Hypericin purifying method

A technology of hypericin and purification method, applied in quinone separation/purification, organic chemistry, etc., can solve the problems of low purity of hypericin, complicated process, and pollution of finished products, and achieve high mechanical strength and good chemical stability , High recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

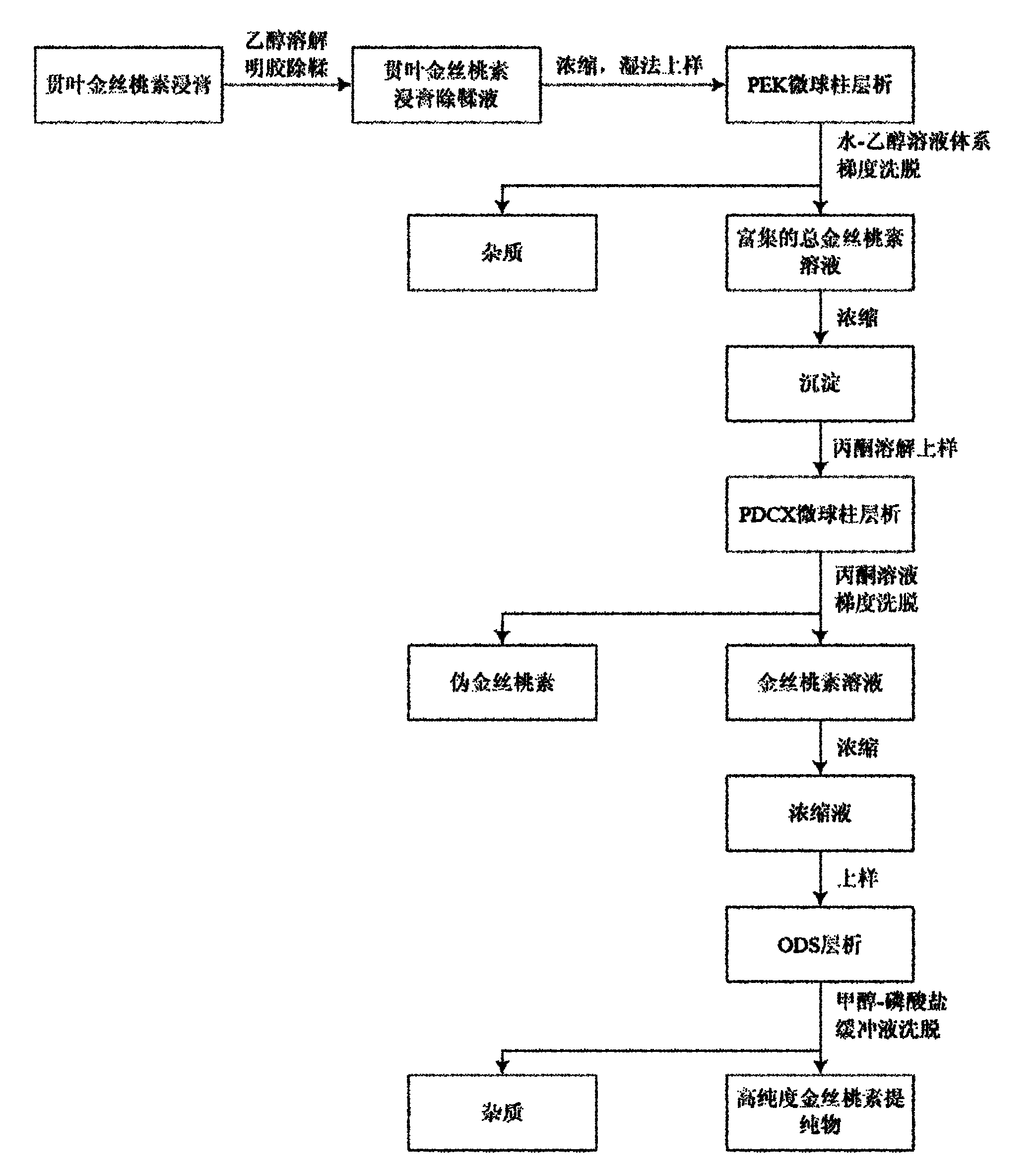

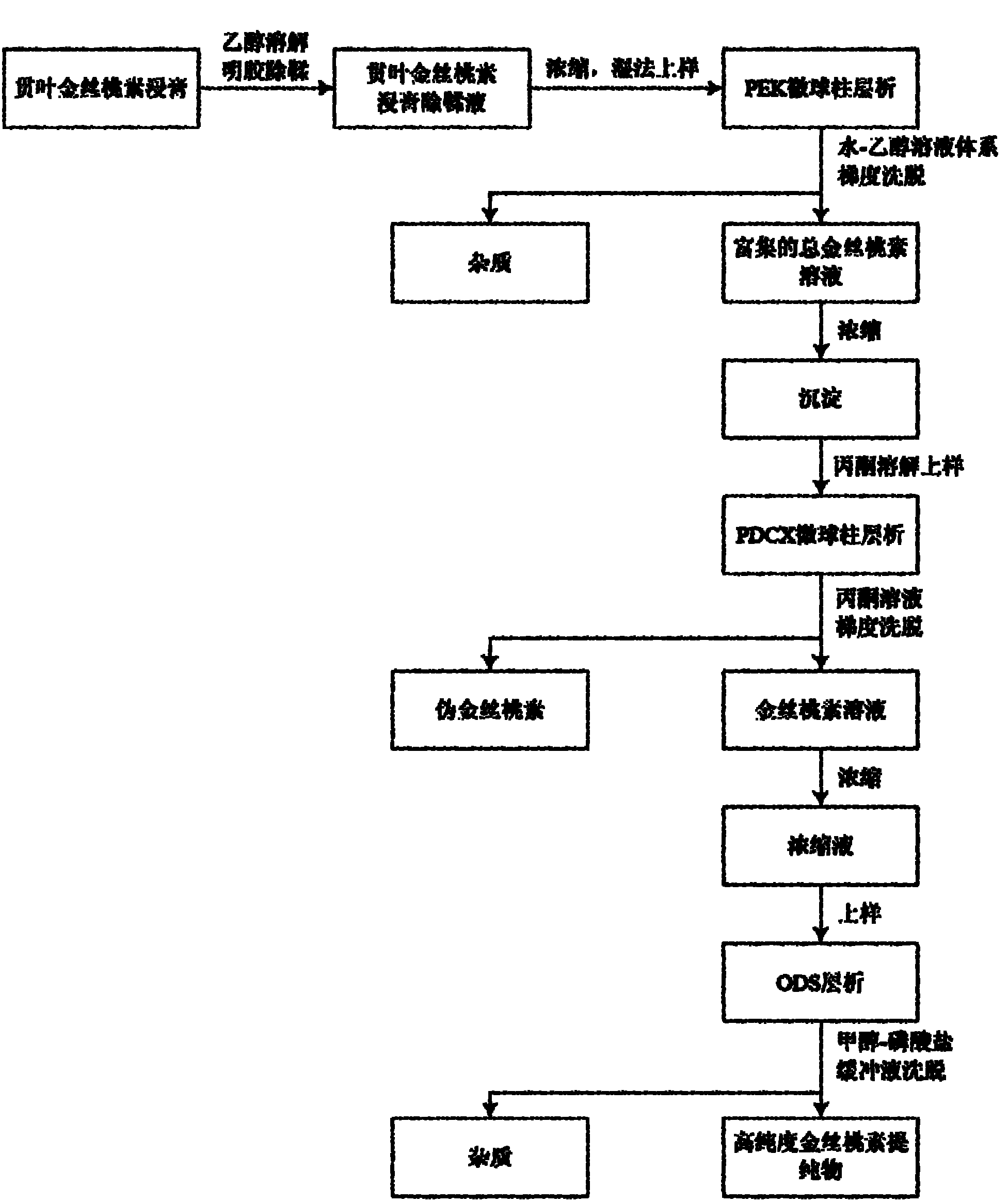

Method used

Image

Examples

Embodiment 1

[0029] Step (1): Weigh 100g of Hypericum perforatum extract, crush it, dissolve it in 600mL of 60% ethanol, and extract it ultrasonically for 30min, add 120mL of 10% gelatin solution, adjust the concentration of ethanol to 80%, let it stand for 10h, concentrate and filter to obtain Goldenseal perforatum Peach extract to remove tanning solution 350mL.

[0030] Step (2): PEK microsphere chromatography: suspend PEK microspheres with distilled water, and install them into a chromatography column with a specification of ?1cm×10cm by gravity sedimentation. After the PEK microspheres settle completely, equilibrate the column bed with 15mL distilled water. Take 8mL of Hypericum perforatum detanning solution prepared in (1), load the sample, and elute 16mL, 24mL, 16mL, 24mL, 48mL, 20mL, 56mL, collect 60% ethanol eluate, concentrate to obtain hypericin crude product, the content of hypericin measured by HPLC is 3.2%.

[0031] Step (3): PDCX microsphere chromatography: suspend PDCX micr...

Embodiment 2

[0034] Step (1): Weigh 100g Hypericum perforatum extract and crush it, dissolve it in 800mL of 60% ethanol solution, and then extract it ultrasonically for 30 minutes, add 200mL of 10% gelatin solution, adjust the ethanol concentration to 80%, let it stand for 10 hours, concentrate and filter it Hypericum leaf extract to remove tanning solution 450mL.

