Method for qualitatively and quantitatively analyzing hydrocarbon components in aromatics extraction solvent sulfolane

An aromatic hydrocarbon extraction and hydrocarbon component technology, which is applied in the field of analytical chemistry, can solve the problems of inability to guide production in time, unable to measure the content of aromatic hydrocarbons, and the operation is not simple enough, and achieves the effects of shortening time consumption, simple operation and good accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 Qualitative analysis of the hydrocarbon components in the aromatics extraction solvent sulfolane by GC / MS

[0042] The chromatographic conditions are:

[0043] Chromatographic column: non-polar capillary column, 30m×0.25mm,

[0044] Carrier gas: high purity helium,

[0045] Head pressure: 90-100kPa,

[0046] Injection port temperature: 220-250°C,

[0047] Column temperature: the initial temperature is 35°C, the temperature is raised to 50-60°C at 2-4°C / min, and then the temperature is raised to 200-250°C at 35-40°C / min, and kept for 2-5min.

[0048] Injection volume: 0.2-1μL.

[0049] Mass Spectrometry Conditions:

[0050] Interface temperature: 230-250°C,

[0051] Ionization method: electron ionization (EI),

[0052] Electron energy: 70eV,

[0053] Detector voltage: 1.5-1.8kV.

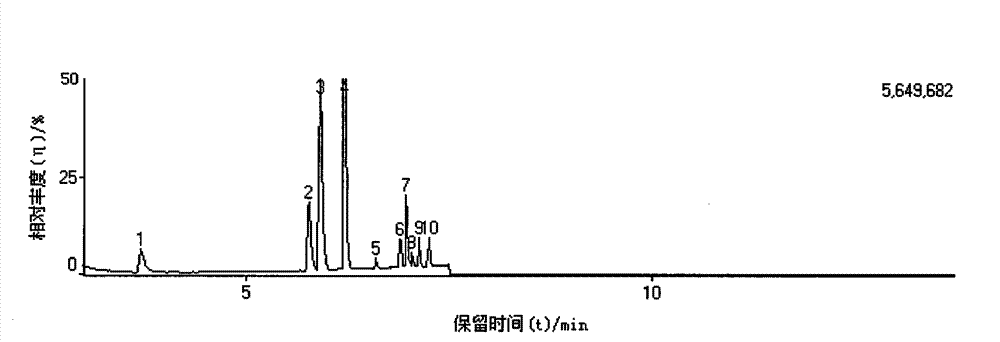

[0054] Direct sample analysis on GC / MS instrument, figure 1 It is a typical sulfolane solvent SCAN analysis total ion chromatogram, according to No. 1 peak, No. 2 peak, No. ...

Embodiment 2

[0055] The mensuration of each hydrocarbon component relative volume correction factor in embodiment 2 sulfolane

[0056] Chromatographic conditions and mass spectrometry conditions are the same as in Example 1.

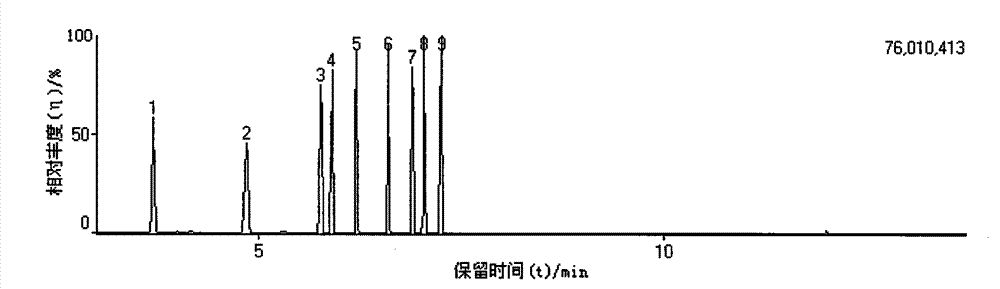

[0057]In a 10mL volumetric flask, add 4 μL each of toluene, n-octane, ethylbenzene, o-xylene, cumene, n-propylbenzene, 1,3,5-trimethylbenzene, 1,2,4-trimethylbenzene, m- 2 μL each of xylene and p-xylene, dilute to 10 mL with analytical grade acetone, and prepare a standard solution, including toluene, n-octane, ethylbenzene, o-xylene, cumene, n-propylbenzene, 1, 3, 5 - The concentrations of trimethylbenzene and 1,2,4-trimethylbenzene are 400 μL / L, and the concentrations of m-xylene and p-xylene are 200 μL / L. The standard solution was directly injected on the GC / MS instrument and repeated 6 times. The SCAN analysis total ion chromatogram of this standard solution is shown in figure 2 . Among them, peak No. 1 is toluene, peak No. 2 is n-octane, peak No. 3 is ethyl...

Embodiment 3

[0064] Example 3 investigates the precision and accuracy of the inventive method to measure the content of each hydrocarbon component in the aromatics extraction solvent sulfolane

[0065] Chromatographic conditions and mass spectrometry conditions are the same as in Example 1.

[0066] Preparation of mother liquor: In a 10mL volumetric flask, add 10μL each of toluene, ethylbenzene, o-xylene, cumene, n-propylbenzene, 1,3,5-trimethylbenzene, and 1,2,4-trimethylbenzene, Then add 5 μL each of m-xylene and p-xylene, and dilute to 10 mL with acetone. The volume concentration of toluene, ethylbenzene, o-xylene, isopropylbenzene, n-propylbenzene, 1,3,5-trimethylbenzene, 1,2,4-trimethylbenzene is 1000 μL / L, m-xylene, p-xylene The volume concentration was 500 μL / L.

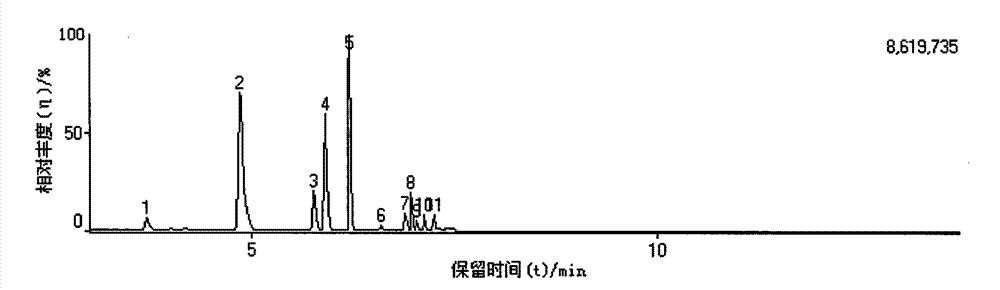

[0067] Preparation of samples with low hydrocarbon concentration: Add 0.5mL of mother liquor to a 10mL volumetric flask, and dilute to 10mL with sulfolane solvent from the No. 2 joint production site of Jiujiang Branch C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com