Device with schottky diode integrated in power metal oxide semiconductor (MOS) transistor and manufacturing method thereof

A technology of Schottky diodes and MOS transistors, which is applied in the field of semiconductor integrated circuit manufacturing, can solve the problems of increased chip area, insufficient process flow optimization, and high unit chip cost to achieve improved cross-frequency characteristics, low cost, and occupied area small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0025] The device integrating Schottky diodes in the power MOS transistor mentioned in the present invention, on the basis of the original structure, nests several groups of Schottky contact trenches of specific structure between the gate trenches, the invention point of the main technology As shown in the following table:

[0026]

[0027]

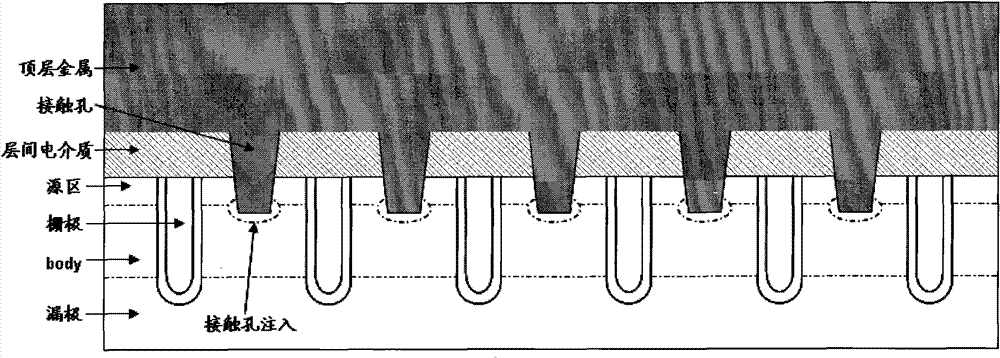

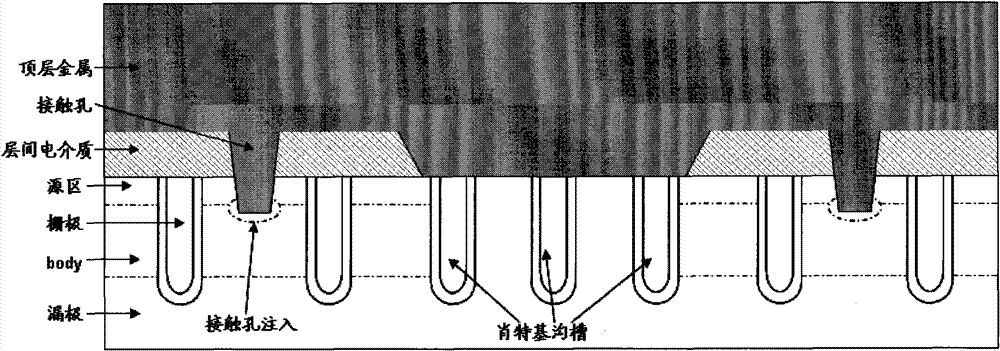

[0028] Compare figure 1 , figure 2 , it can be clearly seen that the structure of the present invention skillfully forms a Schottky diode between the Schottky channels.

[0029] Such as Figure 3-Figure 7 Shown, the manufacturing method of the device of integrated Schottky diode in the power MOS transistor of the present invention, comprises the following steps:

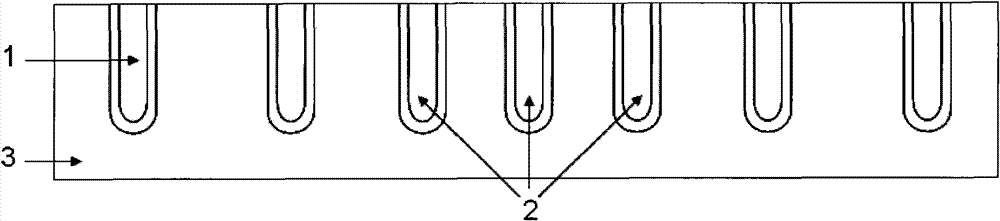

[0030] In the first step, the gate channel 1 and the Schottky channel 2 are exposed and etched on the silicon substrate 3 (the depth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com