Biodegradable cigarette fiber material and cigarette filter

A biodegradable, fiber material technology, applied in the direction of smoke oil filter, fiber treatment, fiber chemical characteristics, etc., can solve the problems of high brittleness, poor heat resistance, low thermal deformation temperature, etc., and achieve the effect of good biodegradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

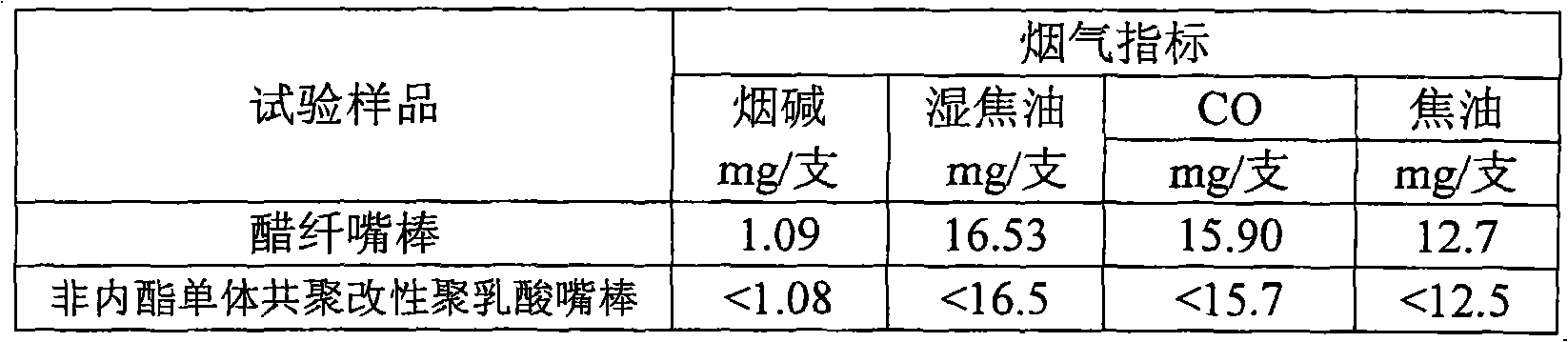

Examples

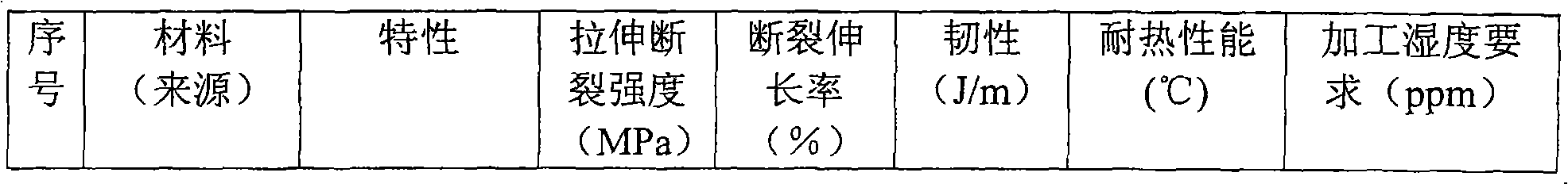

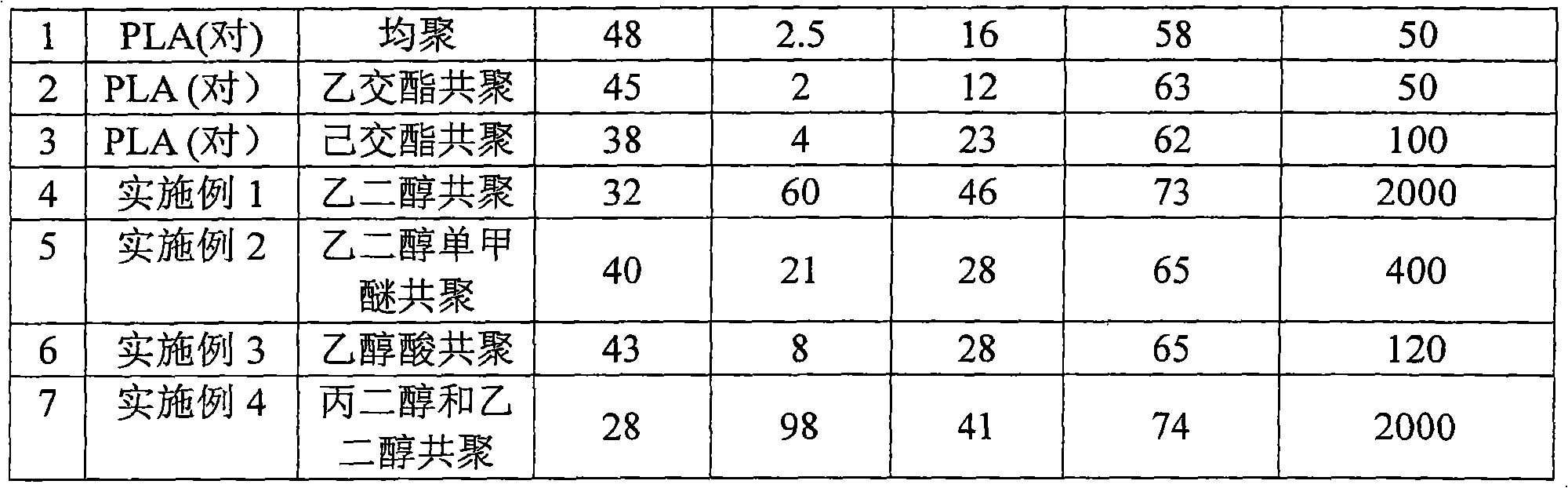

Embodiment 1

[0055] Take by weighing 100 kilograms of weight-average molecular weight of (15 ± 1) ten thousand, dispersion index is 1.5, and the non-lactone monomer copolymerization modified polystyrene containing 15% (number of chain segments) randomly distributed ethylene glycol chain segments on the molecular chain Lactic acid is the base resin, and the ratio by weight of modified polylactic acid: triphenyl phosphate: antioxidant 1222 (3,5-di-tert-butyl-4-hydroxyphenyl diethyl phosphate) is 97: 2.5: Weigh the raw material at a ratio of 0.5, dry it in an oven at 55°C for 5 hours, stir it evenly in a high-speed mixer, and then extrude and granulate it on a Φ57 twin-screw extruder with an aspect ratio of 32. The temperature of the screw barrel is set as: The first stage is 190°C, the second stage is 195°C, the third stage is 200°C, the fourth stage is 200°C, and the fifth stage is 190°C. The extruded strips are pelletized with a pelletizer, dried on-line with hot air, and packaged , to obt...

Embodiment 2

[0065] Select 99.6 kg weight average molecular weight of (10 ± 1) million, dispersion index of 1.2, and the molecular chain contains 1% (number of chain segments) randomly distributed ethylene glycol monomethyl ether chain unit copolymerization non-lactone monomer copolymerization Modified polylactic acid