[0035] Step (2): PEK microsphere chromatography: suspend PEK microspheres with distilled water, and install them into a chromatographic column with a size of ?1cm×10cm by gravity sedimentation. After the PEK microspheres settle completely, equilibrate the column bed with 15mL distilled water, Add 6 mL of Hypericum perforatum detanning solution prepared in step (1), and then wash 12 mL, 20 mL, 12 mL, 20 mL, 40mL, 16mL, 42mL, collect 60% ethanol eluent, concentrate to obtain hypericin crude product, the content of hypericin measured by HPLC is 3.1%.

[0036] Step (3): PDCX microsphere chromatography: suspend PDCX microspheres in...

Embodiment 3

[0040] Step (1): Weigh 1000g of Hypericum perforatum extract and crush it, dissolve it with 6000mL of 60% ethanol solution and extract it ultrasonically for 30min, add 1200mL of 10% gelatin solution, adjust the ethanol concentration to 75%, let stand for 10h, filter and concentrate Hypericum leaf extract detanning liquid 2500mL.

[0041] Step (2): PEK microsphere chromatography: suspend PEK microspheres with distilled water, and install them into a chromatographic column with a specification of ?5cm×18cm by gravity sedimentation method. After the PEK microspheres settle completely, equilibrate the column bed with 700mL distilled water. Take 350 mL of Hypericum perforatum extract detanning solution prepared in step (1), load the sample, and wash with water, 10% ethanol solution, 30% ethanol solution, 40% ethanol solution, 60% ethanol solution at a flow rate of 10mL / min 525mL, 700mL, 875mL, 525mL, 1400mL, take the eluate of 60% ethanol solution, concentrate until no alcohol smel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com