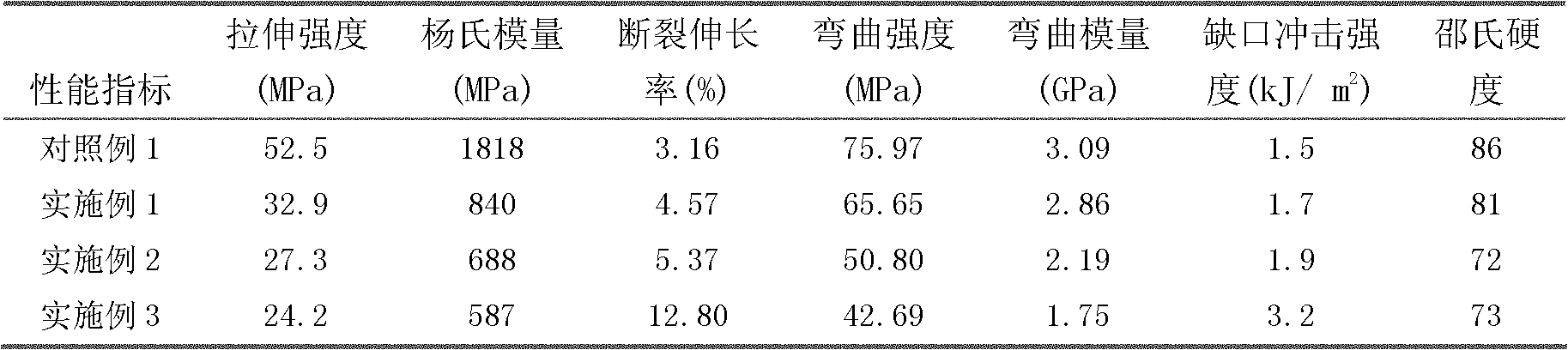

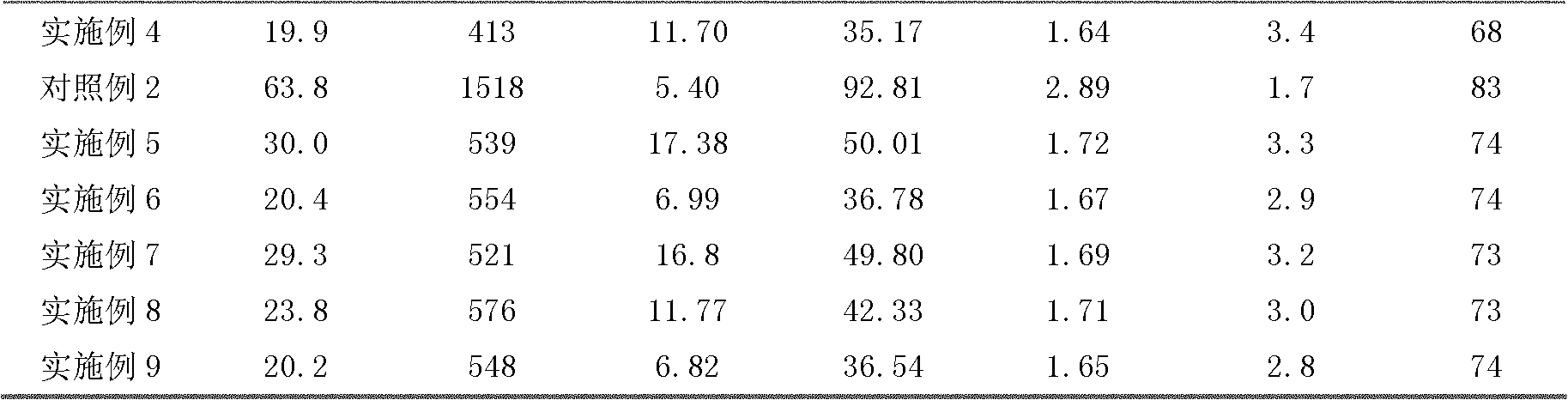

Embodiment 1

[0029] Take 76% (by mass percentage, the same below) polylactic acid (weight average molecular weight 160,000, melting point 150 ° C), 19% cellulose enzymatic lignin, 5% HD800E (Nanjing Huadu Technology Industrial Co., Ltd.) and mix evenly, The mixed material is added into a twin-screw machine, melted and blended, extruded and granulated to form a composite material.

[0030] The temperature setting and processing conditions of each zone of the screw are: the temperature of zones 1 to 7 is 160°C, 165°C, 170°C, 175°C, 180°C, 180°C, 160°C, the temperature of the head is 165°C, and the temperature is 3 to 5 minutes. , the pressure is 12MPa, and the feeding speed is 398rpm.

Embodiment 2

[0032] Take 72% polylactic acid (weight average molecular weight 160,000, melting point 150°C), 18% cellulose enzymatic lignin, 10% HD900V (Nanjing Huadu Technology Industrial Co., Ltd.) and mix evenly, and add the mixture to the twin-screw machine , through melt blending, extruded and granulated into composite materials.

[0033] The temperature setting and processing conditions of each zone of the screw are: the temperature of zones 1 to 7 is 160°C, 165°C, 170°C, 175°C, 180°C, 180°C, 160°C, the temperature of the head is 165°C, and the temperature is 3 to 5 minutes. , the pressure is 12MPa, and the feeding speed is 398rpm.

Embodiment 3

[0035] Take 64% polylactic acid (weight average molecular weight 160,000, melting point 150°C), 16% cellulose enzymatic lignin, 20% HD800E (Nanjing Huadu Technology Industrial Co., Ltd.) and mix evenly, and add the mixture to the twin-screw machine , through melt blending, extruded and granulated into composite materials.

[0036] The temperature setting and processing conditions of each zone of the screw are: the temperature of zones 1 to 7 is 160°C, 165°C, 170°C, 175°C, 180°C, 180°C, 160°C, the temperature of the head is 165°C, and the temperature is 3 to 5 minutes. , the pressure is 12MPa, and the feeding speed is 398rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com