is used as the base resin, and 0.4 kg of triphenyl phosphite is dried in an oven at 45°C for 8 hours, and stirred evenly in a high-speed mixer. In an environment with a drying device, the length-to-diameter ratio is Extrude and granulate on the Φ75 twin-screw extruder at 32, the temperature of the screw barrel is set at 160°C for the first stage, 185°C for the second stage, 195°C for the third stage, 200°C for the fourth stage, and 200°C for the fifth stage 195°C. The extruded material strips are pelletized by a pelletizer, dried on-line with hot air, and packaged to obtain the special material for the cigarette holder rod of the present invention.

[0066] The special materia...

Embodiment 3

[0075] It is 300,000 to select the weight-average molecular weight, and the dispersion index is 3.0, and the copolymerization non-lactone monomer copolymerization modified polylactic acid containing 30% (chain number) of glycolic acid chain segments randomly distributed on the molecular chain is the base material resin. After drying in an oven at 50°C for 8 hours, spin on a Φ65 melt spinning machine with a screw length-to-diameter ratio of 28. The first stage of the screw temperature of the spinning machine is set to 190°C, and the second stage is set to 205°C. The third section is set at 220°C, the filter temperature is 200°C, the box temperature is 205°C, and the straight pipe temperature is 205°C. After being sprayed out from a spinneret with a specification of 1250×1, it is cooled by side blowing of dry air with a temperature range of 20 to 40°C.

[0076] The tow after above-mentioned cooling is coated with oil in the oiling tank, and the oiling in the oiling tank is the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circumference | aaaaa | aaaaa |

| Draw resistance | aaaaa | aaaaa |

| Draw resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com